Improvement of data matrix code identification ratio inscribed on cutter

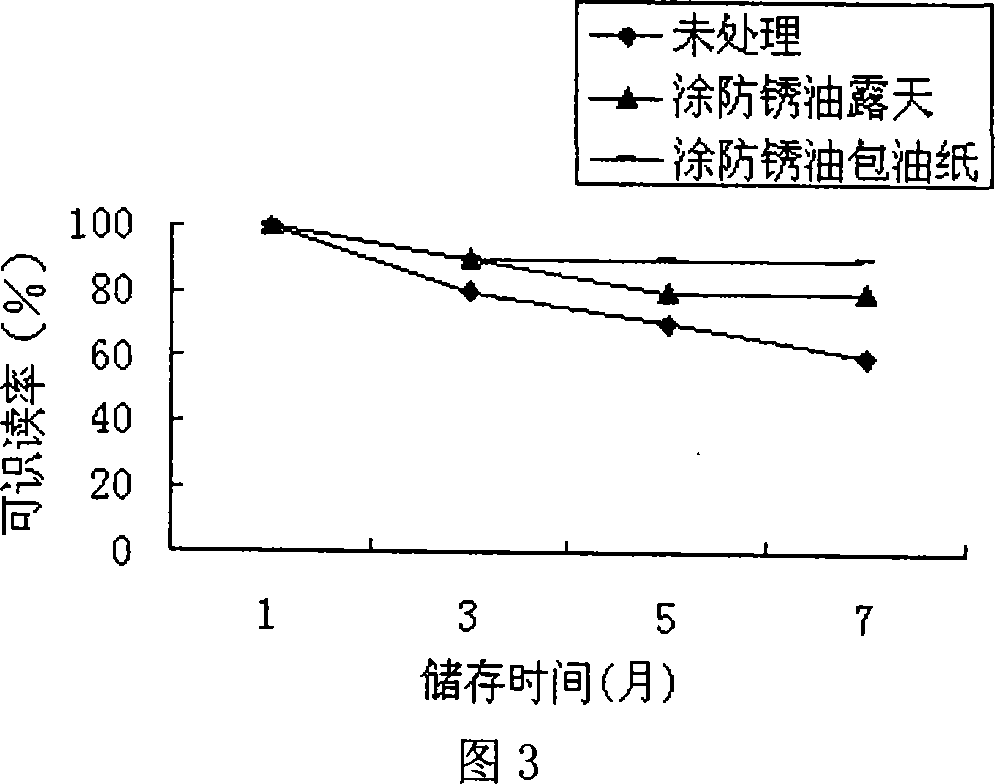

A data matrix code and marking technology, applied in the field of automatic identification of manufacturing resources, can solve the problems of low reading rate of tool data matrix code, etc., and achieve the effect of improving the reading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] This part lists the specific implementation of the method for improving the reading rate of the data matrix code on the tool. The object to be processed is a silver-gray 10mm drill bit: the marking content is ABCD1234.

[0037] The first step is to select the surface on which the barcode will be marked.

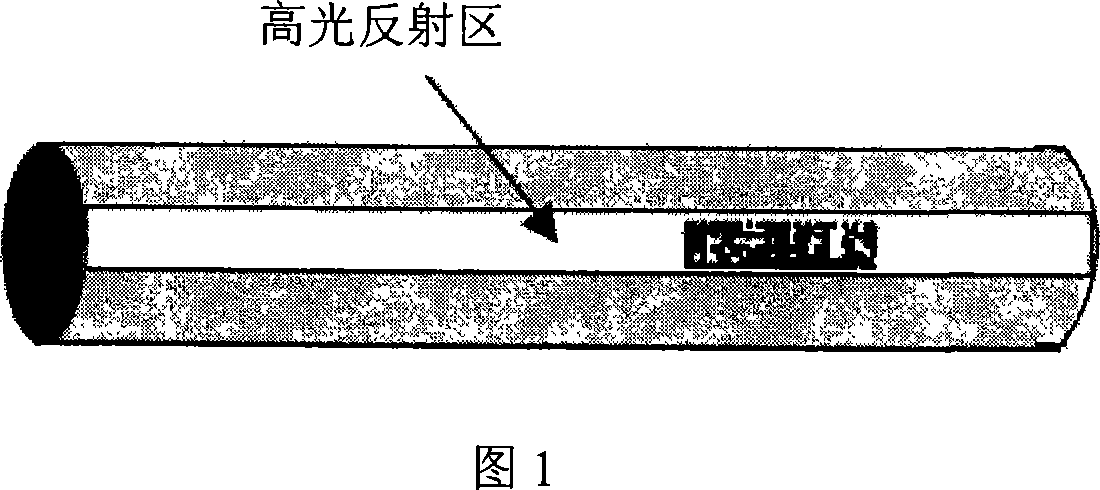

[0038] Since there is a central positioning hole on the end plane of the tool and the area is too small to mark the barcode, it is necessary to mark the outer cylinder of the tool. At this time, a rectangular data matrix code should be selected, and the length of the code is along the axis. Orientation, the width dimension should not exceed 16% of the diameter of the cylinder, see Figure 1.

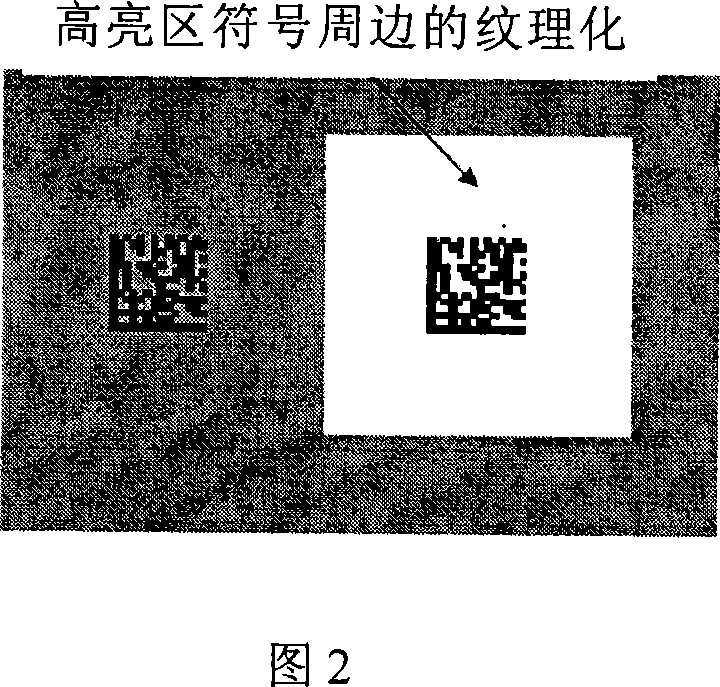

[0039] The second step is the roughness treatment of the marking surface.

[0040] The surface roughness Ra of the outer cylindrical surface of the tool is 0.8 μm, and the value is between 0.2 μm and 6.3 μm, which can be read normally. In order to ensure a high success rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com