Impact machine direct testing method and dedicated standard impact body

An impact testing machine and impact body technology, applied in impact testing, machine/structural component testing, measuring devices, etc., can solve the problems of inability to determine the accuracy of the impact testing machine, inability to directly verify the impact testing machine, etc., and achieve manufacturing costs. Low, simple and convenient operation, high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Carry out direct verification on the 0~150J energy section of an impact testing machine.

[0033] Select the high, middle and low points of 140J, 80J and 30J. First of all, empty swing impact, the purpose is to zero. Raise the pendulum, turn the pointer of the dial to the place with the maximum energy for impact, adjust the dial on the dial, so that the pointer is at zero when the impact is empty (logarithmic display dial, can automatically control zero adjustment, raise the pendulum to the maximum energy position).

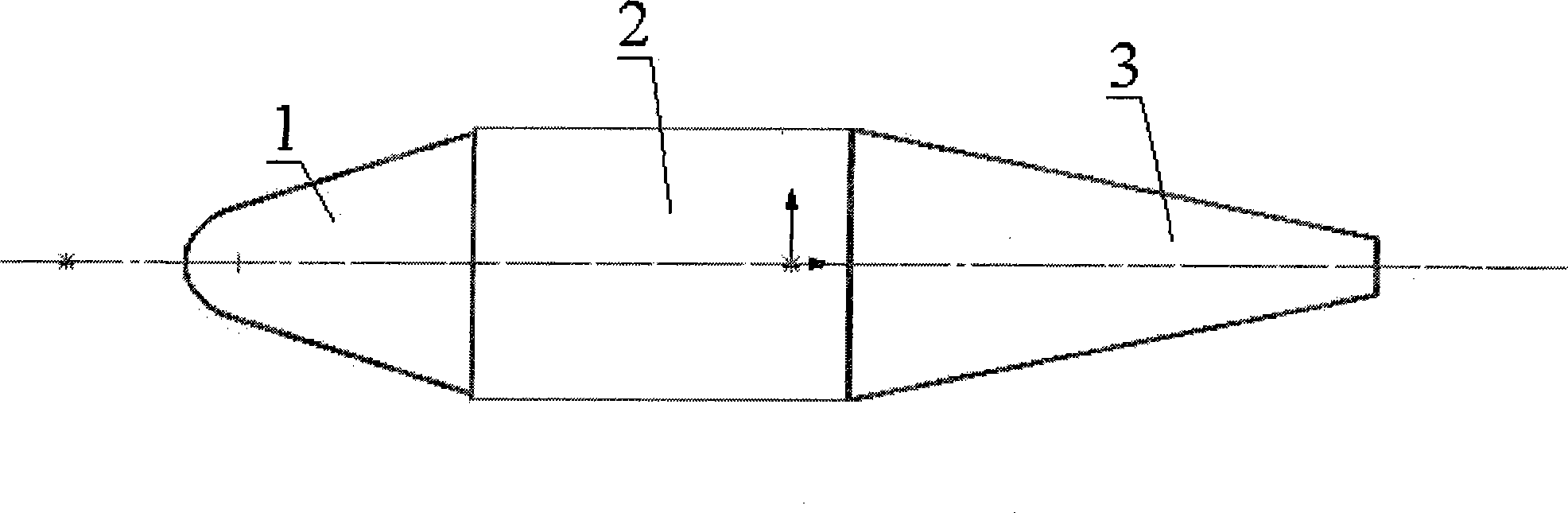

[0034] A 4.00kg standard impact body is used to verify the energy of 140J. By adjusting the counterweight 2, put the 4.00kg standard impact body on the fixed base bracket, and determine the height and horizontal position of the standard impact body by adjusting the bolts on the base, so that the impact section of the standard impact body Φ10 and the impact blade can effectively impact the blade Positive. Put the pendulum to impact, when the standard im...

Embodiment 2

[0039] Carry out direct verification on the 0~300J energy section of an impact testing machine.

[0040] Select the high, middle and low points of 280J, 150J and 30J. First of all, empty swing impact, the purpose is to zero. Raise the pendulum, turn the pointer of the dial to the place of maximum energy for impact, adjust the dial on the dial, so that the pointer is at zero when the impact is empty (the logarithmic display dial can automatically control zero adjustment, raise pendulum to the maximum energy position).

[0041]Use 8.50kg standard impact body to test the energy of 280J. By adjusting the counterweight 2, put the 8.50kg standard impact body on the fixed base bracket, and determine the height and horizontal position of the standard impact body by adjusting the bolts on the base, so that the impact section of the standard impact body Φ10 and the impact blade can effectively impact the blade Positive. Put the pendulum to impact. When the standard impact body flies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com