Light guide plate and method for producing same

A light guide plate and substrate technology, applied in optics, light guides, light sources, etc., can solve problems such as cumbersome procedures and achieve good brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

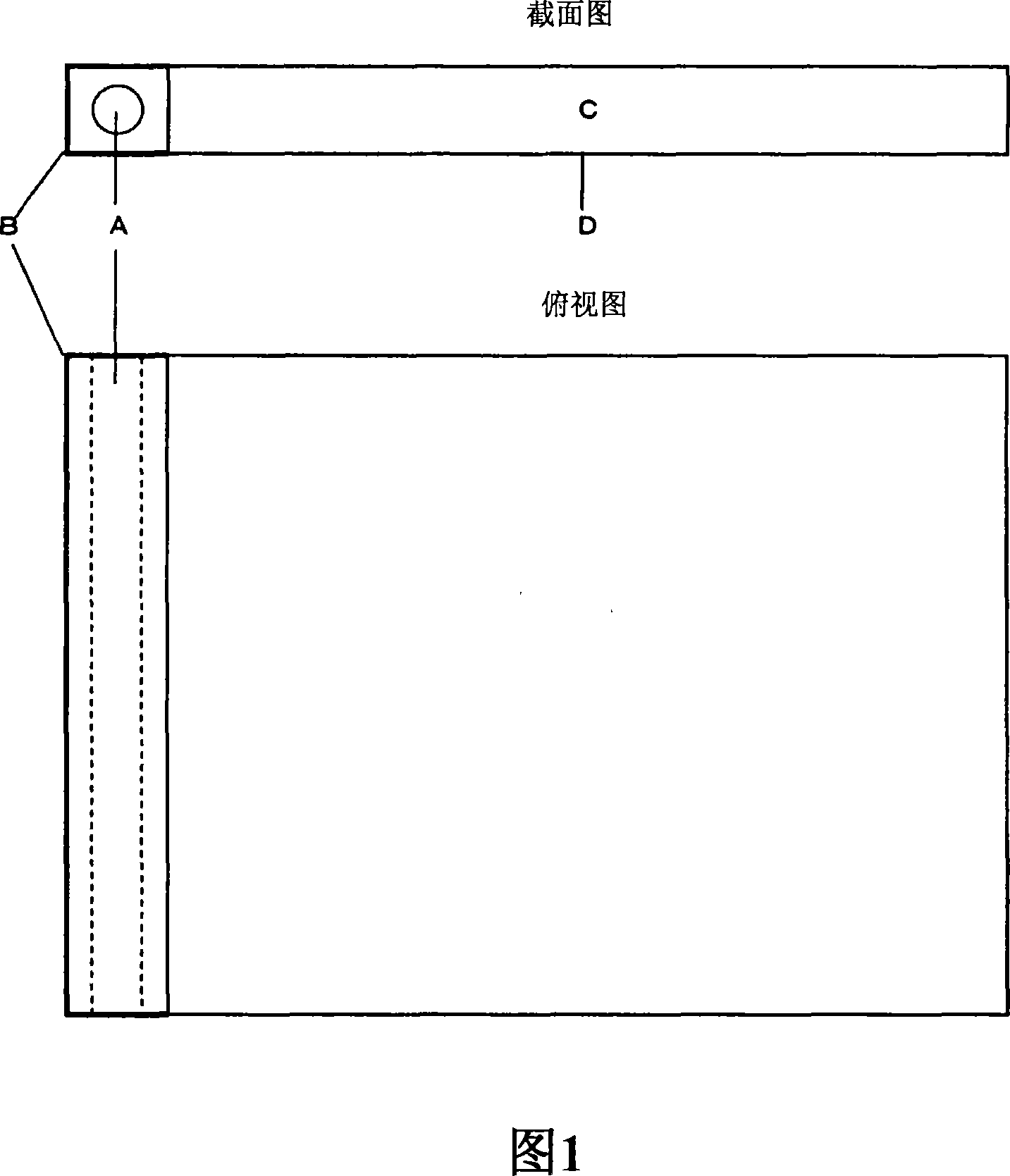

[0060] The methacrylic resin polymer-A is adjusted to 5% of the extruded raw material through the content of the sieve nominal size being less than 150, using a 150mmφ single-screw extruder (machine Cylinder temperature: 200°C-210°C-210°C-260°C-260°C-240°C from the feed side) and three polished rollers after temperature adjustment (roller temperature: 80°C) and traction device A plate forming machine uses a 200-mesh screen made of SUS304 between the barrel and the die to obtain a methacrylic resin extruded plate (extruded plate-A1) with an extrusion rate of 600Kg / hr, a width of 1000mm, and a thickness of 6mm. Table 1 shows the results of measuring bright spots using the bright spot measuring device shown in FIG. 1 . Next, cut out a size of 241 mm in width and 319 mm in length from the obtained extruded board with a circular saw, and polish the cut surface of the cut board with a precision grinder (PLA-BEAUTY: manufactured by Megalo Technica Co., Ltd.), and further perform surf...

Embodiment 2

[0064] Except that the amount of methacrylic resin polymer-B passed through the wire mesh with a nominal size of 14 mesh is adjusted to 0.1% as the extruded raw material, the extruded sheet is formed in the same manner as in Example 1 to obtain the extruded sheet- C1. The same measurement as in Example 1 was performed, and the results obtained are shown in Table 1.

Embodiment 3 and 4

[0068] Using the extrusion raw materials of Comparative Examples 1 and 2, except that the 400-mesh screen made of SUS304 was used to replace the 200-mesh screen between the barrel and the die, the extruded sheet was formed in the same way as in Example 1 to obtain the extruded sheet- E1, F1. The same measurement as in Example 1 was performed, and the results obtained are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com