Technique for molding new type proton exchange membrane

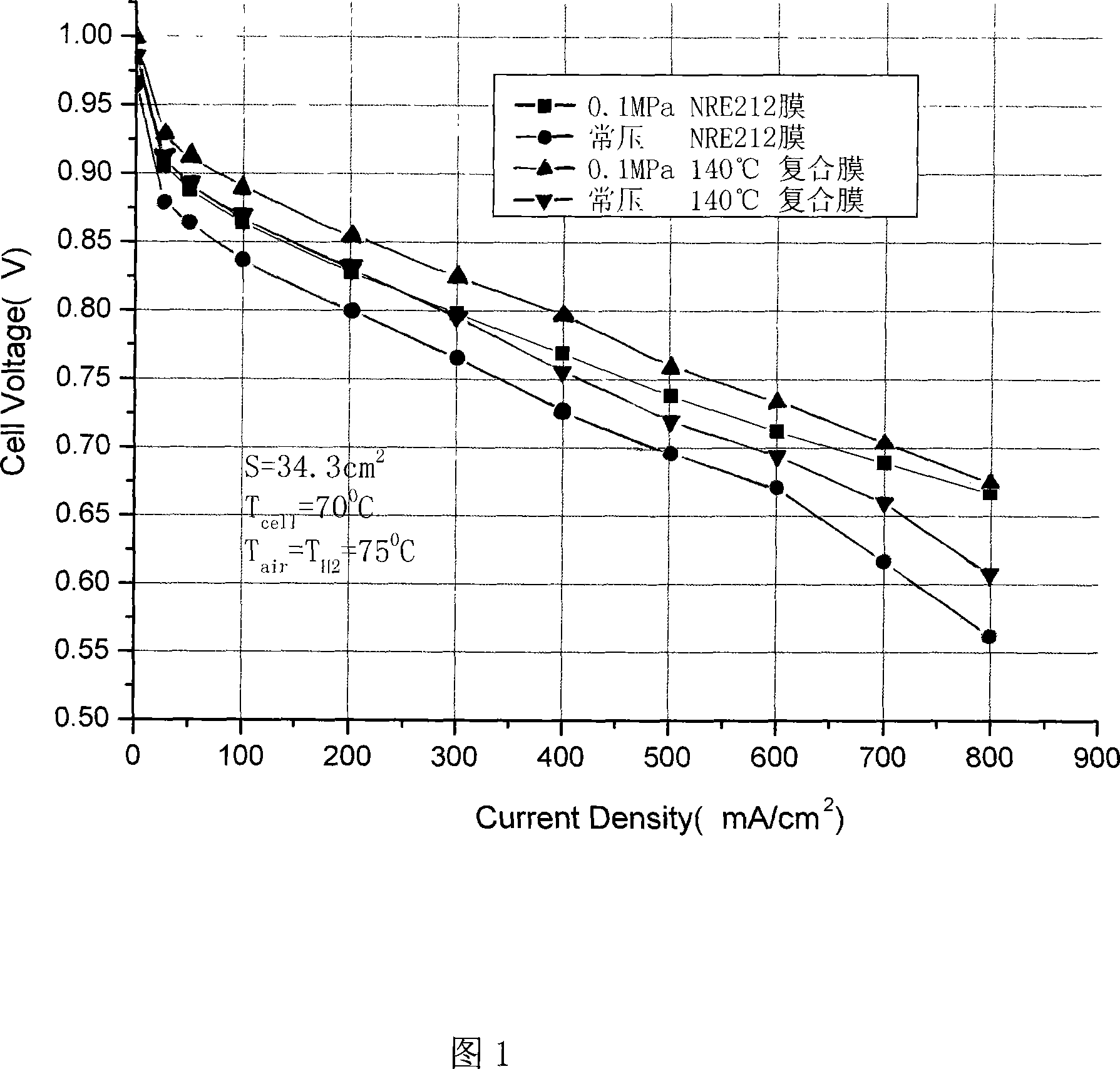

A technology of proton exchange membrane and forming process, which is applied in the field of proton exchange membrane batteries, can solve the problems of difficult-to-area composite membranes and difficult-to-mass production of composite membranes, and achieve simple process routes, facilitate large-scale production, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A mixed solvent of ethanol and water was used to heat and dissolve the waste ion exchange membrane (EW=1100) of the chlor-alkali industry in an autoclave to prepare a 5% perfluorosulfonic acid solution. Using the difference in boiling point, replace other organic alcohol solvents in the prepared 5% perfluorosulfonic acid resin solution with n-propanol solvent, and divide the perfluorosulfonic acid resin solution into two contents of 1% and 5% in the agent replacement According to the ratio of Nafion resin: dimethyl sulfoxide = 1: 1, dimethyl sulfoxide was added to the resin solution of perfluorosulfonic acid, shaken, and set aside. The expanded polytetrafluoroethylene microporous film with a pore size of 0.01 μm to 1.0 μm, a porosity greater than 80%, and a thickness of 10 to 40 μm is selected as the base membrane. After removing the organic matter on the surface of the expanded polytetrafluoroethylene microporous film, it is placed on the film forming machine, and the ...

Embodiment 2

[0030] A mixed solvent of ethanol and water was used to heat and dissolve the waste ion exchange membrane (EW=1100) of the chlor-alkali industry in an autoclave to prepare a 5% perfluorosulfonic acid solution. Using the difference in boiling point, replace other organic alcohol solvents in the prepared 5% perfluorosulfonic acid resin solution with n-propanol solvent, and divide the perfluorosulfonic acid resin solution into two contents of 2% and 5% in the solvent replacement The resin solution of perfluorosulfonic acid, Nafion resin: dimethyl sulfoxide = 1: 3, after adding dimethyl sulfoxide, the film forming process of the device is: the expanded polytetrafluoroethylene micropore is dragged by the film forming machine The film runs on the carrying roller of the film forming machine. The base film is first immersed in a perfluorosulfonic acid resin solution with a concentration of 2%, and dried in a drying oven at 70°C for 8 minutes, so that the internal pores of the base film...

Embodiment 3

[0032]A mixed solvent of n-propanol and water was used to heat and dissolve the chlor-alkali industrial waste ion exchange membrane (EW=1100) in an autoclave to prepare an 8% perfluorosulfonic acid solution. And wherein part of the solution is diluted to 1%, according to Nafion resin: dimethyl sulfoxide=1: 2 ratio, add dimethyl sulfoxide, Nafion resin: silicon dioxide=1: 0.03 ratio, add silica sol, Shake and set aside. The expanded polytetrafluoroethylene microporous film is dragged by the film-forming machine to run on the carrying roller of the film-forming machine. The base film is first immersed in a perfluorosulfonic acid resin solution with a concentration of 1%, and dried in a drying oven at 65°C Dry in the middle for 9 minutes, so that the internal pores of the base film are completely closed, and the dried base film continues to be immersed in a solution with a solution concentration of 8%, and dried in a drying oven at 65°C for 11 minutes, and has been kept at 5% sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com