Method and clamp for processing non-turning L-shape notch on optical lens

An optical lens and non-rotating technology, which is applied in optics, lenses, optical components, etc., can solve the problem of inability to process non-rotating L-shaped notch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

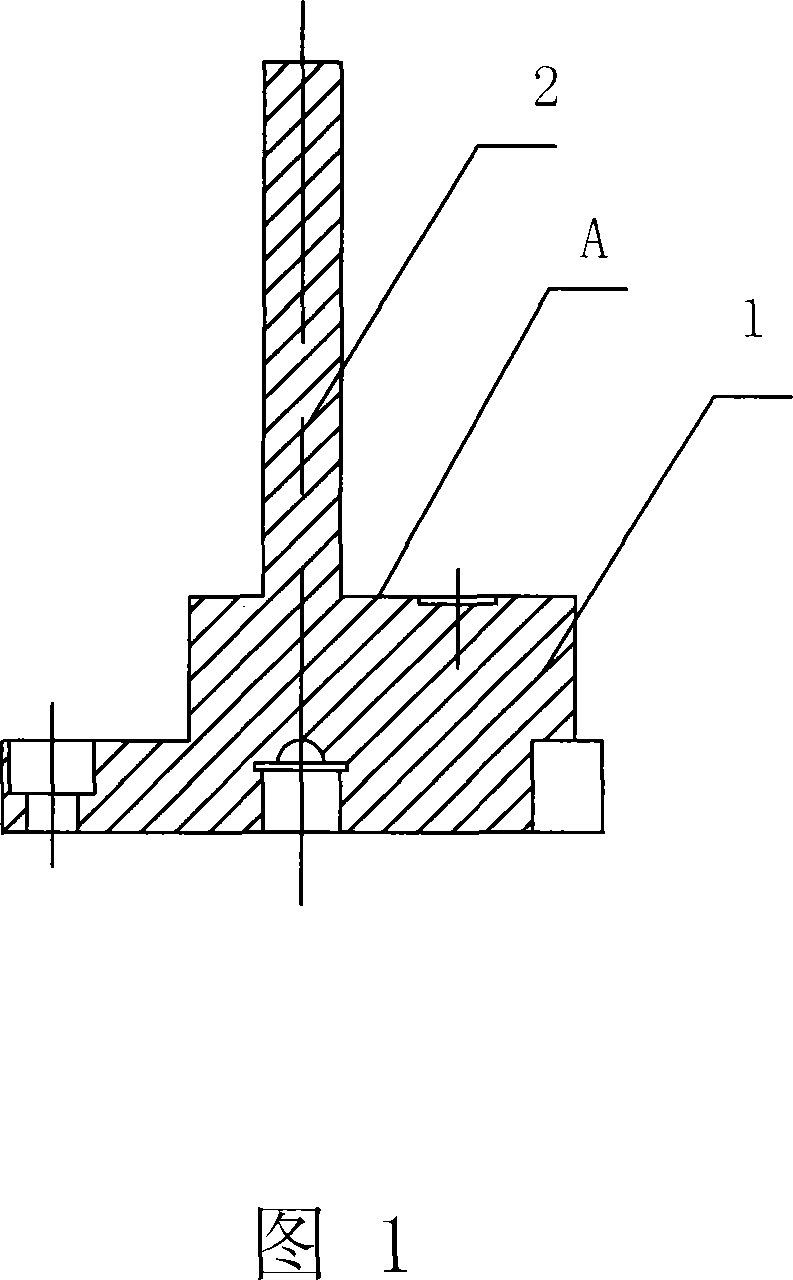

Image

Examples

Embodiment 1

[0037] Use this method on the PR-150 prism milling machine to process the L-shaped notch with the following precision:

[0038] ●L-shaped notch step thickness 4±0.02;

[0039] The parallelism between the two sides of the L-shaped notch step is 0.01;

[0040] ● L-shaped notch width 17 ± 0.05.

[0041] The process of processing is as follows:

[0042] (1) Clean fixtures and parts to be processed.

[0043] (2) To bond the parts, place the fixture and the processed part on the electric heating plate, slowly heat it to the temperature 70 ℃ ~ 80 ℃ where the glue strip wax can just melt, and coat the bonding surface of the fixture and the processed part with a A thin and uniform layer of wax strips, place the processed parts on the fixture, and align the edges.

[0044] (3) Naturally cool to room temperature.

[0045] (4) It is processed by a prism milling machine. The processing state is that the rotation center of the grinding wheel is consistent with the central axis of the p...

Embodiment 2

[0120] Use this method on the PR-150 prism milling machine to process the L-shaped notch with the following precision:

[0121] ●L-shaped notch step thickness 4±0.02;

[0122] The parallelism between the two sides of the L-shaped notch step is 0.01;

[0123] ● L-shaped notch width 17 ± 0.05.

[0124] The process of processing is as follows:

[0125] (1) Clean fixtures and parts to be processed.

[0126] (2) To bond the parts, place the fixture and the processed part on the electric heating plate, slowly heat it to the temperature 70 ℃ ~ 80 ℃ where the glue strip wax can just melt, and apply a coating on the bonding surface of the fixture and the processed part A thin and uniform layer of wax strips, place the processed parts on the fixture, and align the edges.

[0127] (3) Naturally cool to room temperature.

[0128] (4) Programming

[0129] Tool number: 7

[0130] Outside diameter 0D[mm]: 100

[0131] Inside diameter ID [mm]: 89.9

[0132] Tool Ref.diameter TR[mm]: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com