Non-inflation and explosive-proof tyre

A run-flat tire and flush-free technology, used in non-pneumatic tires, tire parts, textiles, etc., can solve the problems of high manufacturing cost, heavy weight, and inability to maintain vehicle balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: With reference to accompanying drawings 1-2 and Figures 4-7. The non-inflatable explosion-proof tire comprises a tire carcass 1 and a tire crown 5, and the tire carcass 1 and the tire crown 5 can be manufactured by using the prior art. The tire carcass 1 is a rigid elastic body (the tire body includes a sidewall 3, a tread 2 and the surface opposite to the hub) and the tire carcass is provided with a reinforcing rib 4 (the reinforcing rib can be a stamping or hydraulic convex groove structure. , can also be externally welded or externally glued ribs), the tire carcass 1 protrudes and the reinforcing ribs 4 positioned on the carcass are made by stamping, oil pressure, etc. (or hydraulic pressure), and the tread 2 of the tire carcass is Reticular elastic body and the elastic steel plate is stamped and hydraulically pressed into a reticular elastic body by stamping, oil pressure and other processes. In order to improve the strength and elasticity of the mesh...

Embodiment 2

[0014] Embodiment 2: On the basis of Embodiment 1, the reticular elastic body on the tread 2 is formed by weaving elastic steel sheets 7 and the sidewall 3 of the tire carcass 1 is welded or snapped or riveted, and the elastic steel sheets 7 are pressed with Rib 8 (the rib 8 is a raised bar or a concave groove).

Embodiment 3

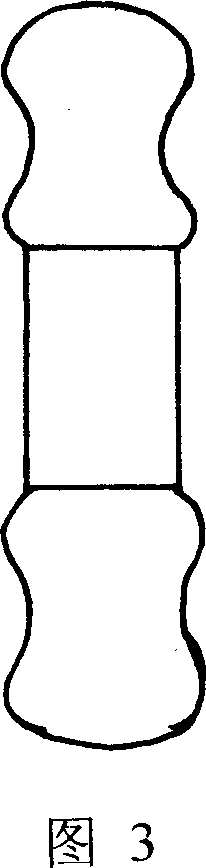

[0015] Embodiment 3: with reference to accompanying drawing 3. On the basis of Embodiment 1, the sidewall 3 of the tire carcass 1 is recessed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com