Megawatt direct driving type wind and electric joint-net current transformer

A direct-drive, converter technology, applied in wind power generation, conversion equipment for intermediate conversion to DC, conversion of AC power input to AC power output, etc., can solve the constraints of wind power industrialization process, megawatt-level variable speed Constant-frequency wind power electronic control equipment power converters rely on foreign imports and other issues to achieve the effects of improving competitiveness, high power levels, and realizing power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in more detail:

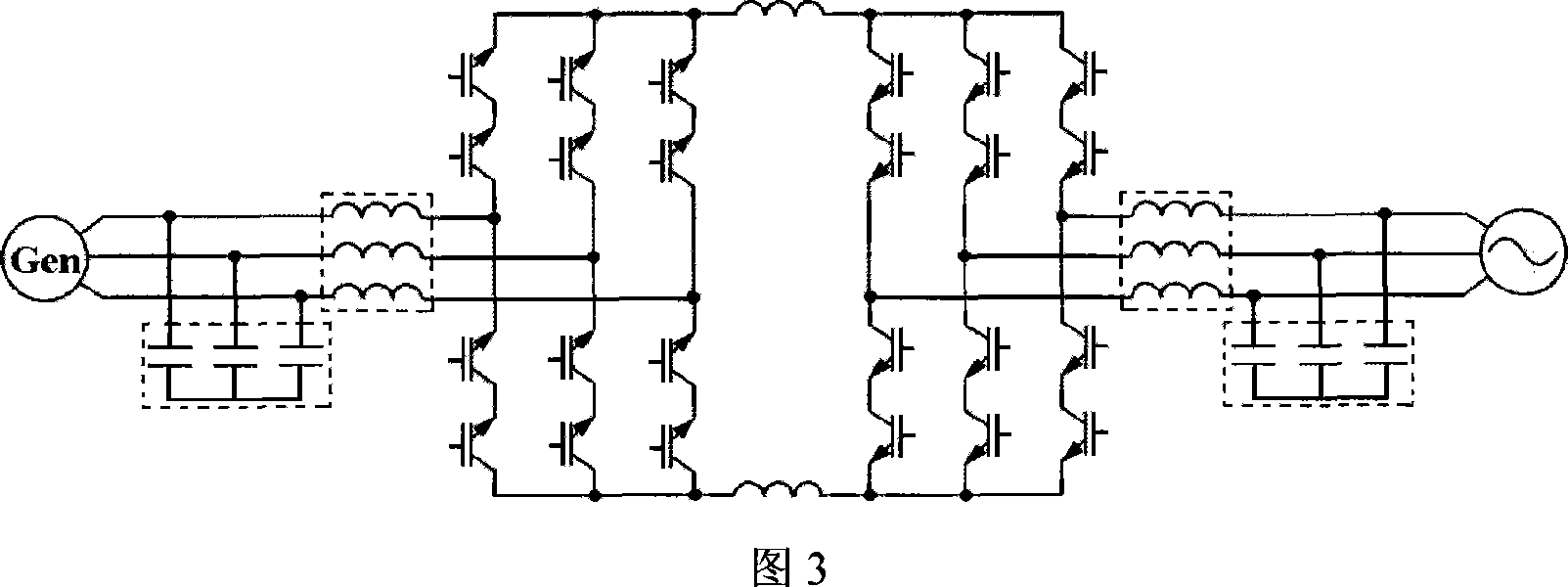

[0025] With reference to Fig. 4, this embodiment includes: a wind power generator with a megawatt power level, a three-phase filter capacitor C on the generator side f1 , rectifier unit, step-up chopper unit, inverter unit, grid-side three-phase filter capacitor C f2 、C f3 , transformers and power frequency grids. The rectifier unit is composed of a three-phase uncontrolled diode rectifier, which includes six diodes (D 1 ~D 6 ). The boost chopper unit is formed by multiple boost choppers, and each boost chopper is composed of a DC side filter capacitor C 1 , inductance L 1 , switch tube T 1 , Diode D 7 and DC side support capacitor C 2 and C 3 constitute. The inverter unit is composed of two or more three-phase fully-controlled inverters connected in parallel, and each inverter is composed of six switching tubes (T 11 ~T 16 , T 21 ~T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com