Ultrasonic extracting machine with sterilizing function

An ultrasonic and extractor technology, which is applied in the field of ultrasonic application devices, can solve the problems of large volume, few nutrients and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

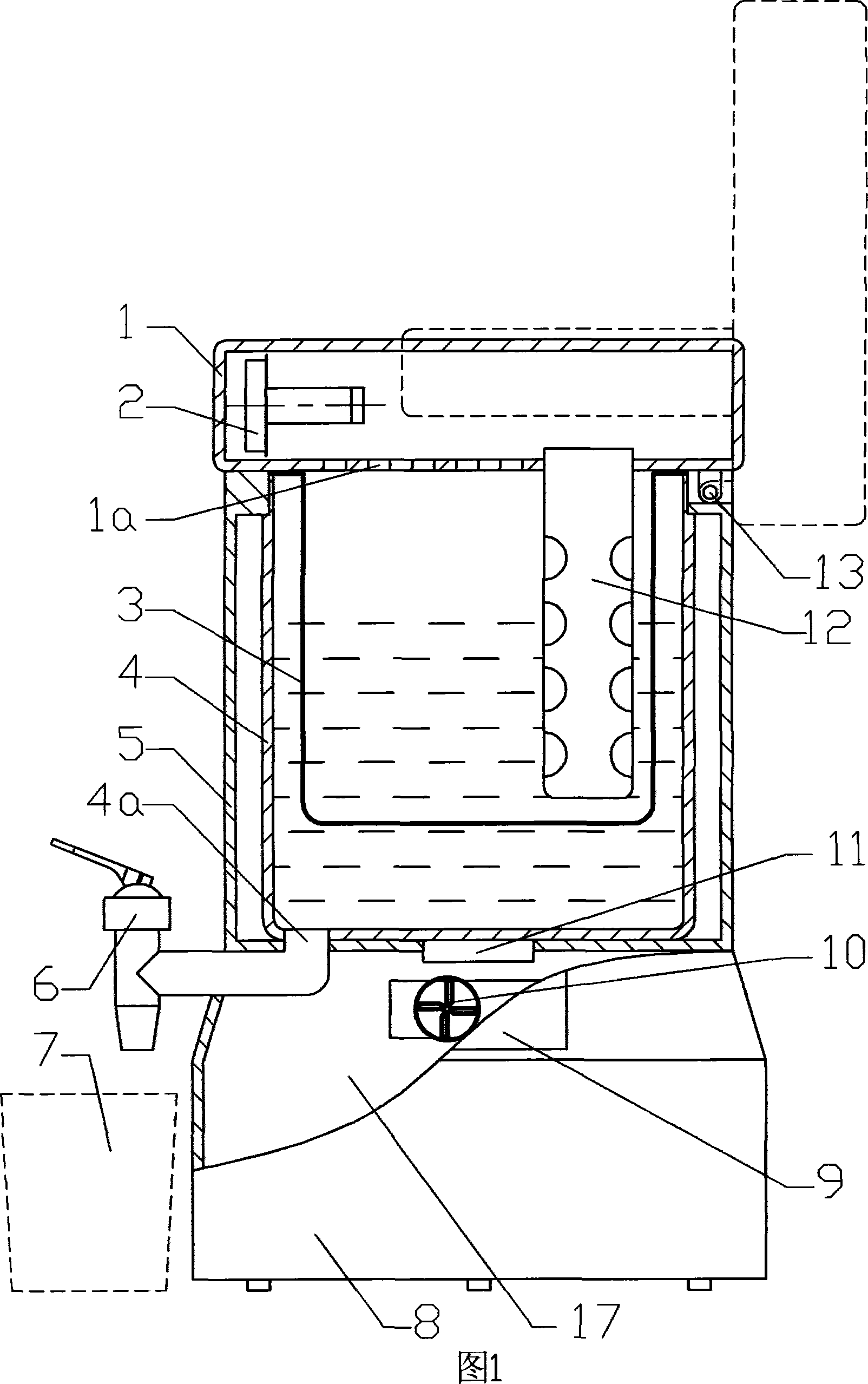

[0020] Embodiment 1 The structure of the ultrasonic extraction machine with sterilization function in this embodiment can be seen from Figure 1: it includes a base 8, an extraction tank and a sealing cover 1 connected sequentially from bottom to top, and the base 8 is provided with equipment Cavity 17, an ultrasonic transducer 12 is arranged in the extraction tank, and the extraction tank is sequentially composed of a shell 5, an inner tank 4 and a filter screen 3 from outside to inside; the ultrasonic transducer 12 is fixed on the bottom surface of the sealing cover 1, and the bottom of the sealing cover 1 The side is hinged with the extraction tank, so that after the sealing cover 1 is closed around the hinge shaft 13, the main body of the ultrasonic transducer 12 is suspended in the extraction tank.

