Thin heat radiation machine

A heat dissipation mechanism and thin technology, which is applied in cooling/ventilation/heating transformation, instrument cooling, instrument and other directions, can solve the problems of limited total thickness, miniaturization of cooling fans, etc., and achieve the effect of reducing activation power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

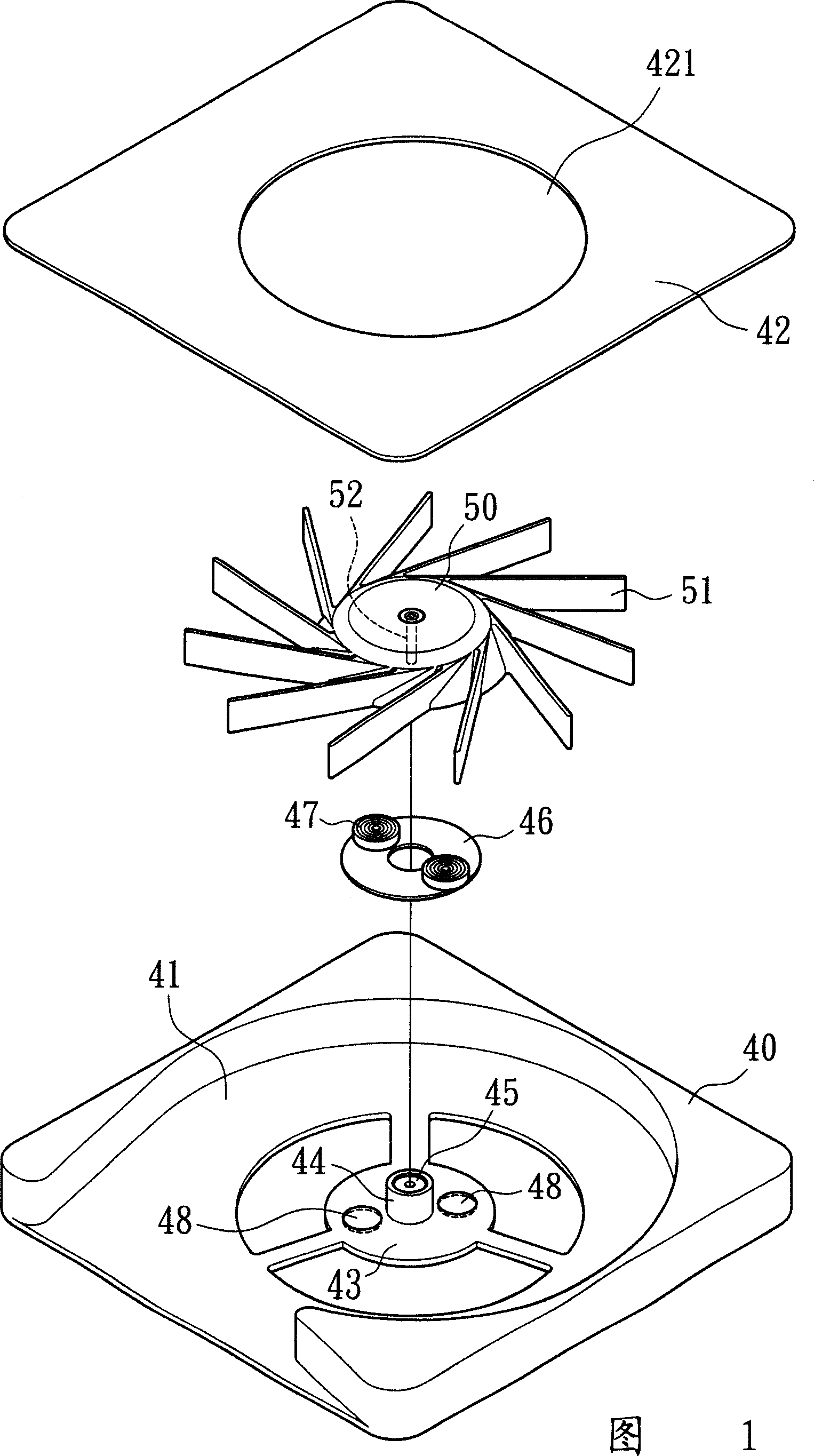

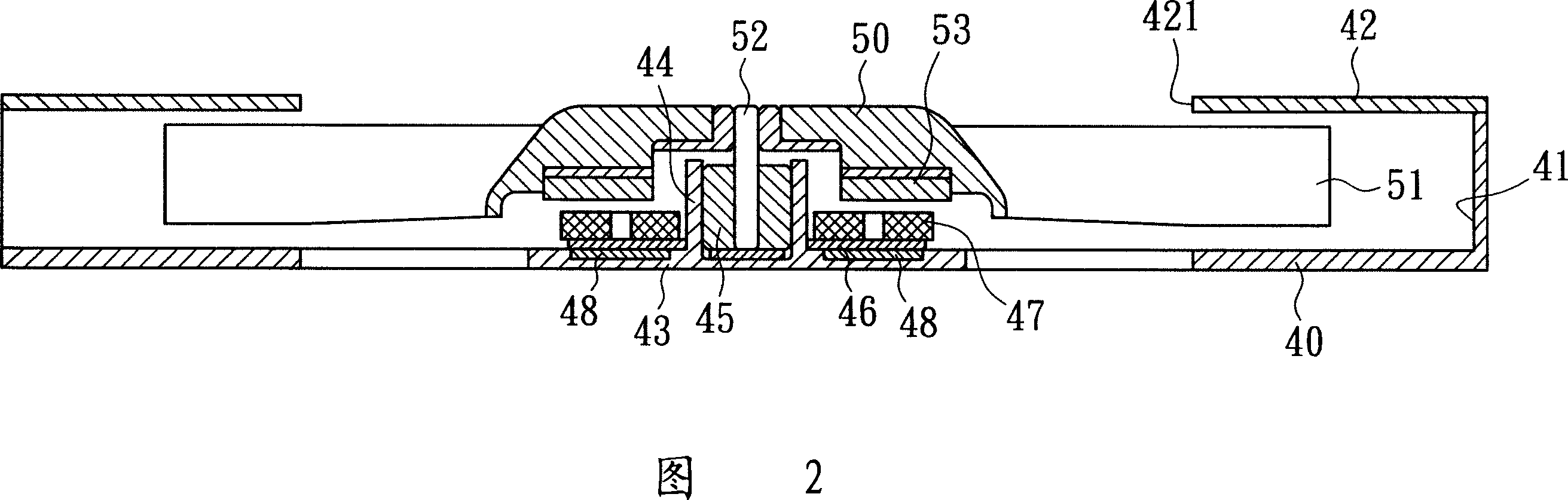

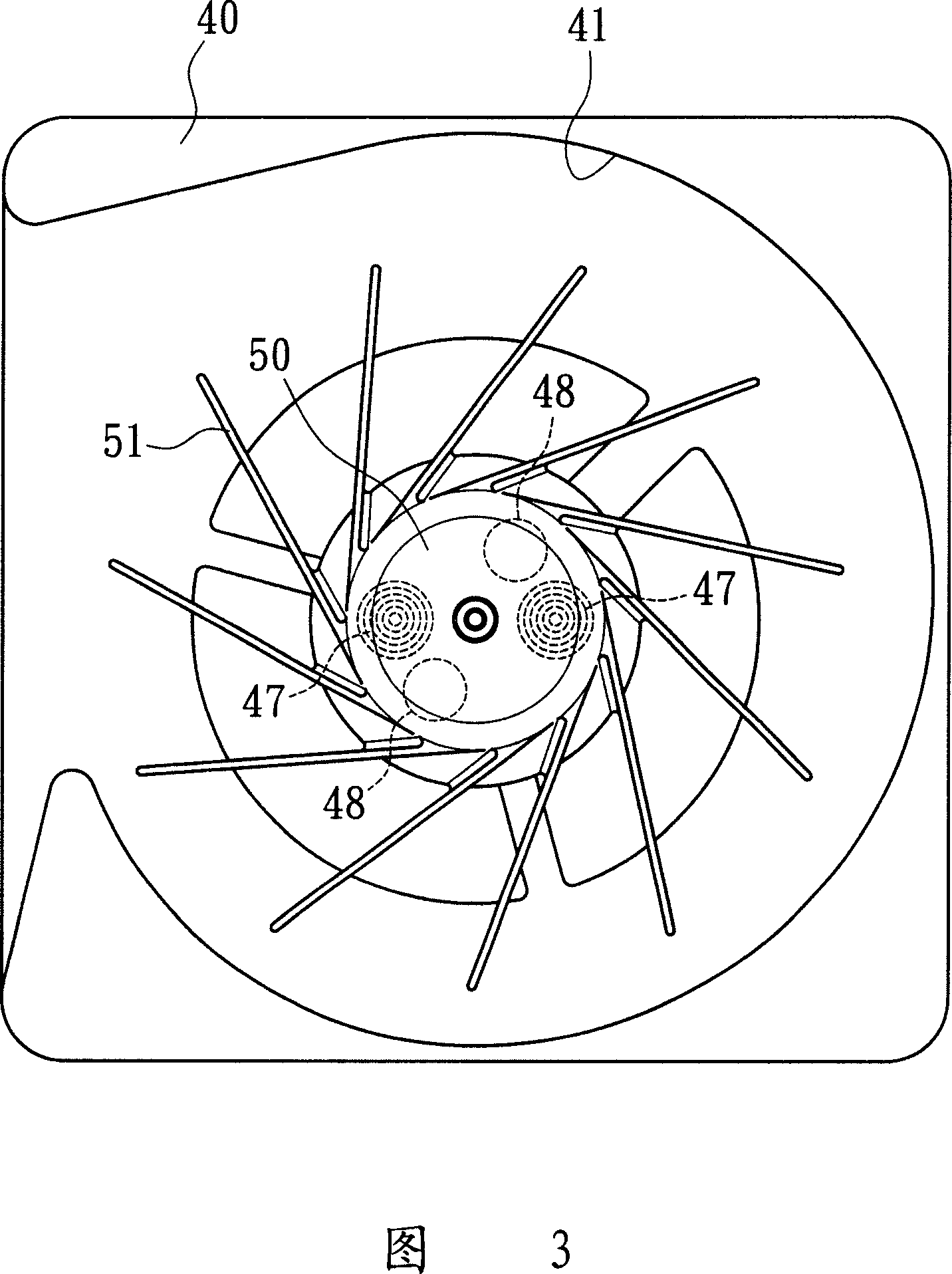

[0020] Referring to Fig. 1, the first embodiment of the present invention, the thin heat dissipation mechanism mainly includes: a frame body 40, which has an accommodating space 41 for a fan wheel rotor 50 to be arranged therein, above the frame body 40 The cover is provided with a cover plate 42, and the cover plate 42 is provided with an air inlet 421 corresponding to the fan wheel rotor 50, so when the fan wheel rotor 50 rotates, the several blades 51 extended on its periphery can drive the airflow to be sucked from the air inlet 421 , and then blow out from the air outlet on one side of the accommodating space 41 to dissipate heat from the electronic heating element;

[0021] Please refer to FIG. 2, the base 43 for installing the fan wheel rotor 50 is provided at the bottom of the accommodation space 41, the circuit board 46 and the coil 47 are provided on the base 43, and a shaft tube 44 protrudes from the center of the base 43. The shaft tube 44 has a built-in bearing 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com