Washing machine drier with condenser set in waste water collecting tank

A washing-drying machine and waste water collection technology, applied in the field of washing machines, can solve the problems of complicated condenser design, long drying time, low cooling efficiency, etc., and achieve the effects of simplifying design, saving cooling water, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

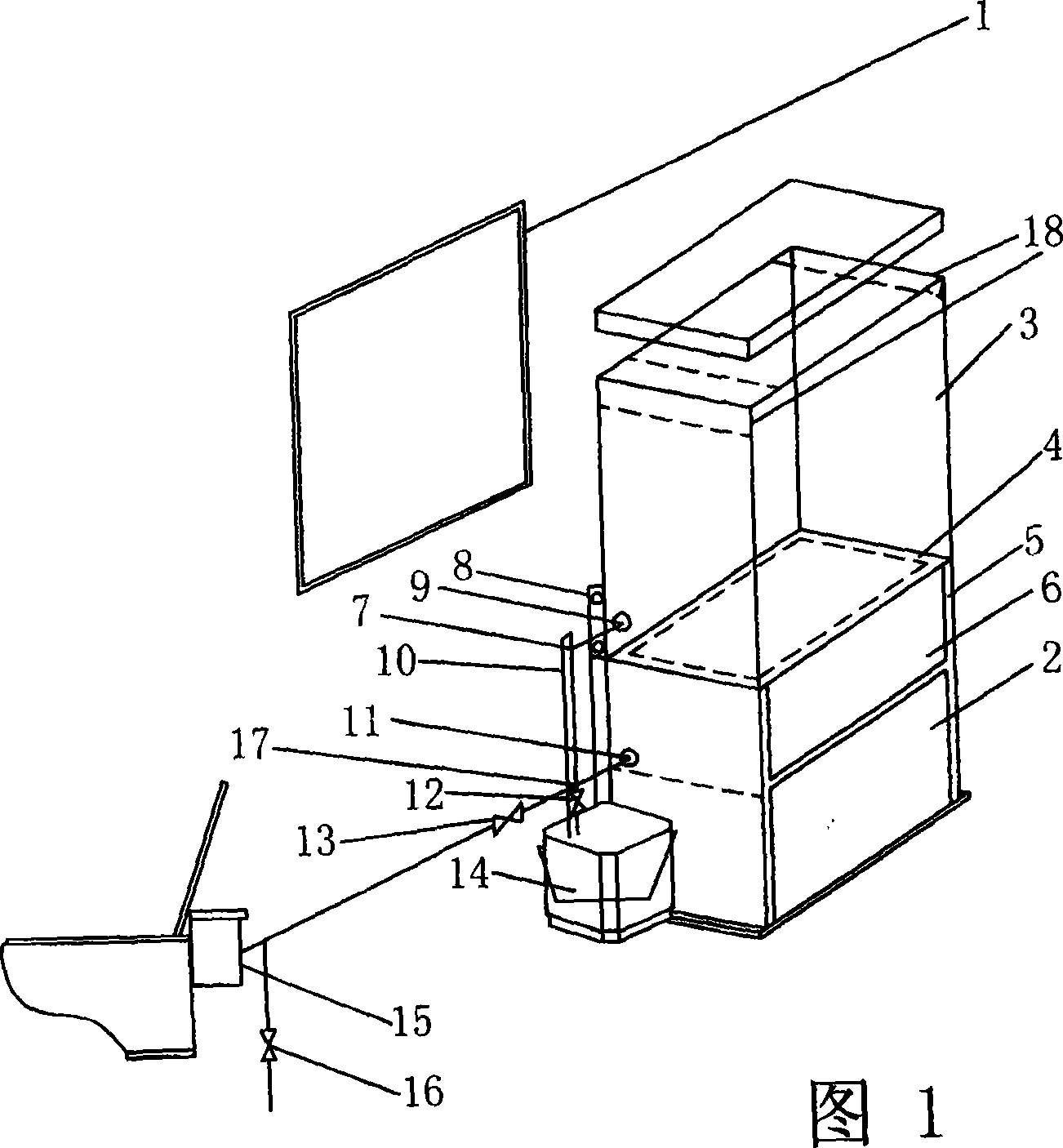

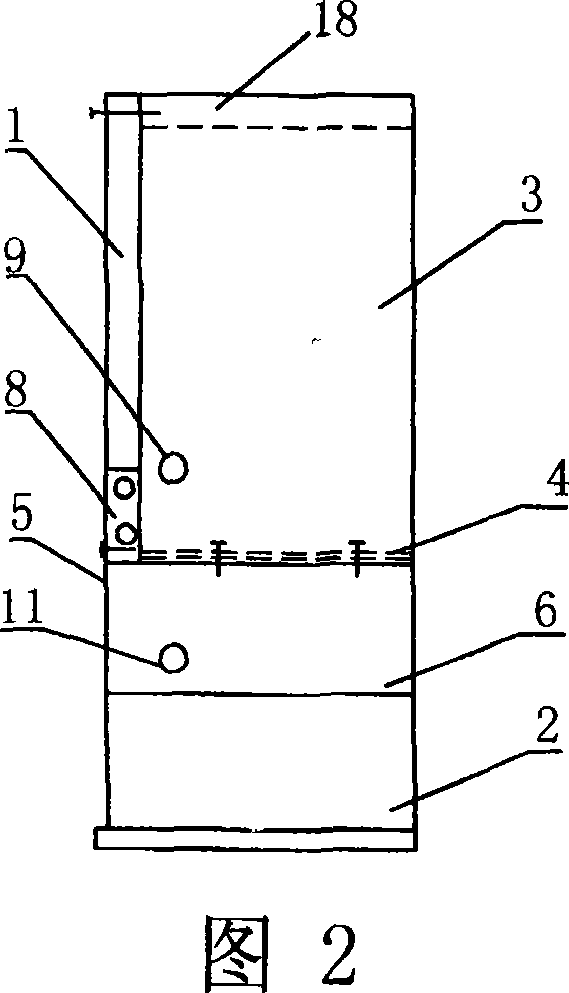

[0034] As shown in Figure 1, Figure 2, and Figure 3, the installation steps are as follows:

[0035] a, use bolts to fix the strong bracket 1 and the four inner threaded sleeves exposed at the four corners of the back of the drum washing machine 3 .

[0036] b. Place the drum washing machine on the top of the box-type base 5 covered with anti-shock rubber pads, and adjust the levelness of the washing machine. Use nuts to be located at the bolt on the top of the box-type base 5, and the bottom surface of the drum washing machine 3 is fixedly connected with the frame 4, and the frame 4 is firmly combined with the shock absorber of the washing bucket.

[0037] c, fasten the vertical fixing plate 8 located at the top two corners of the box-type base 5 and the strong bracket 1 behind the drum washing machine with bolts.

[0038] d. Put the condenser 21 into the waste water collection tank 6, or install it on the bottom surface or the side of the waste water collection tank 6, conn...

specific Embodiment 2

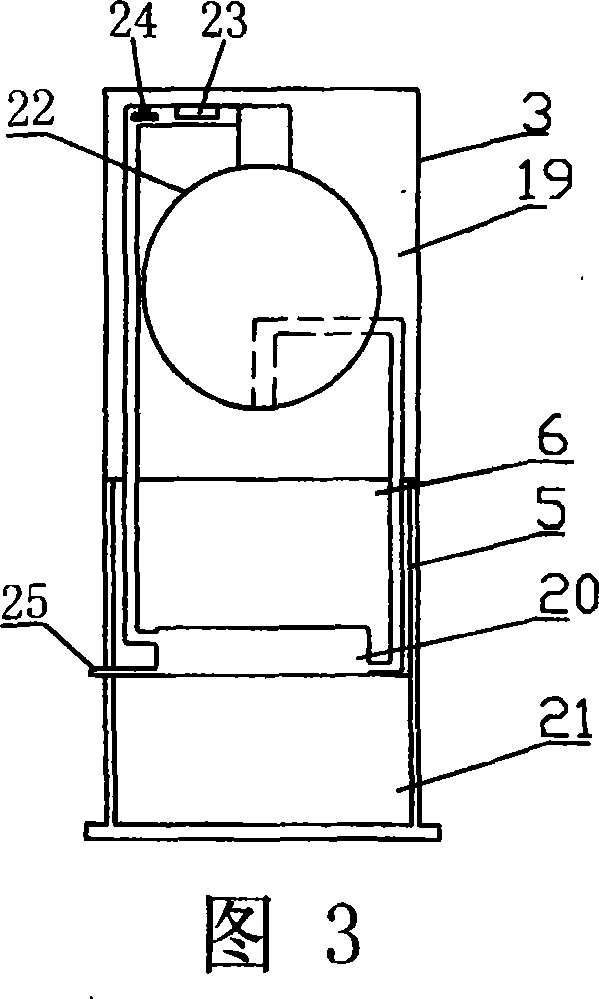

