Method for constructing normal piled concrete

A technology of rockfill concrete and construction method, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of complicated pre-buried grouting pipe process, etc., and achieve the effect of eliminating the chisel process, reducing the amount of cement, and simplifying the construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

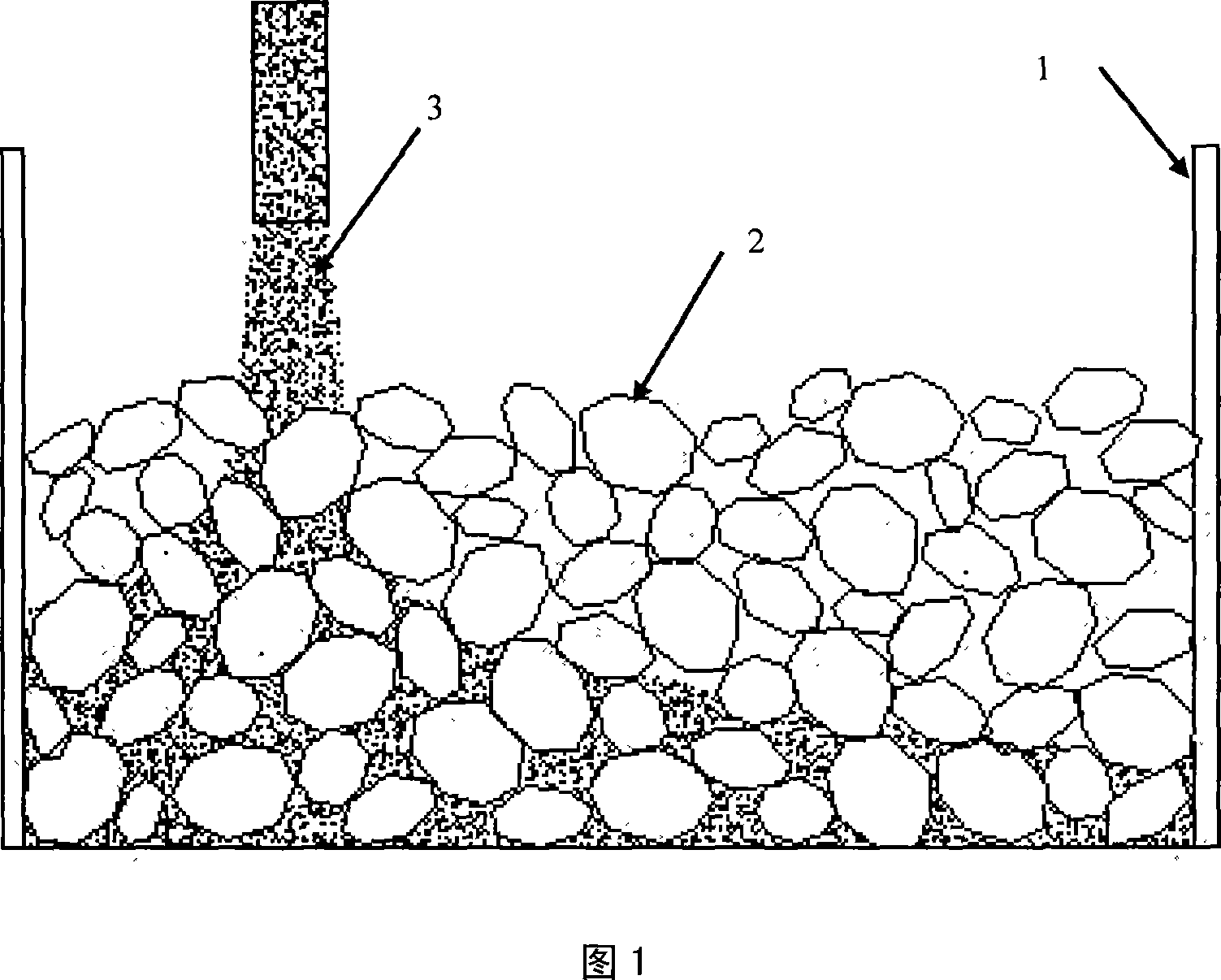

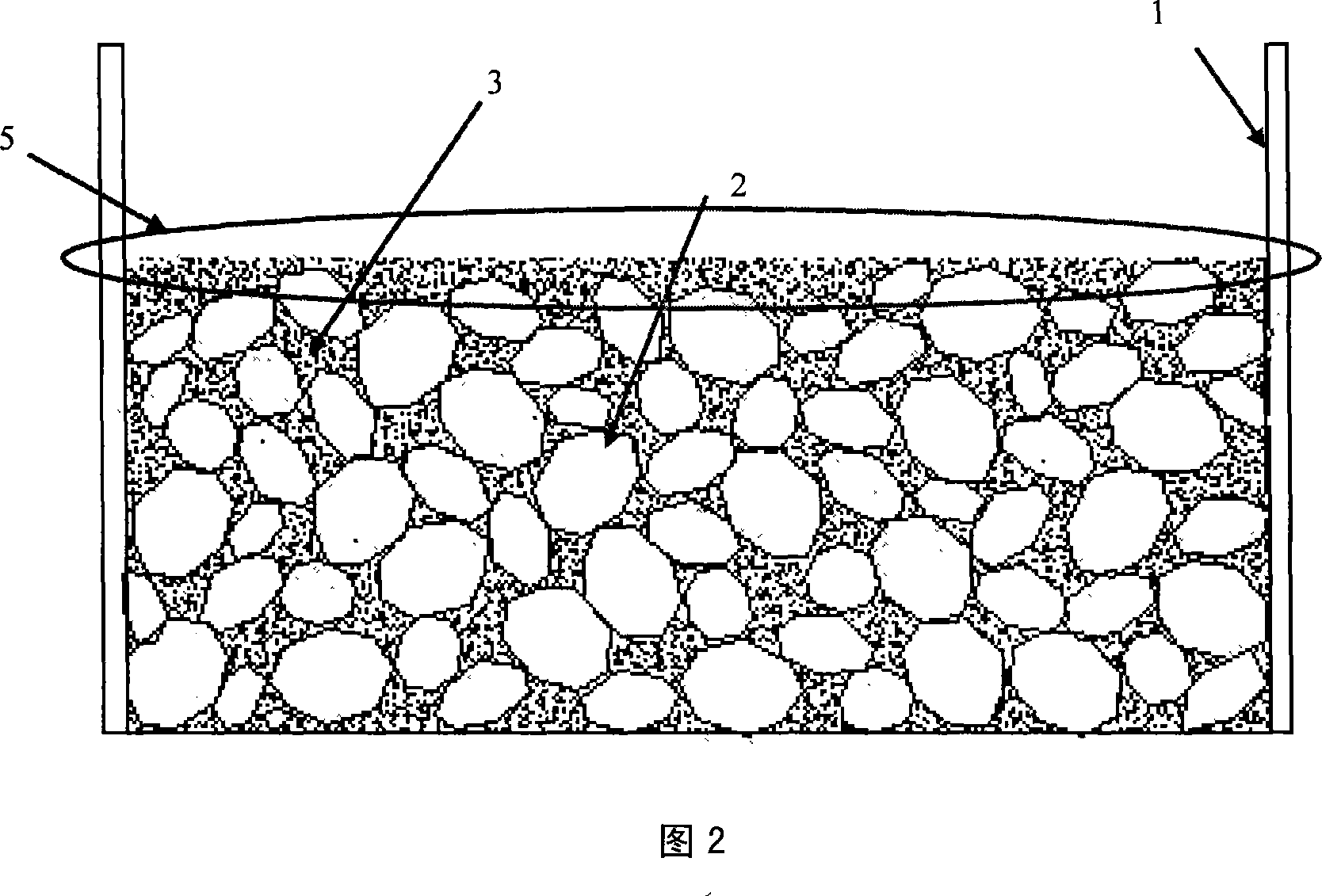

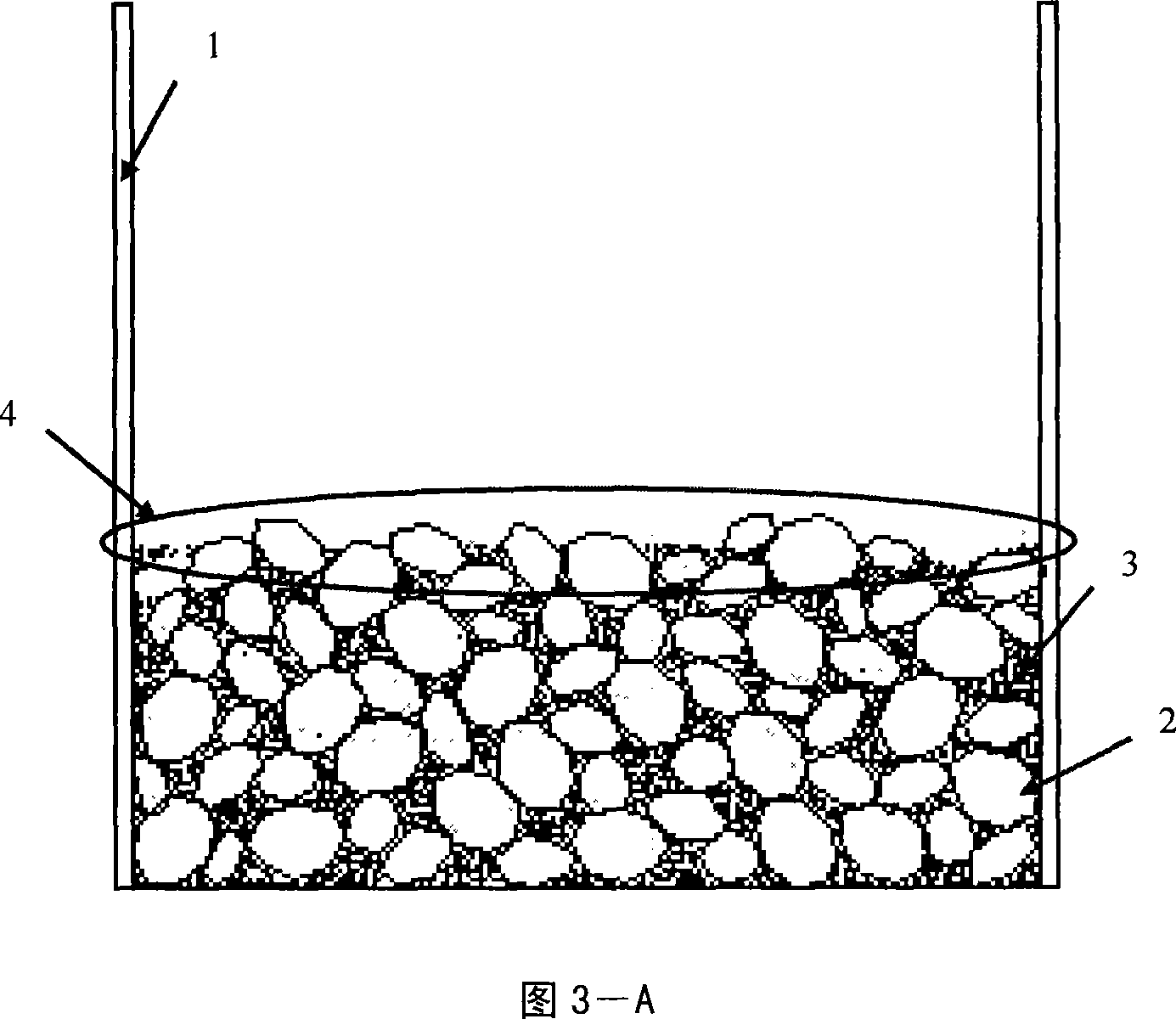

[0023] The present invention is based on the prior art. First, the rock-fill body is formed by natural accumulation of rocks, and then the self-compacting concrete meeting the performance requirements is directly poured from the surface of the rock-fill body. Under the guarantee of safety, rely on its own weight to fill the gaps between the stones. The specific method can be implemented as follows:

