Superfine molecular sieves filtering separating and mother solution recovering method

A technology of filtration separation and mother liquor recovery, which is applied in filtration separation, separation methods, molecular sieve compounds, etc., can solve the problems of accelerating the filtration speed of one-cross-one-bake Y-type molecular sieve aqueous slurry, not proposing a separation method, increasing production costs, etc. The effect of low equipment cost, long service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Filtration separation and mother liquor recovery of nano-beta molecular sieve slurry (all weight percentages in this description are by weight)

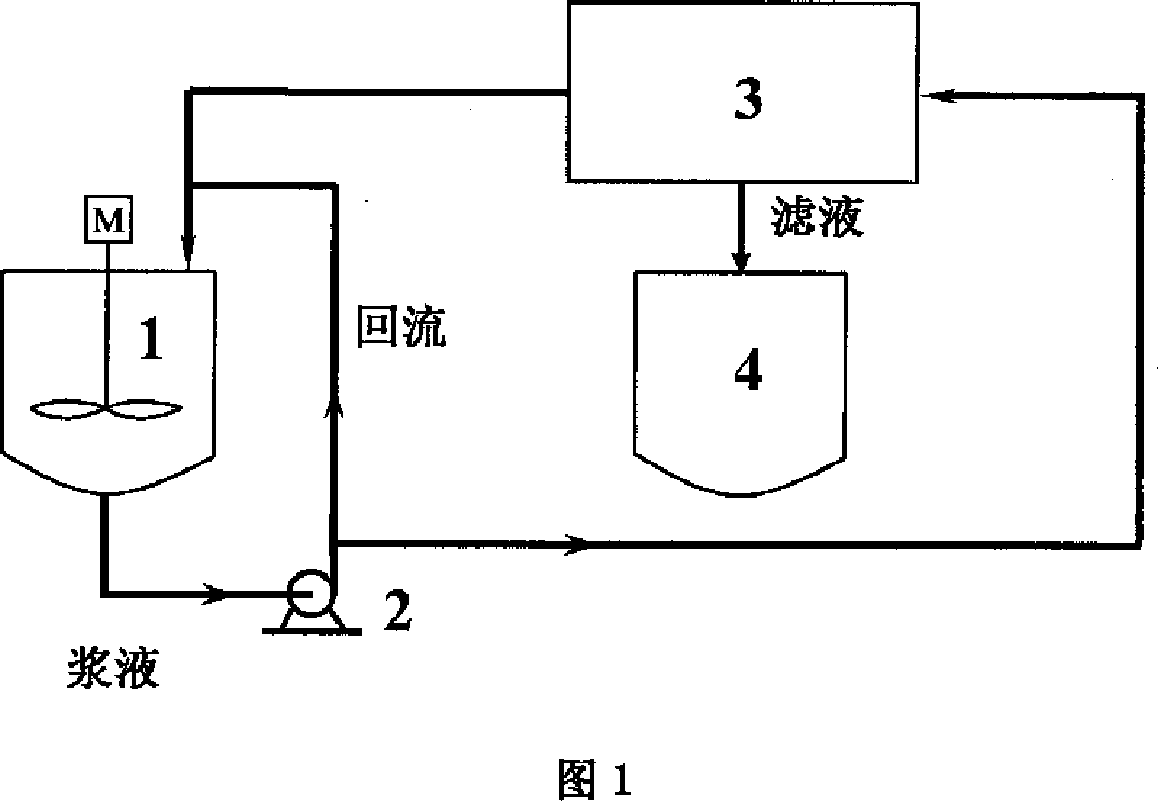

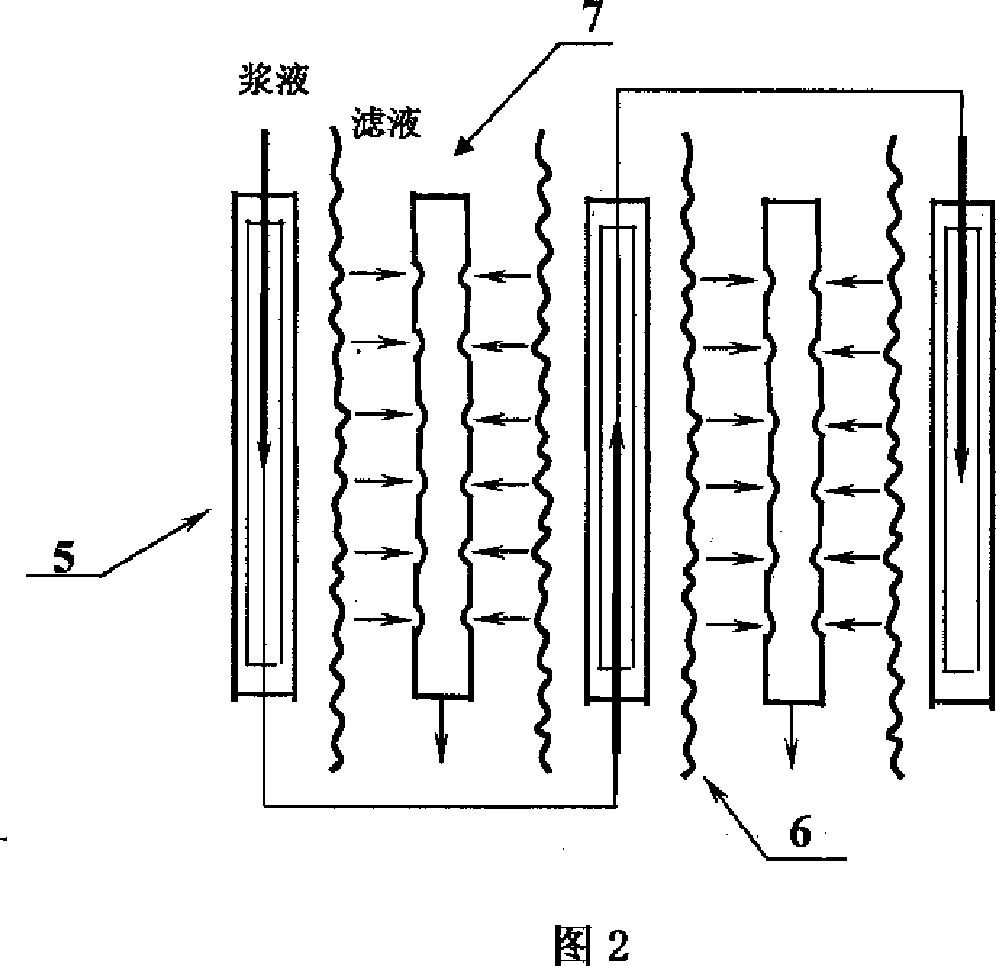

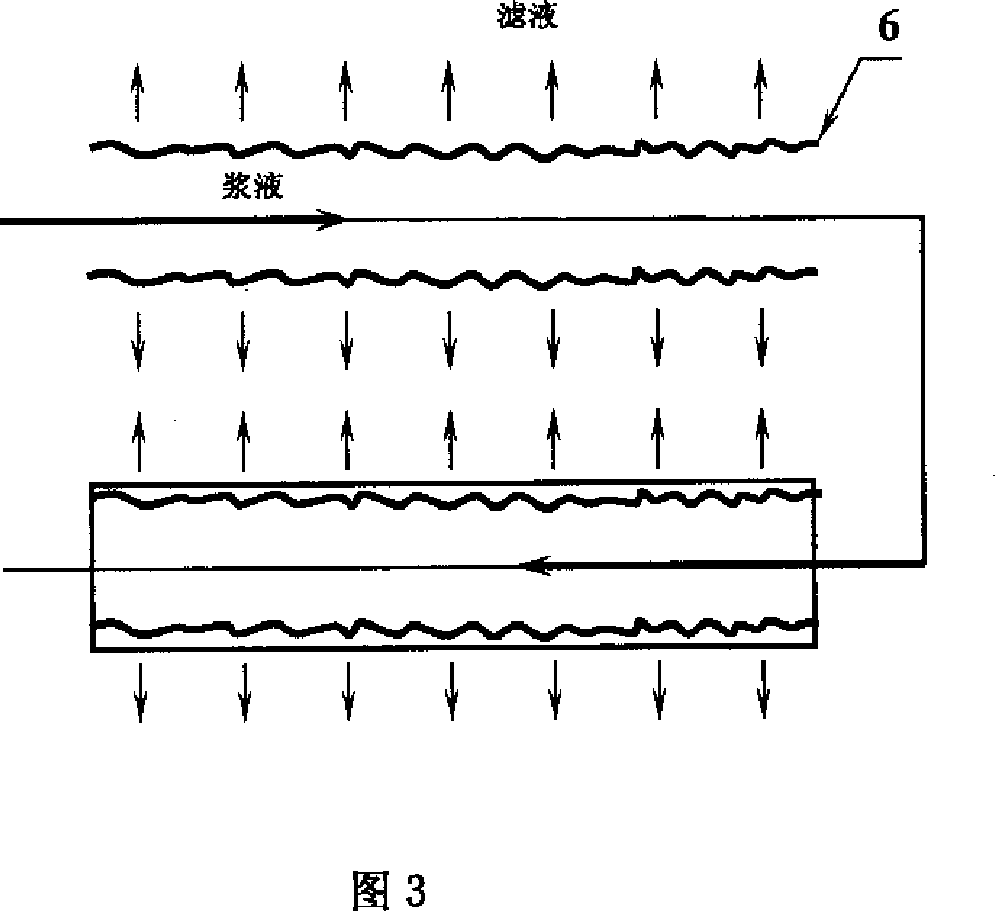

[0025] 7690 liters of nano-beta molecular sieve (Na 2 O content is 1%) slurry (d=1.30g / cm 3 ) into storage tank 1 (the material is 0Cr18Ni9Ti, 5m 3 ), use pump 2 (321 material) to transport into (flow rate is 30m 3 / h) Filtration and concentration assembly 3 performs filtration and separation, the slurry flows parallel to the filter cloth in a turbulent state, part of the mother liquor permeates out through the thin layer