[0043] As shown in Fig. 1, Fig. 2, shown in Fig. 4: utilize the space below waste water collection box 6, remove wardrobe 21, a clothes drying box 2 is set, make it with circulation fan 24, drying heater 23, the laundry of drum washing machine The outer tub 22, the condenser 20, and the circulating air duct 19 are connected to form a circulating air channel. After the clothes are dehydrated and dried, they are classified according to thickness: take out thicker clothes such as jeans, put them on a flat plate, flatten them with a cold iron, fold them, hang them on the hangers, and put them into the drying box 2, and leave the thinner clothes in the laundry In this way, one is to separate the laundry so that it does not overlap, and the other is to avoid wrinkles on thicker clothes. Start the drying system, the clothes can be dried evenly and quickly, and the thicker clothes in the drying box are directly dried and shaped without ironing, saving time and energy. The circulation...

specific Embodiment 3

[0044] As shown in Figure 1, Figure 2, and Figure 5: the clothes drying box 2 is connected with the circulation fan 24, the drying heater 23, the condenser 20, and the circulation air pipe 19 to form a circulation air duct, so that the hot air does not enter the washing machine. The type is that there is no drying system in the washing machine, but a drying box is set up in addition below, and the condenser 20 utilizes the waste water collection box 6 to dissipate heat. This design makes the heat of the heater only used in the drying box, instead of heating the two stainless steel washing tubs, and can selectively dry the necessary clothes, saving energy efficiently and quickly.

[0045] The invention raises the position of the front-opening type drum washing machine, which is just suitable for most adults and does not need to squat and bend over to do laundry. The operating keyboard on the front of the drum washing machine can be arranged under the clothes opening or at a mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com