[0024] 1) Set formwork or formwork substitute 1 for the warehouse surface where rockfill concrete needs to be poured. The formwork substitute can be a closed structure such as a masonry wall or concrete wall with a certain rigidity and strength. The warehouse surface with natural barriers does not need to be provided with formwork or substitutes; formwork may not be provided for warehouse surfaces that already have barriers, and closed structures such as masonry walls or concrete walls may also be used instead of formwork.

[0025] 2) Use stones or pebbles with a particle size of...

Embodiment 1

[0035] In the specific implementation, the particle size of the used rockfill ranges from 15cm to 150mm. There are both block stones and pebbles in the rockfill. The particle size distribution is uneven, the rockfill can be transported by car, and then the rockfill can be piled up naturally. After natural accumulation, the void rate is about 40%; the thickness of the rockfill layer implemented is up to about 2.5m, usually 1.5m Left and right; about 0.8m thick masonry is used instead of the formwork, and the form removal process is omitted after forming. The self-compacting concrete with a slump of 260mm, an expansion of 600-700mm, and a V-shaped funnel passing time of 5-20s was used for pouring. warehouse, backhoe into the warehouse and other forms. The formed rock-fill concrete was tested by cutting observation, core drilling, and water pressure test, and the following results were obtained: the compactness of the rock-fill concrete is excellent, and the interior is complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com