Hot expansion continuous microflow high pressure gradient pump for high-performance liquid chromatographer

A high-performance liquid chromatography and thermal expansion technology, applied in the field of thermal expansion continuous micro-flow high-pressure gradient pump, can solve problems such as difficulty, change of split ratio, and reduction of solvent usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

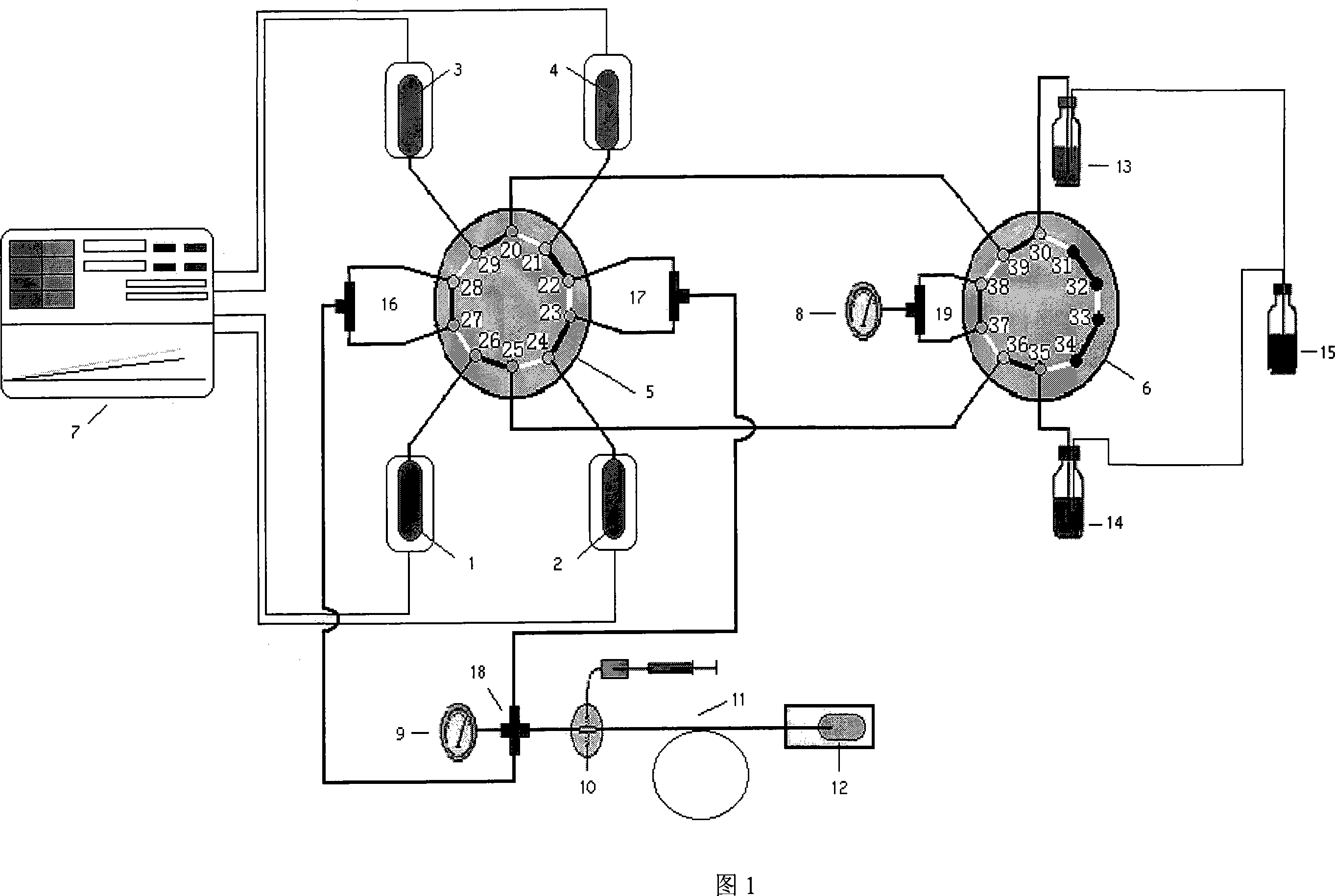

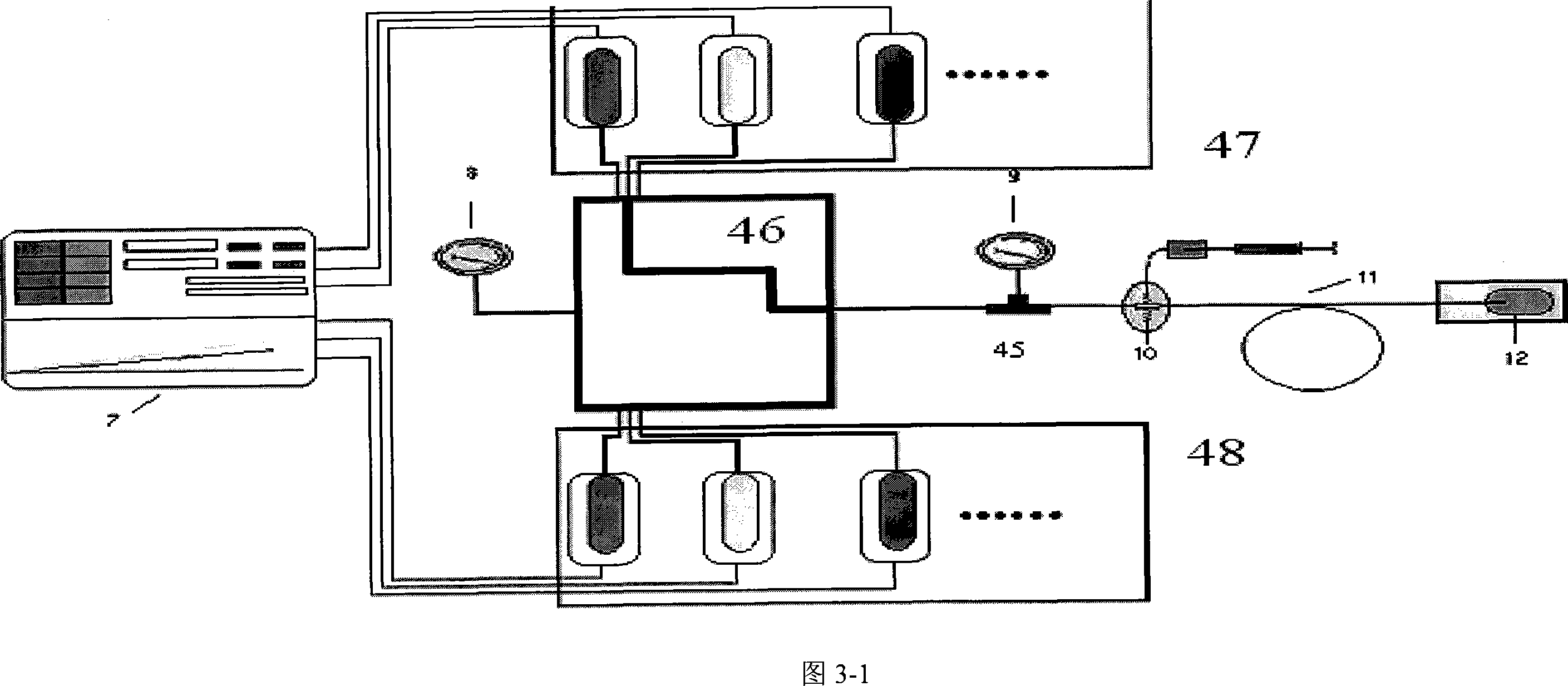

[0046] 1. Prepare a pump cavity of a stainless steel tube with an inner diameter of 5 mm and a length of 56 mm, and the volume of the pump cavity is 1100 μL.

[0047] 2. Using a fused silicon capillary with an inner diameter of 250 μm as the liquid storage capillary, the design length is 3 m, and the liquid storage volume is 147.2 μL. A single pump can work for more than one hour without switching at a flow rate of 2 μL.

[0048] 3. The liquid storage bottle is connected to the ten-way valve 6 through a polytetrafluoroethylene tube with a filter on the head. The ten-way valve, three-way, four-way and pressure sensor are all connected by 7μm inner diameter stainless steel pipes, and the length should be as short as possible.

[0049] 4. Computers, sampling devices, chromatographic columns, detectors, etc. use common products, use control circuit boards to communicate with temperature sensors, pressure sensors and computers, and use micro-flow pump control software to make the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com