Carpentry machine tool used for log processing

A technology of woodworking machine tools and logs, applied in the field of woodworking machine tools for log processing, which can solve the problems of deformation, no exact solution found, easy rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For the sake of illustration, after the log is clamped on the machine tool, the direction parallel to the axis of the log is defined as the longitudinal direction, the horizontal direction perpendicular to the axis of the log is defined as the transverse direction, and the vertical direction perpendicular to the axis of the log is defined as the vertical direction.

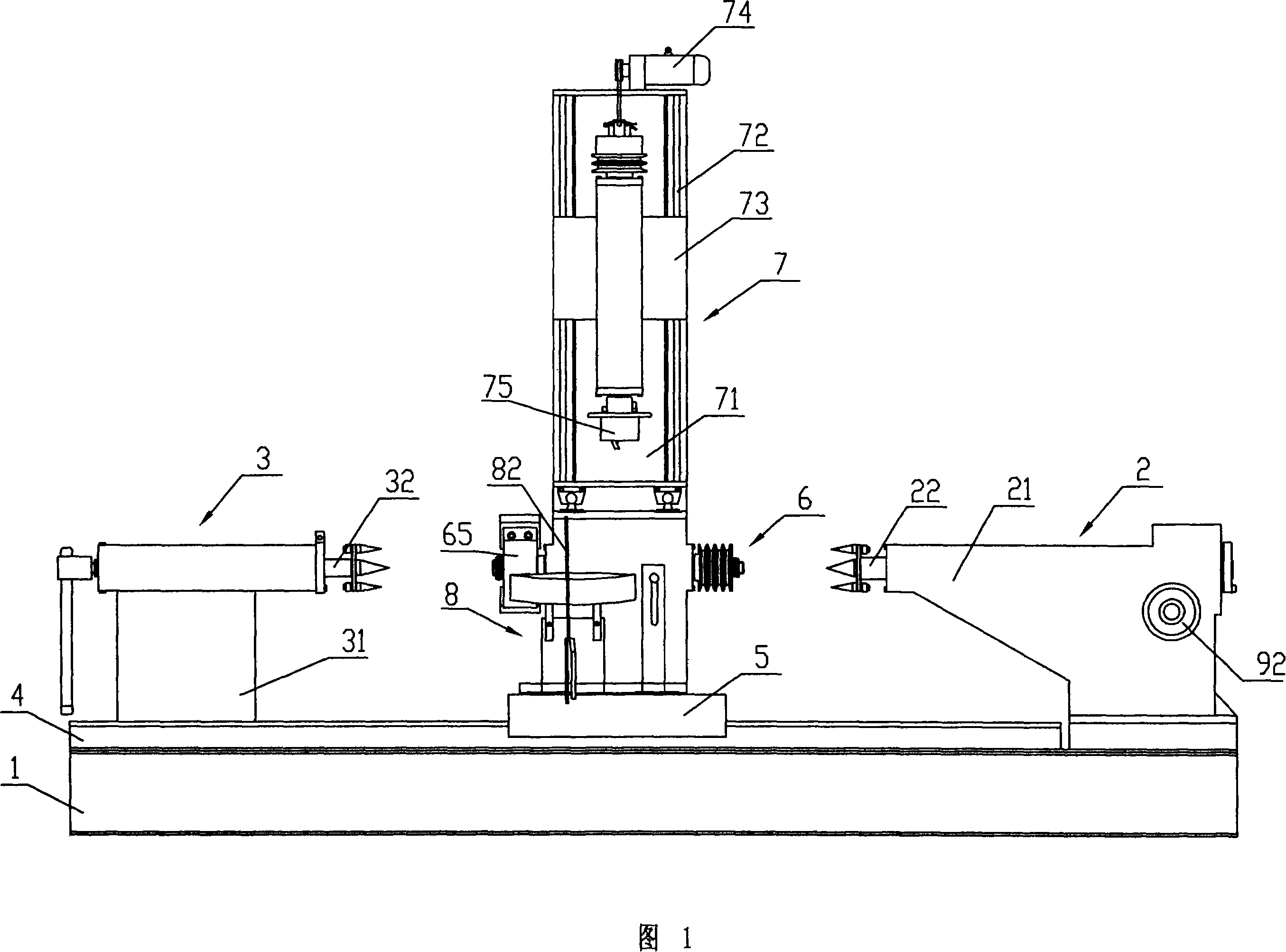

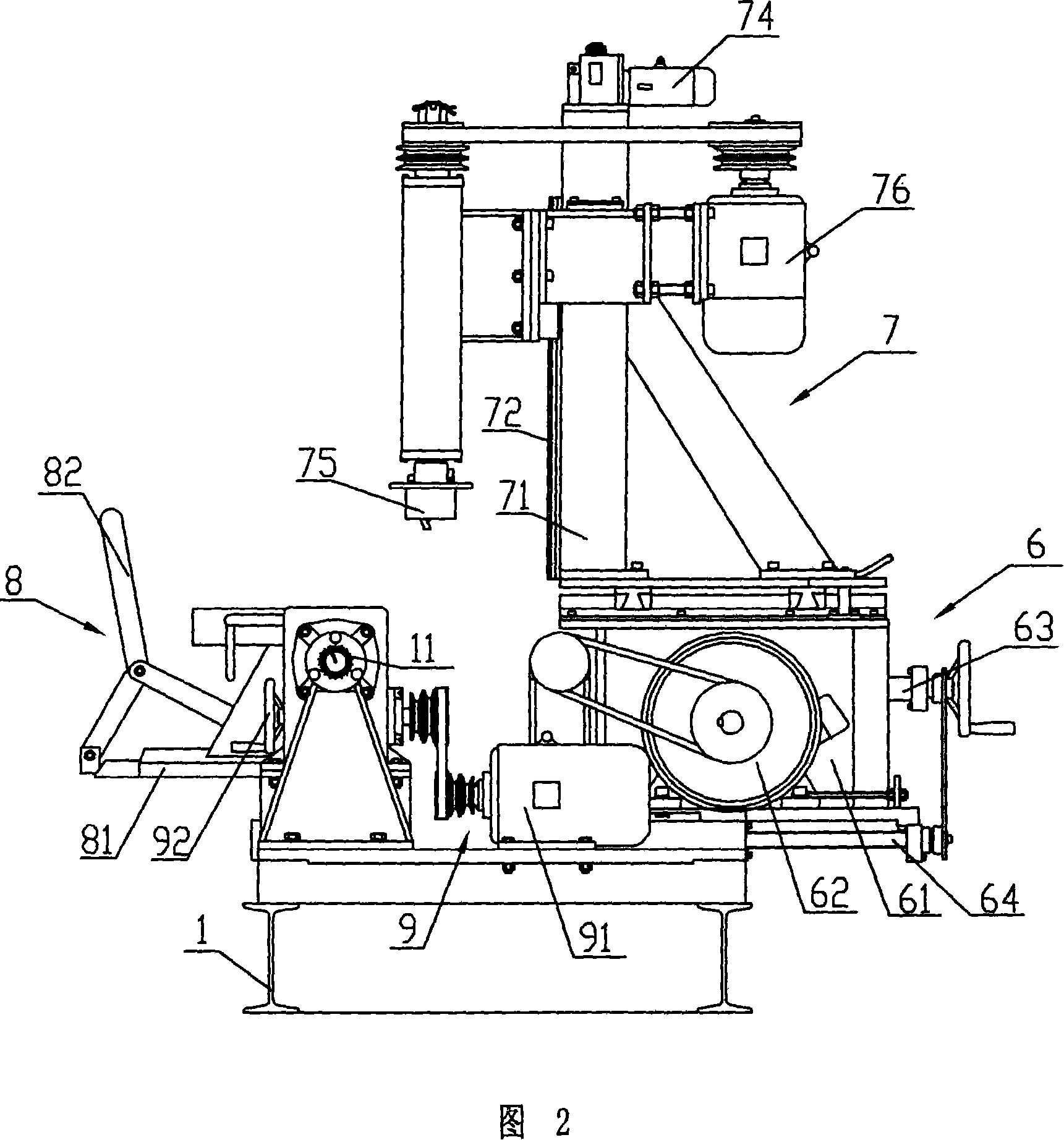

