Sheet material cutting method

A cutting method and cutting direction technology, applied in electrical components, metal processing, circuits, etc., can solve the problems of easy breakage at the end of the blade, wrinkling of the sheet S, breakage of the wafer W, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Now, embodiments of the present invention will be described with reference to the drawings.

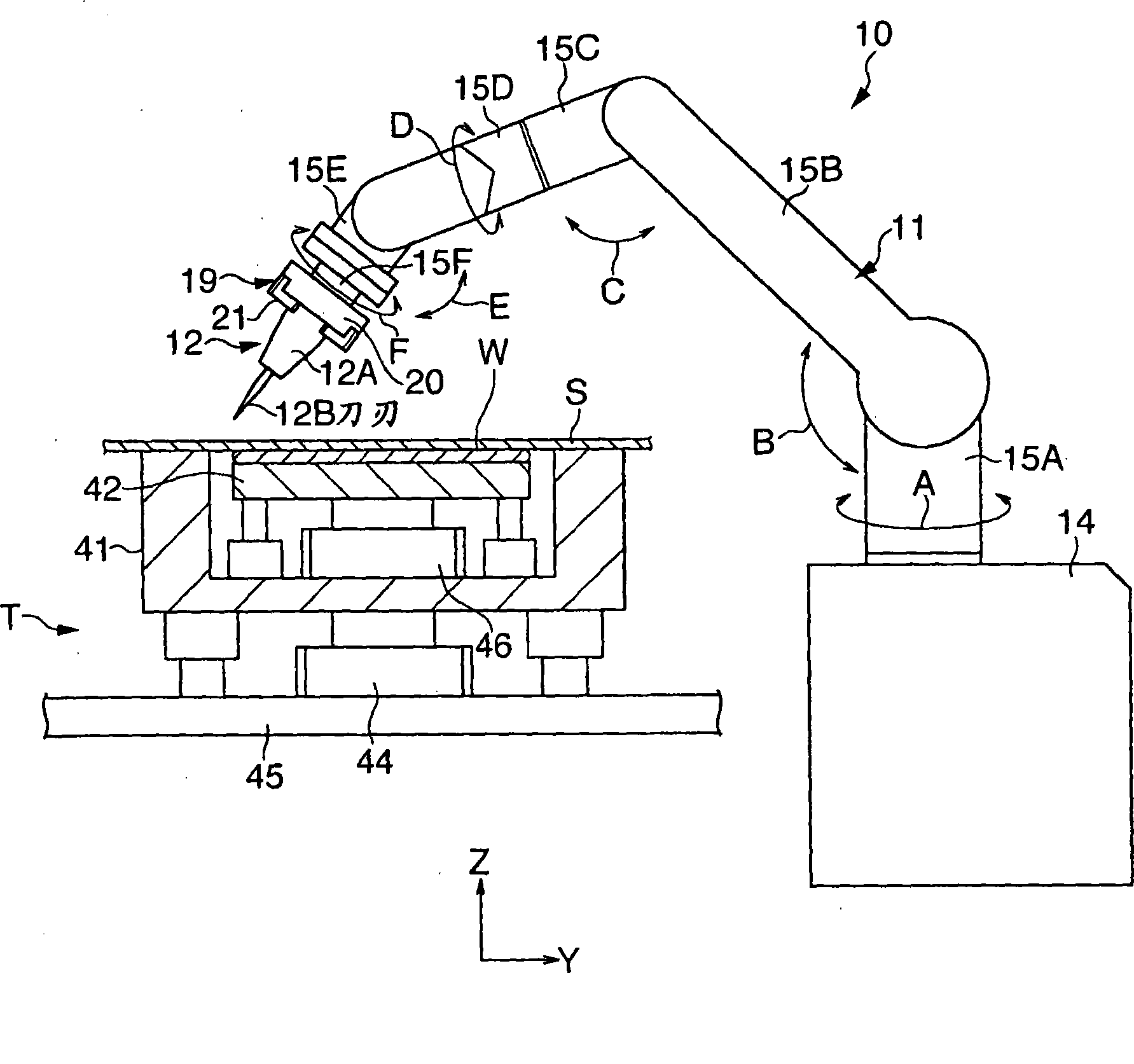

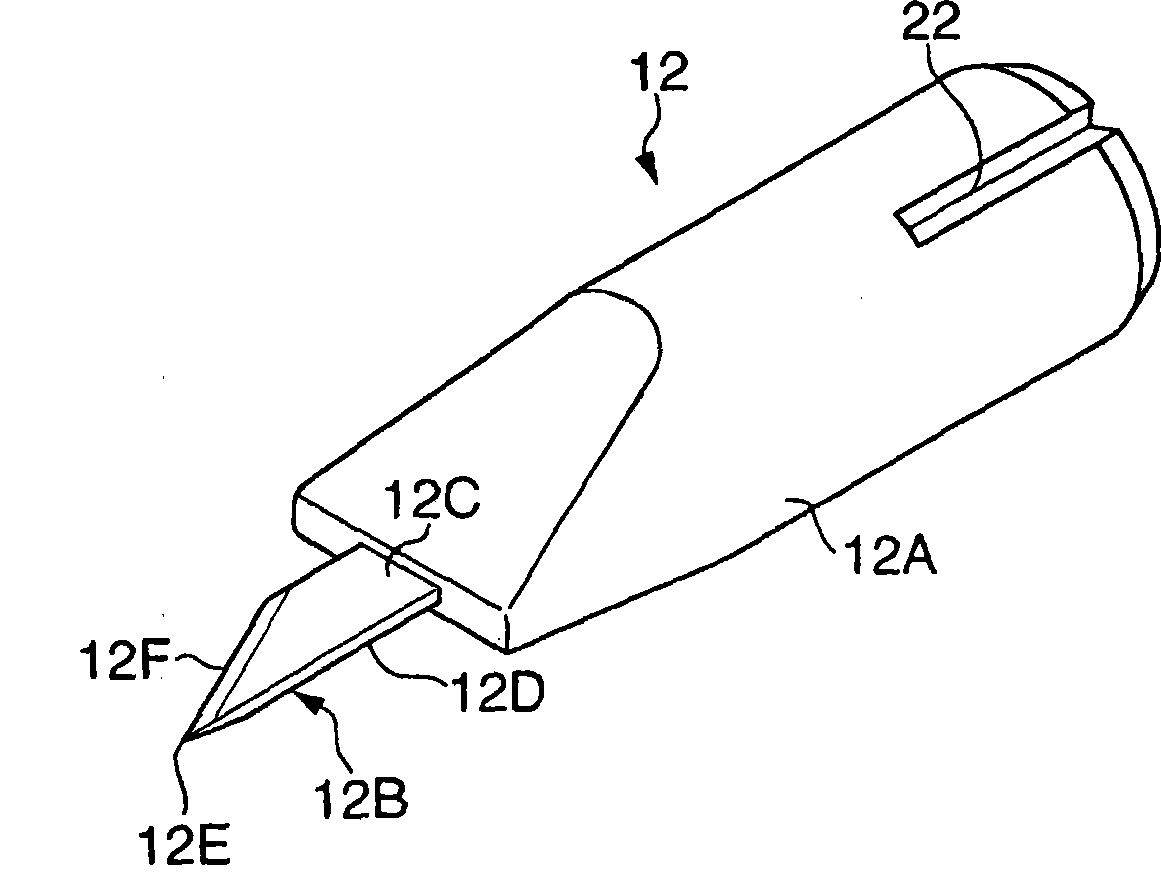

[0047] figure 1 is a schematic front view of a sheet cutting apparatus 10 and a table T provided together with the sheet cutting apparatus 10 according to an embodiment of the present invention. The table T supports the wafer W as a plate-like object in a substantially horizontal posture, so that the adhesive protective sheet S is stuck to the upper surface (circuit surface) of the wafer W, wherein the wafer W has a substantially circular shape in plan view. shaped shape. refer to figure 1 , the sheet cutting apparatus 10 includes a multi-joint manipulator 11 and a blade 12 held by the manipulator 11 .

