Diaphragm pump of constant pressure type

A diaphragm pump and diaphragm valve technology, applied in the direction of pump, pump control, liquid variable capacity machinery, etc., can solve the problems of wasting water resources, inconvenience, and more reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

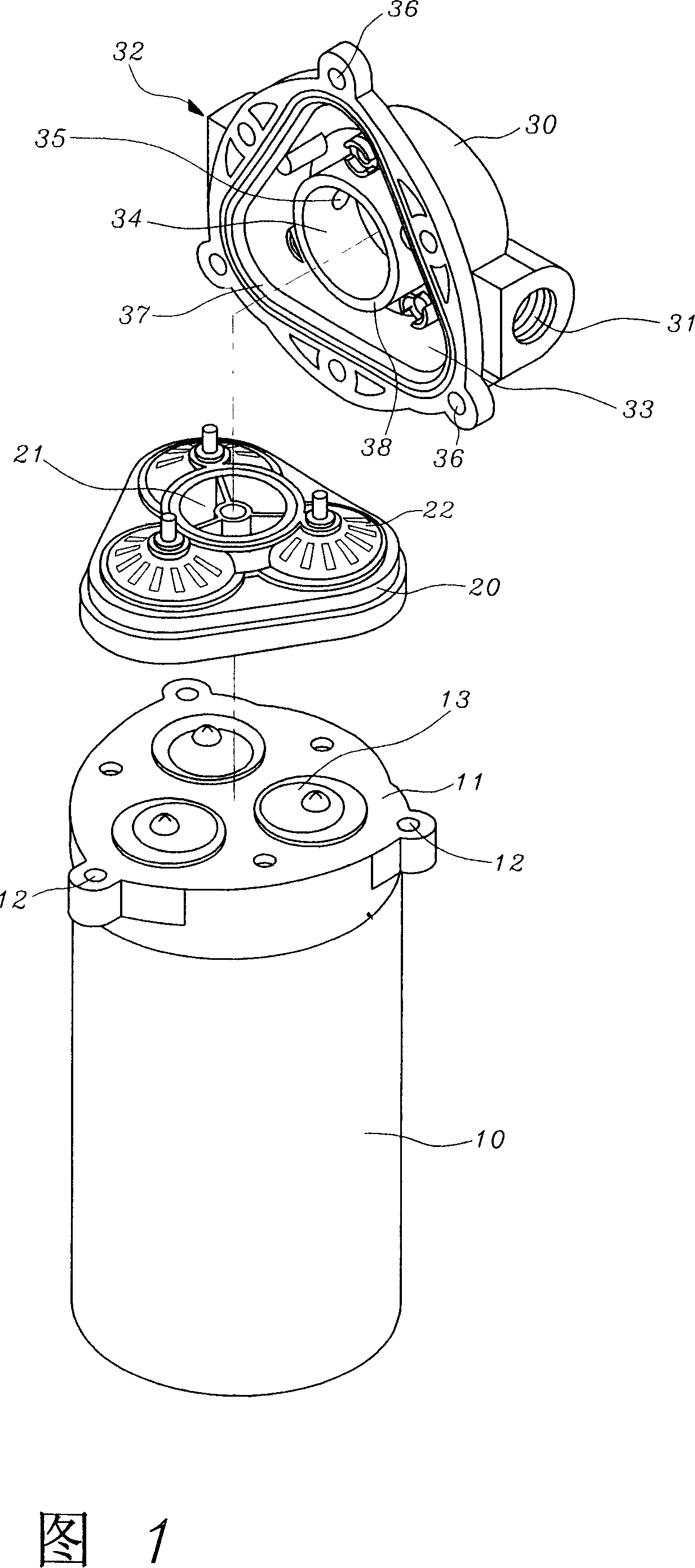

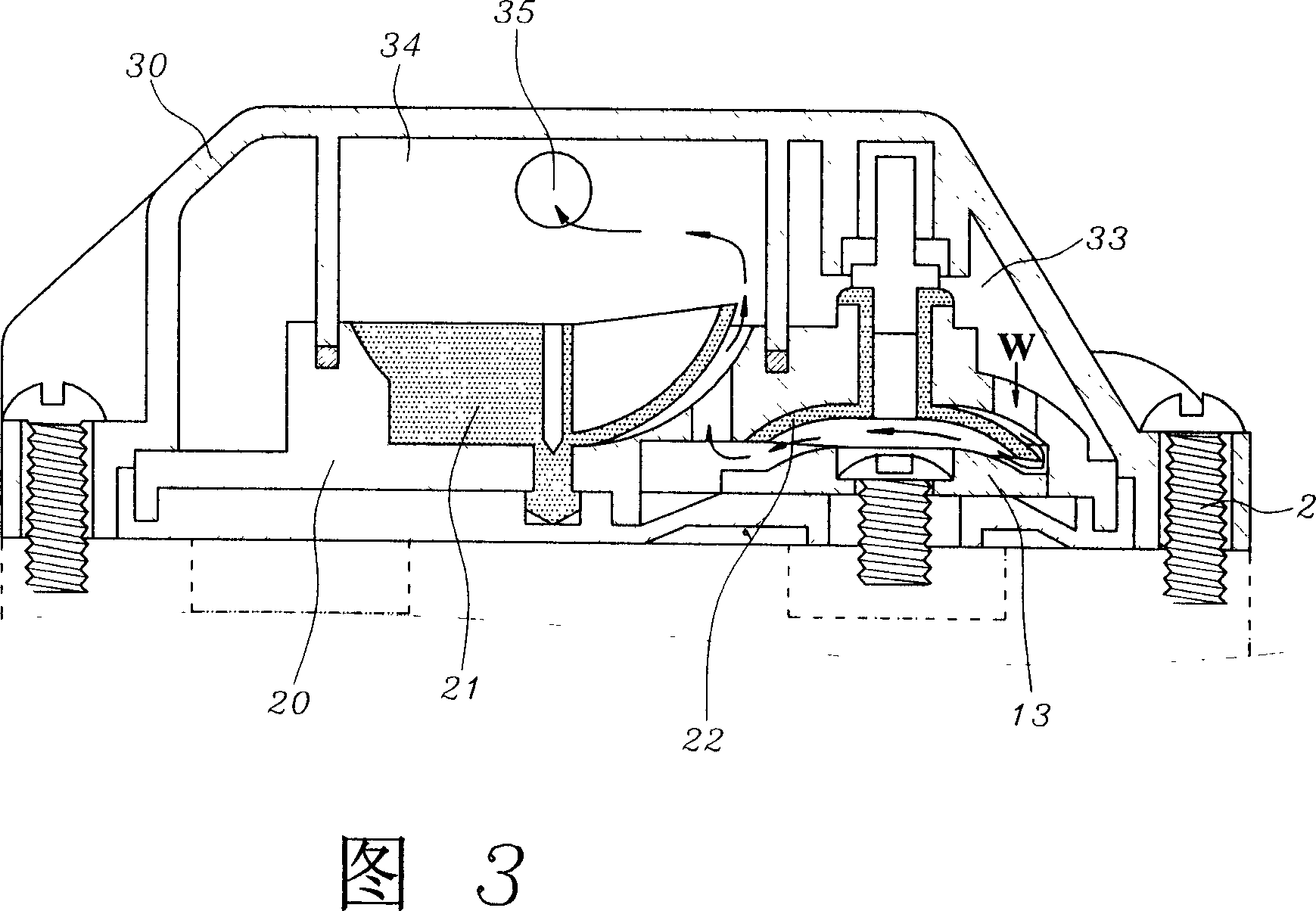

[0075] As shown in Figures 15 to 21, it is the first embodiment of the constant pressure diaphragm pump of the present invention. A constant pressure diaphragm pump of the present invention includes: a motor 10; (Not shown) the upper cover base 11 at the end, the upper cover base 11 is provided with a number of screw holes 12 on its periphery; one is pivoted in the upper cover base body 11, and is driven by the output shaft of the motor 10 and converted into an axial direction A number of reciprocating balance wheels 13; a diaphragm valve cover group 20 arranged on the upper cover seat 11, a high-pressure valve 23 is embedded in the center of the top surface, and a surrounding bottom surface of the high-pressure valve 23 is embedded There are several low-pressure valves 22; and a pump head cover 70, etc.; through the several screw holes 12 of the upper cover base 11 and the preset perforations 701 corresponding to the pump head cover 70, they are screwed together by bolts 2 Into o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com