[0021] In order to ensure the sanitation of the solute before extraction, a sterilizing device is provided in the sealing cover 1, which can be sterilized by RGF photohydrogen ...

Embodiment 2

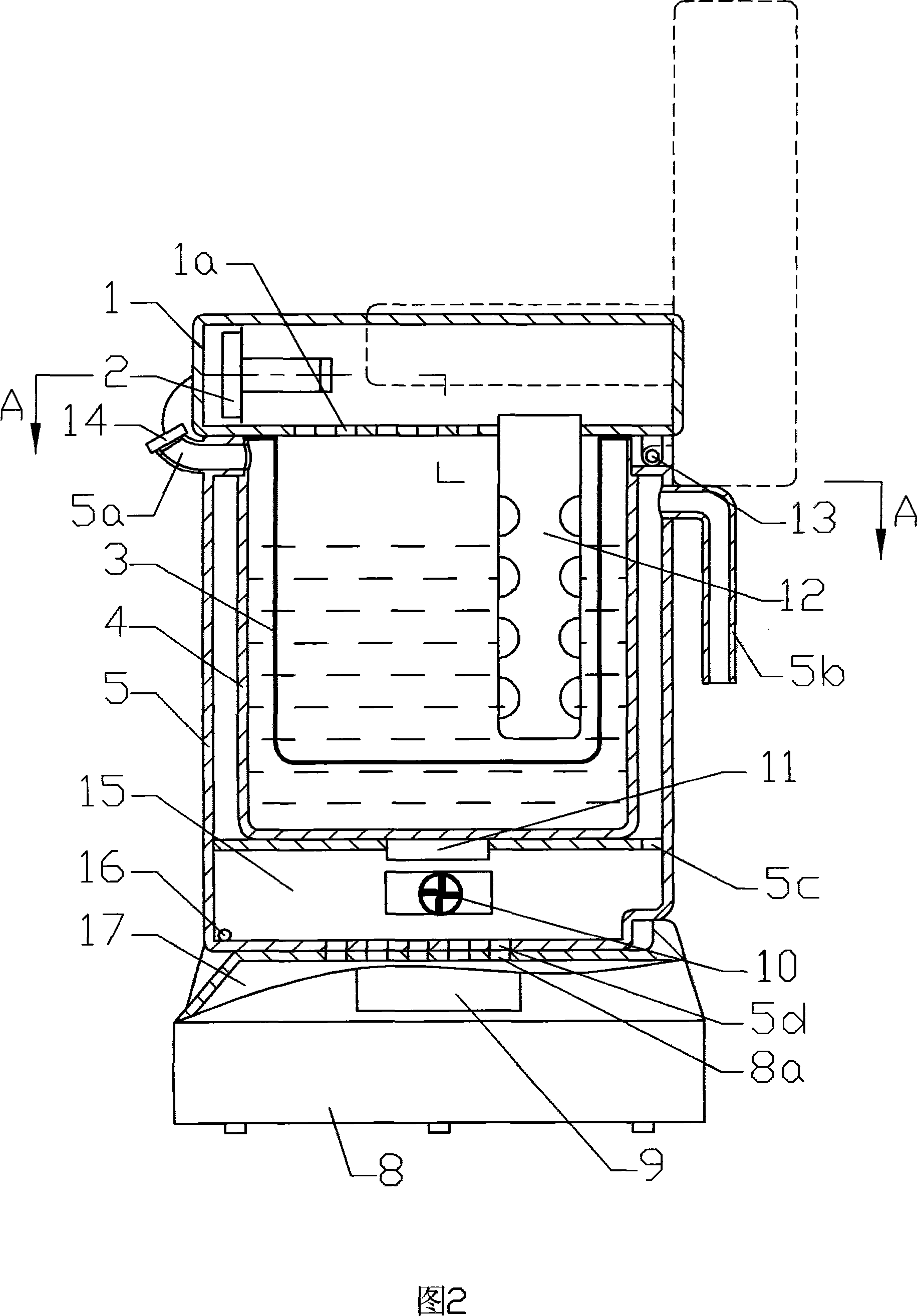

[0027] Embodiment 2 The structure of the ultrasonic extraction machine with sterilization function in this embodiment can be seen from Figure 2. It is different from Embodiment 1 in that: an extraction liquid outlet is arranged on the upper part of the extraction tank, and there is an outlet at the outlet. A pouring spout 5b with a tenon 14, and a handle 5b is installed on the wall of the shell 5 corresponding to the other side of the extraction liquid outlet. To achieve pouring, it is necessary to hinge the bottom side of the extraction tank with the side of the base 8 through the hinge shaft 16 so that the extraction tank can rotate around the hinge shaft 16 smoothly.

[0028] When sterilizing before the extraction, the tenon 14 is used to cover the pouring spout 5b, so that the sterilizing gas will not leak out in the extraction tank and affect the sterilizing effect.