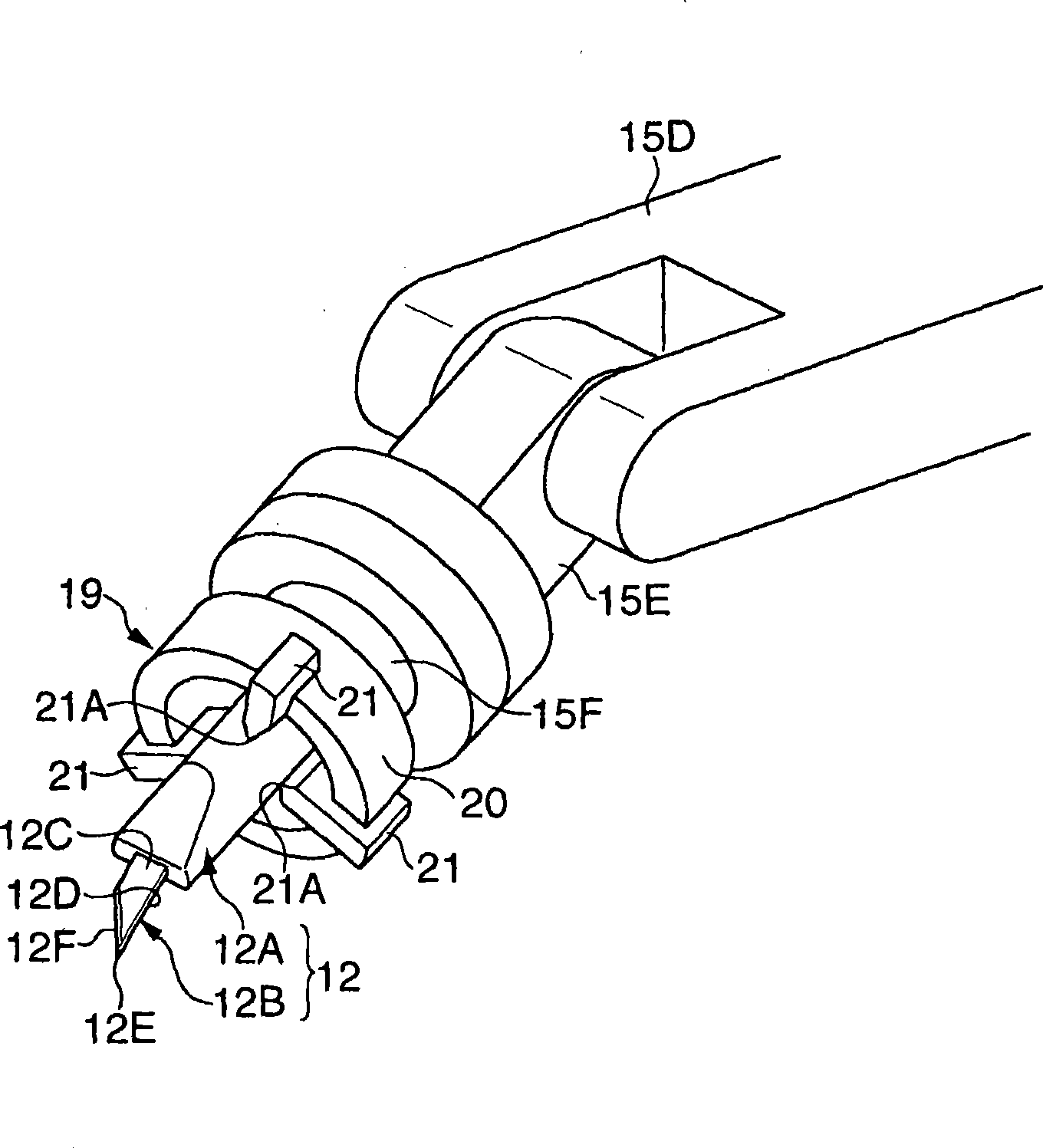

[0048] The manipulator 11 includes a base portion 14, first to sixth arms 15A-15F mounted to the upper surface side of the base portion 14 to rotate in directions indicated by arrows A-F, respectively, and a front end connected to the sixth arm 15F (that is, the manipulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com