Protection film separation head unit and equipment with same

A technology of protective film and head unit, applied in the direction of polarizing elements, layered products, chemical instruments and methods, etc., can solve the problems of increased time, inability to perform protective film separation steps smoothly, and prolonging the overall bonding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to gain a full understanding of the invention, its advantages and objects achieved by its embodiments, refer to the accompanying drawings, which illustrate preferred embodiments of the invention. Hereinafter, the present invention will be described in detail by explaining preferred embodiments of the invention with reference to the accompanying drawings. The same reference numerals in the figures denote the same elements.

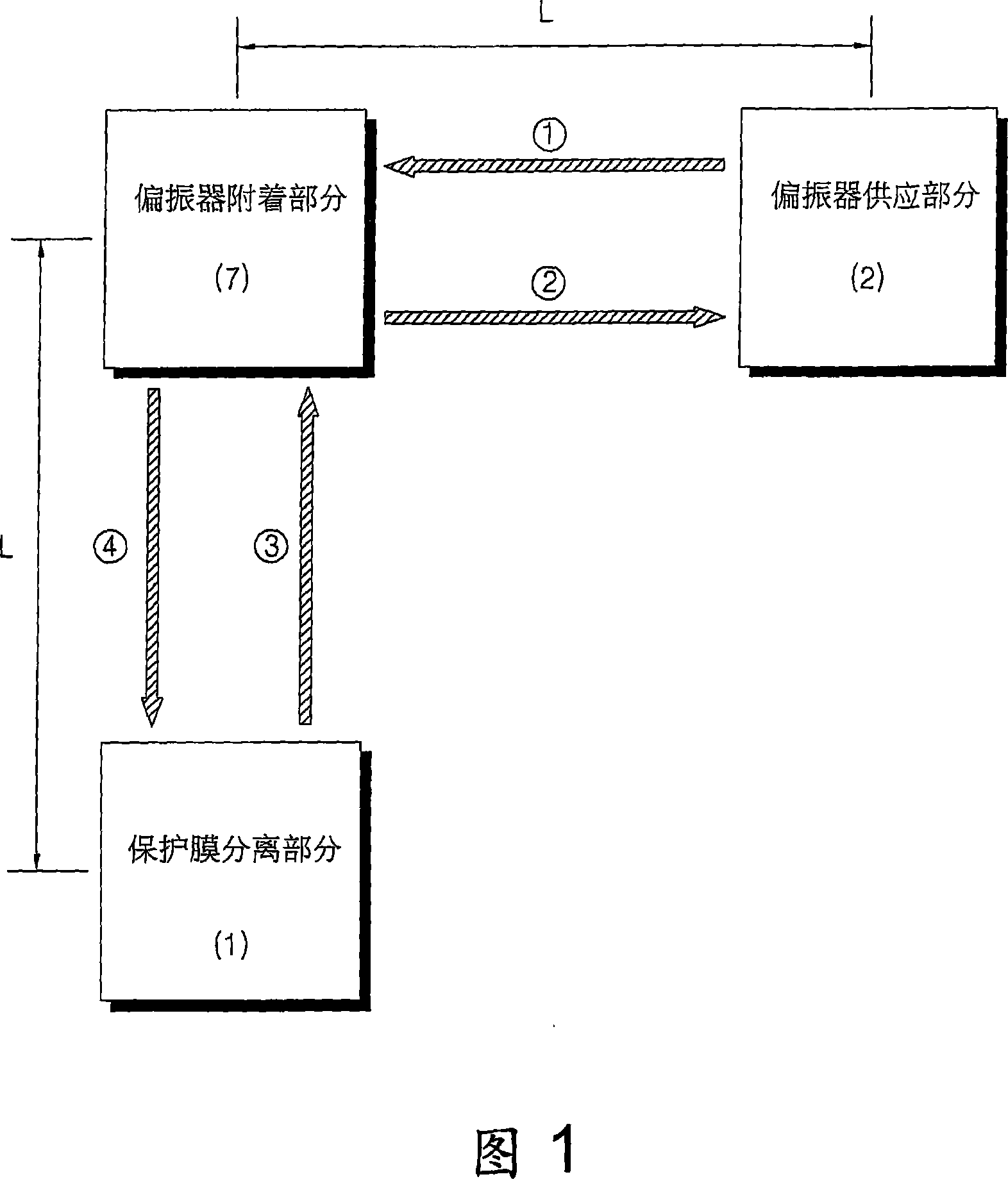

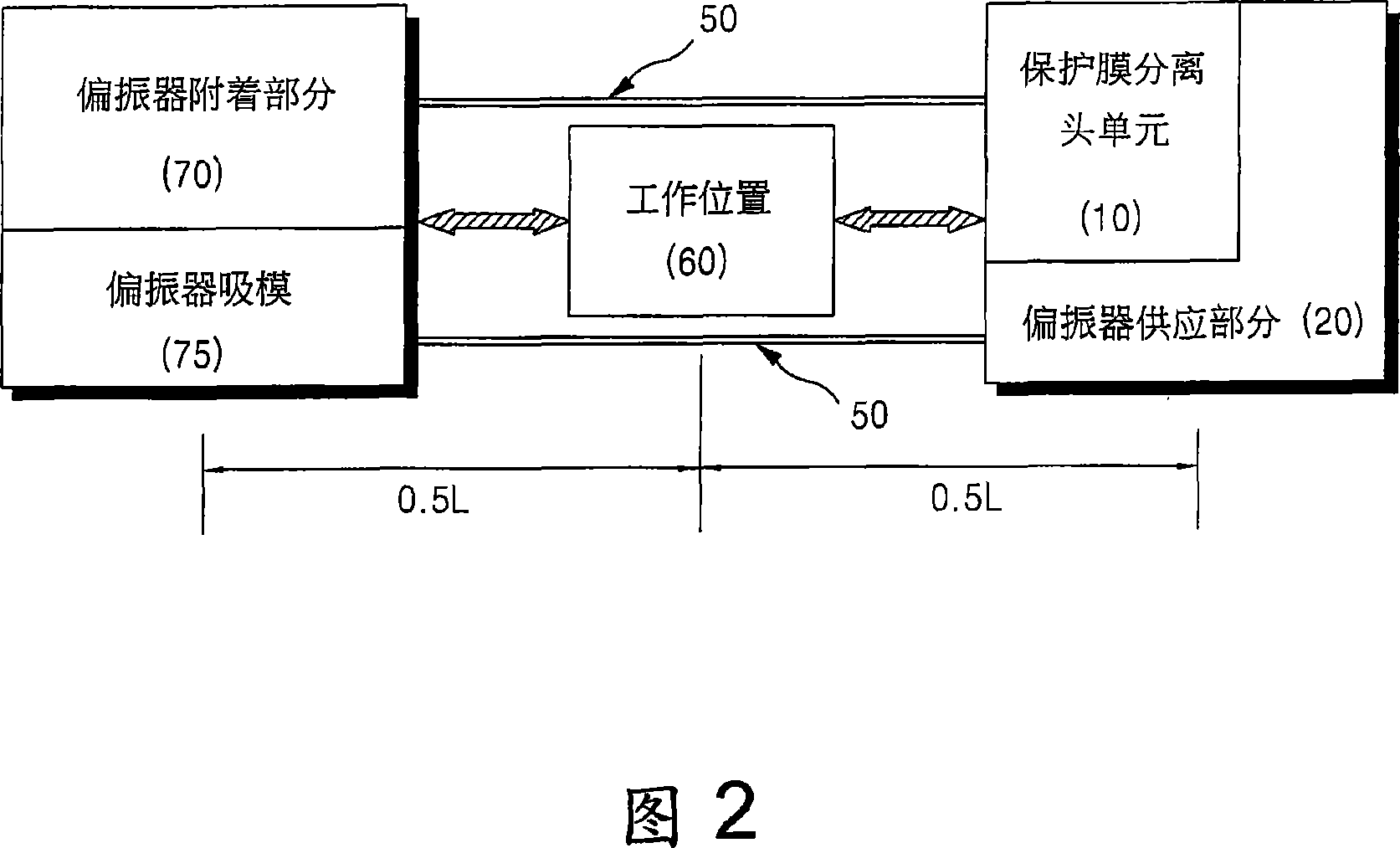

[0046] FIG. 2 illustrates the configuration of a polarizer attaching device according to an embodiment of the present invention. FIG. 3 is a partially enlarged perspective view of the polarizer attaching device of FIG. 2 .

[0047] Referring to FIGS. 2 and 3, the polarizer attaching device according to the present embodiment includes: a polarizer attaching part 70 to which a movable polarizer suction mode 75 is coupled; and a polarizer supply part 20, a protective film The separation head unit 10 is integrally coupled to the polarizer supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com