Grey fabric flaw detecting instrument

A defect detection and textile technology, applied in the field of photoelectric measurement and testing instruments, can solve problems such as low detection efficiency, low detection quality, and high labor intensity, and achieve the effects of reducing labor intensity, simple structure, and significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

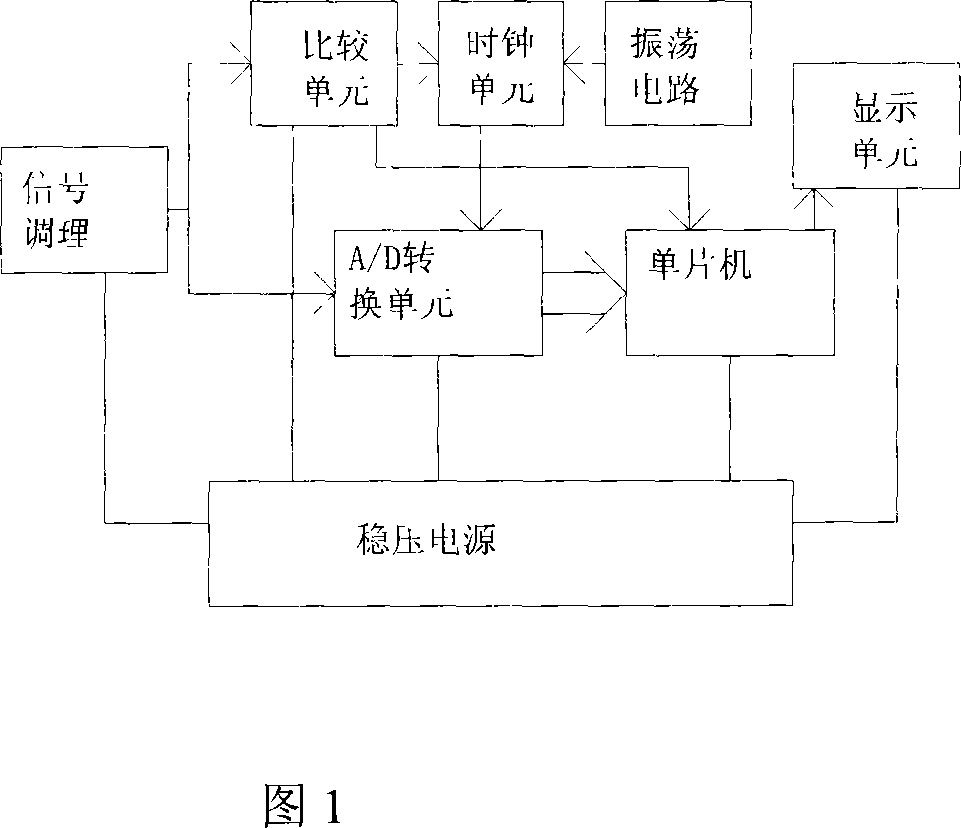

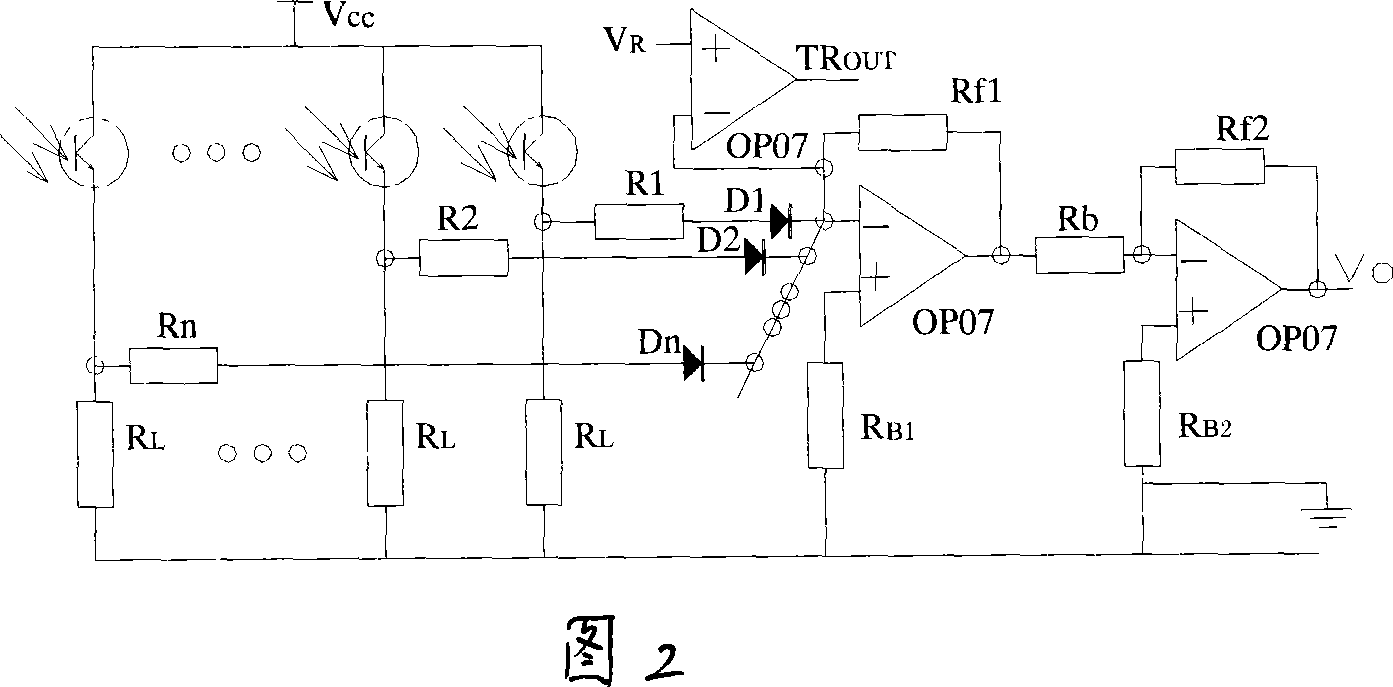

[0015] The present invention is further described with reference to the accompanying drawings and embodiments. As shown in FIG. 1, the present invention is composed of a single-chip microcomputer, a signal conditioning unit, a comparison unit, a clock unit, an oscillation unit, an A / D conversion unit, a display unit and a regulated power supply; such as As shown in Figure 2, the voltage signals on the emitter resistors of each phototransistor connected in parallel are added by the adder OP07, and the phototransistor is used as a photosensitive sensor to form the front-end signal acquisition unit of the textile grey fabric defect detector. The function of the diode in Figure 2 can not only prevent the mutual influence of the signals from each other, but also ensure that only the signal with a certain amplitude (the threshold voltage of the diode) can be transmitted to the input end of the adder OP07, which ensures that there is no defect in the cloth section without defects. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com