Aromatic diacid ester diols and substituted carbamates thereof for minimizing deterioration of polyurethane foams

A technology of di-ester diol and tertiary amine carbamate, applied in the field of polyurethane foam, can solve the problems of unsuitable foam and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3 and 4

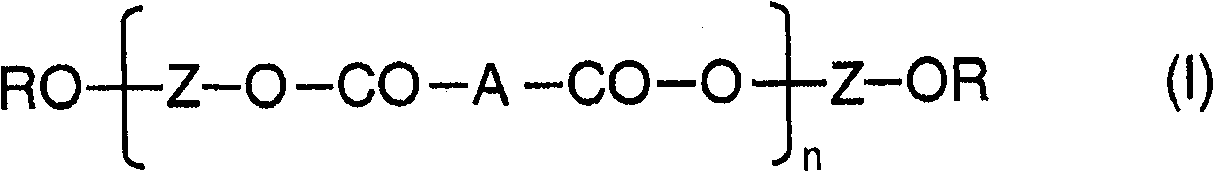

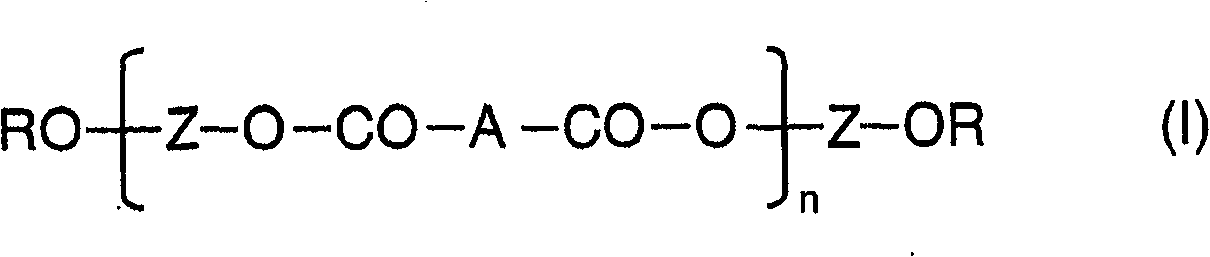

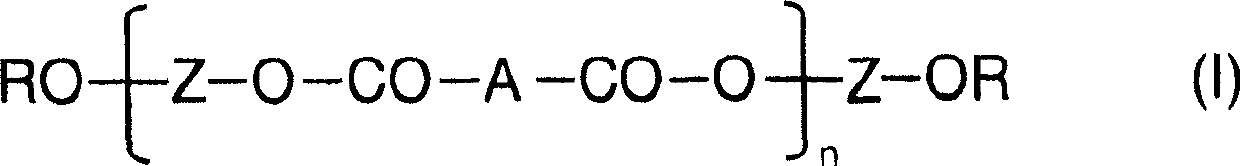

[0070] Foam pads were prepared using the same method and the same non-fugitive catalyst as Comparative Example 2, but in these examples, the aromatic diacid ester diol was added to the polyol premix. For Example 3, standard and commercially available polyester polyol (PEP, sold by Invista of Wilmington, NC under the trade name 2540 sales), while in Example 4, the same PEP was added but in a larger amount (2.0PPHP). The 2540 polyol comprises an aromatic diacid ester diol of general formula (I), derived from terephthalic acid and diethylene glycol.

[0071] table 3

[0072]

Comparative example 1 Comparative example 2 Example 3 Example 4 Catalyst component 33-LV /

BL-11 NE1070 /

NE200 NE1070 /

NE200 / PEP NE1070 /

NE200 / PEP 1 Catalyst addition

(PPHP) 0.30 / 0.10 0.19 / 0.68 0.19 / 0.68 / 1.0 0.19 / 0.68 / 2.0 Tensile strength (kPa) 175 175 169 180 50% compression set 6.37 7.04 7.30 5.06 elongation(%) 104 97 95 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com