Sulfur resisting transform technique under low water / gas for gasifying powdered coal

A sulfur-resistant shift and process technology, which is applied to the sulfur-resistant shift process field of the first reactor, can solve the problems of heat not being taken out in time, high degree of methanation side reactions, low space velocity, etc., and achieves the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

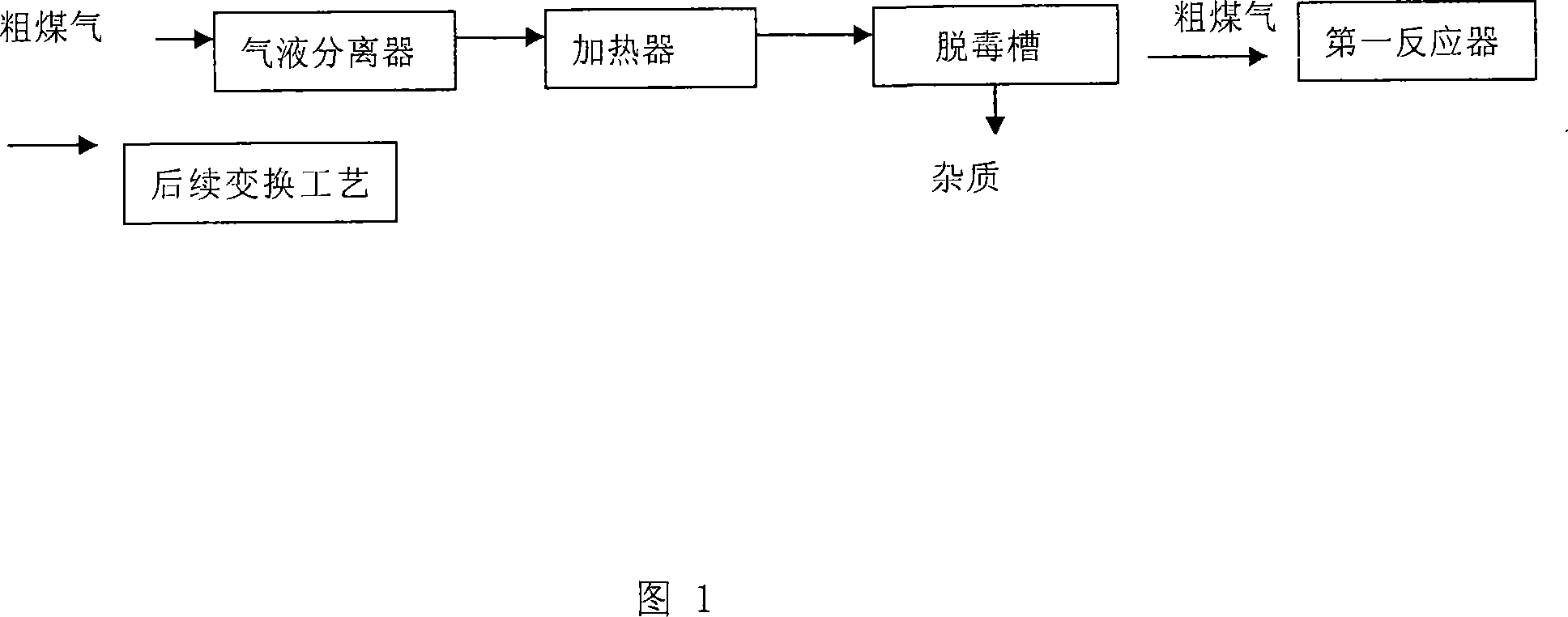

Embodiment 1

[0026] The crude gas from the "Shell" pulverized coal gasification process directly enters the gas-liquid separator, and the crude gas coming out of the top of the separator is heated to 190°C, enters the detoxification tank to remove impurities, and then enters the first reactor for shift reaction , the volume content of dry basis CO in the raw gas entering the first reactor inlet is 61%, the first reactor inlet temperature is 190°C, the water / gas volume is 0.15, and the space velocity is 6000h -1 , the reaction pressure is 3.0MPa, the hot spot temperature of the first reactor bed is 330°C, the shift gas CO content from one section is 45% relative to the dry basis, and enters the subsequent section for the shift reaction, and finally becomes a reaction by-product The amount of methane emitted is 0.01% by volume on a dry basis.