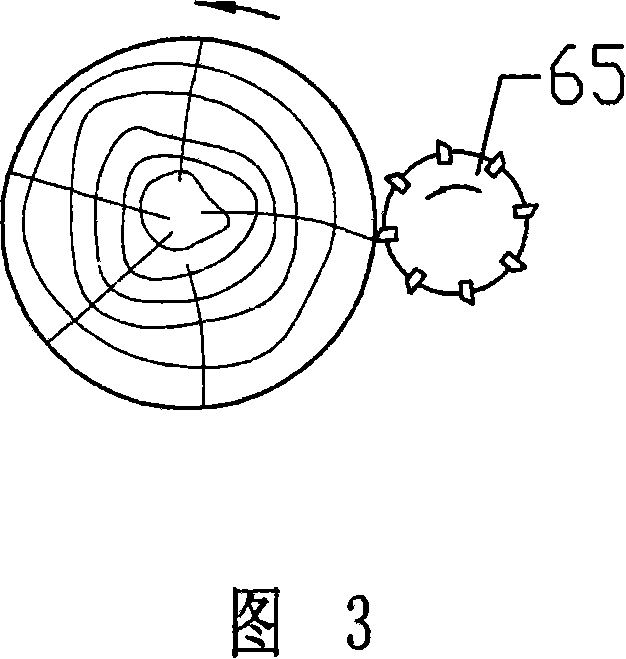

[0019] A woodworking machine tool for log processing, as shown in Figure 1 and Figure 2 together, it includes a machine base 1 provided with a longitudinal rail 4; a power tailstock 2 for supporting the log from both ends in the axial direction and driving it to rotate and supporting tailstock 3, a sliding seat 5 that is located between the power tailstock 2 and supporting tailstock 3 and can move along the longitudinal rail 4, a longitudinal feed power device that drives the moving of the sliding seat 5, and installs A horizontal milling device 6 capable of performing horizontal milling on the outer periphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com