filter cake and filter cloth perpendicular to the filter cloth, and is collected into the filtrate collection tank to increase the concentration. The slurry is returned to the storage tank 1, so that it is concentrated to a solid content of about 42% in this way, and a total of 3200 liters of mother liquor is obtained.

[0026] When washing, add deionized water to the storage tank 1 to dilute to a solid co...

Embodiment 2

[0029] Filtration Separation and Mother Liquor Recovery of Ultrafine TiZSM-5 Molecular Sieve

[0030] 4839 liters of superfine TiZSM-5 molecular sieve crystallization slurry (d=1.24g / cm 3 ) into the enamel-lined storage tank 1 (5m 3 ), use pump 6 (tetrafluoroethylene lined pump) to transport into (flow rate is 40m 3 / h) Filtration and concentration assembly 3 performs filtration and separation, the slurry flows parallel to the filter cloth in a turbulent state, part of the mother liquor penetrates through the thin layer filter cake and filter cloth perpendicular to the filter cloth, and is collected into the filtrate collection tank to increase the concentration. The slurry is returned to the storage tank 1, and thus circulated and concentrated to a solid content of about 40%, to obtain a total of 2,500 liters of mother liquor.

[0031] When washing, add deionized water to the storage tank 1 to dilute to a solid content of about 8%, and then enter the filter concentration co...

Embodiment 3

[0034] Filtration Separation of Ultrafine ZSM-5 Molecular Sieve and Recovery of Mother Liquor

[0035] 6145 liters of ZSM-5 molecular sieve slurry (d=1.22g / cm 3 ) into storage tank 1 (the material is 316L, 5m 3 ), use pump 2 (321 material) to transport into (flow rate is 40m 3 / h) Filtration and concentration assembly 3 performs filtration and separation, the slurry flows parallel to the filter cloth in a turbulent state, part of the mother liquor permeates out through the thin layer filter cake and filter cloth perpendicular to the filter cloth, and is collected into the filtrate collection tank to increase the concentration. The slurry is returned to the storage tank 1, so that it is concentrated to a solid content of about 35% in this way, and a total of 2800 liters of mother liquor is obtained.

[0036] When washing, add deionized water to the storage tank 1 to dilute to a solid content of about 10%, and then enter the filter concentration component 3 for solid-liquid sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com