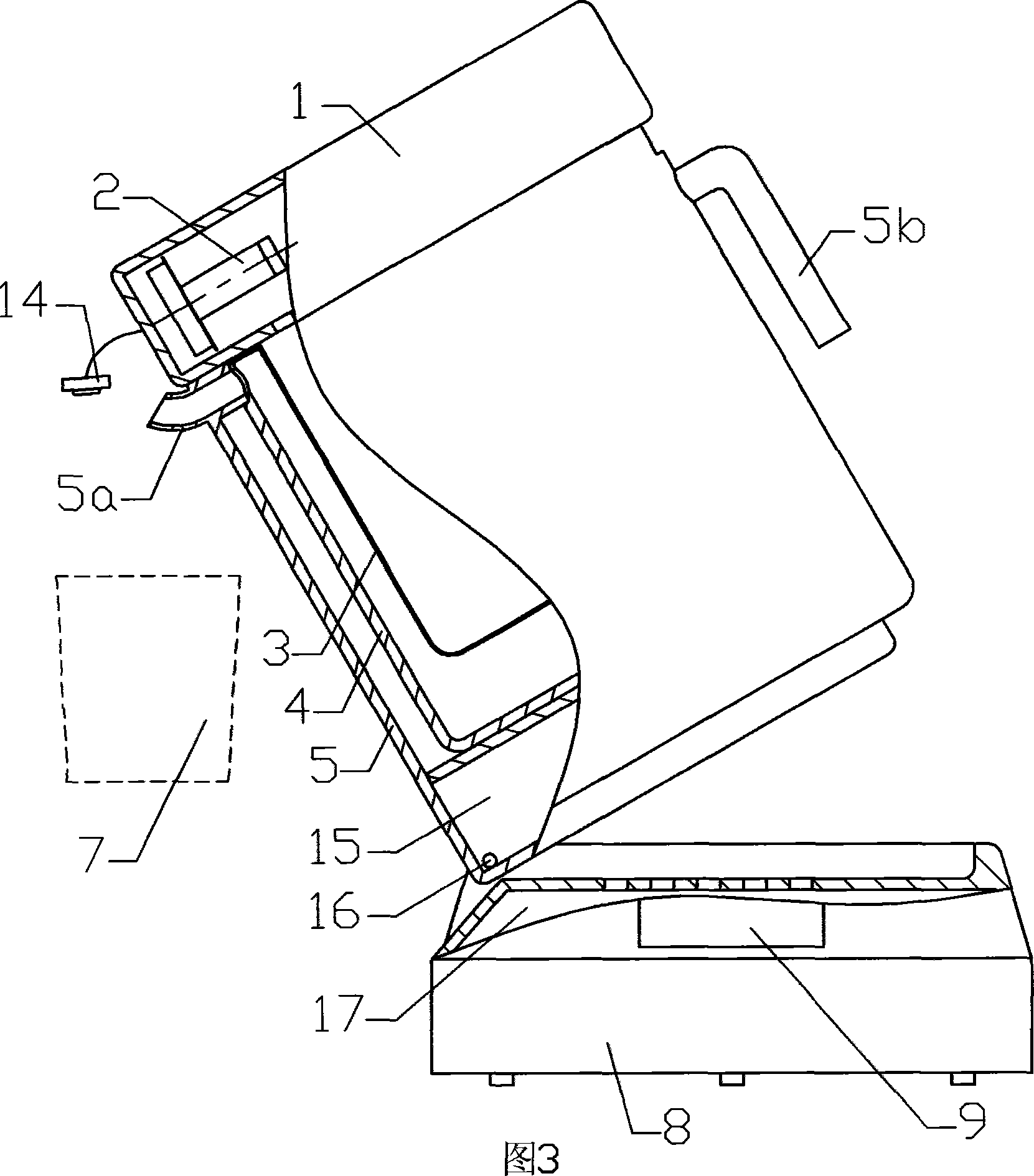

[0029] When the extraction is finished, hold the handle 5b, as shown in Figure 3, take out the tenon 14, ...

Embodiment 3

[0032]Embodiment 3 The structure of the ultrasonic extraction machine with sterilization function in this embodiment can be seen from Figure 5. It is different from Embodiment 1 or 2 in that: an outlet for extracting liquid is arranged on the upper part of the extraction tank, and at the outlet A siphon 20 is installed, one end of the siphon 20 is inserted into the bottom of the liner 4, the other end is suspended outside the extraction tank to become the outlet of the extract, and a sealing ring tenon 19 is adorned in a hole at the top of the siphon 20. When the extraction is over, put the cup under the outlet of the extraction solution of the siphon tube 20, hold the handle 5b, rotate the extraction tank around the hinge shaft 16, and the internal liquid will continuously flow out into the cup 7 due to the siphon effect, even if the extraction tank It also does not stop after returning to a horizontal position. Only after the tenon 19 is pulled out by pulling the ring to all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com