Embodiment 2

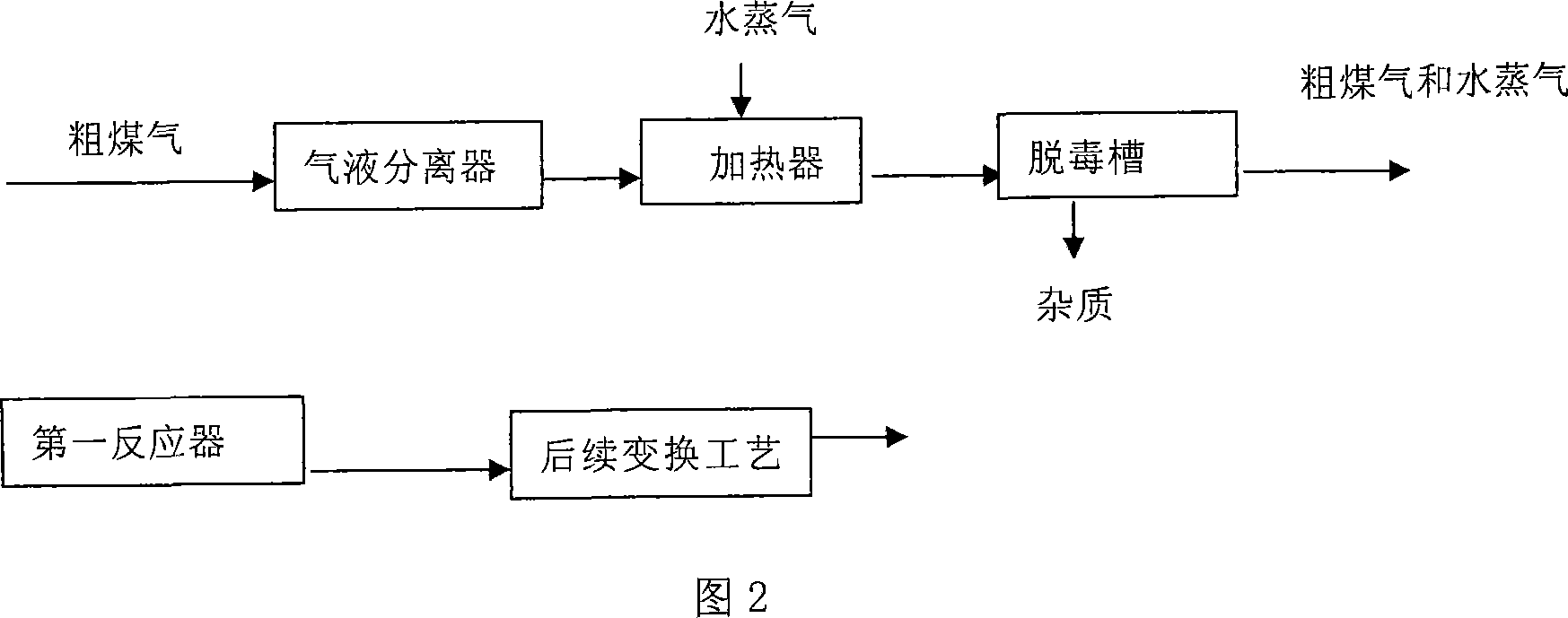

[0028] The crude gas from the "Shell" pulverized coal gasification process directly enters the gas-liquid separator, and the crude gas and water vapor from the top of the separator are heated together to 200°C, enter the detoxification tank to remove impurities, and then enter the first reaction In the first reactor, the volume content of CO on a dry basis in the crude gas entering the first reactor inlet is 63%, the first reactor inlet temperature is 200°C, the water / gas volume ratio is 0.20, and the space velocity is 7000h -1, the reaction pressure is 3.6MPa, the hot spot temperature of the first reactor bed is 380°C, and the shift gas CO content from one section is 40% relative to the dry basis, and enters the subsequent section for the shift reaction, and finally becomes a reaction by-product The amount of methane emitted is 0.3% by volume on a dry basis.

Embodiment 3

[0030] The crude gas from the "Shell" pulverized coal gasification process directly enters the gas-liquid separator. The crude gas from the top of the separator and the water vapor from the medium-pressure boiler are heated together to 190°C and enter the detoxification tank to remove impurities. , into the first reactor for shift reaction, wherein the dry base CO volume content in the crude gas entering the first reactor inlet is 69%, the water / gas volume ratio is 0.18, the first reactor inlet temperature is 190°C, and the water gas The volume ratio is 0.20, the space speed is 7000h -1 , the reaction pressure is 3.6MPa, the hot spot temperature of the first reactor bed is 355°C, and the shift gas CO content from one section is 50% relative to the dry basis, and enters the subsequent section for the shift reaction, and finally becomes a reaction by-product The emission of methane is 0.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com