Water pressure burst hole and burst method with energy saving and environment friendship

An energy-saving and environmental protection engineering, hydraulic blasting technology, which is applied in blasting and other directions, can solve the problems of dust polluting the environment and not being able to fully utilize the energy of explosives, and achieve the effects of improving economic benefits, energy utilization, and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach 1

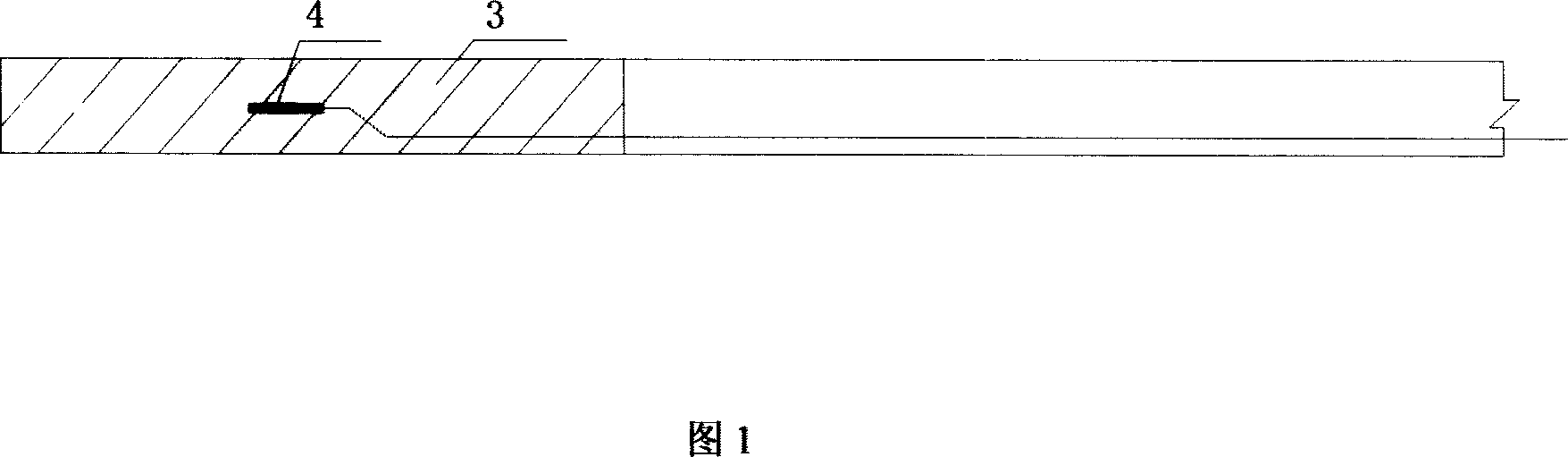

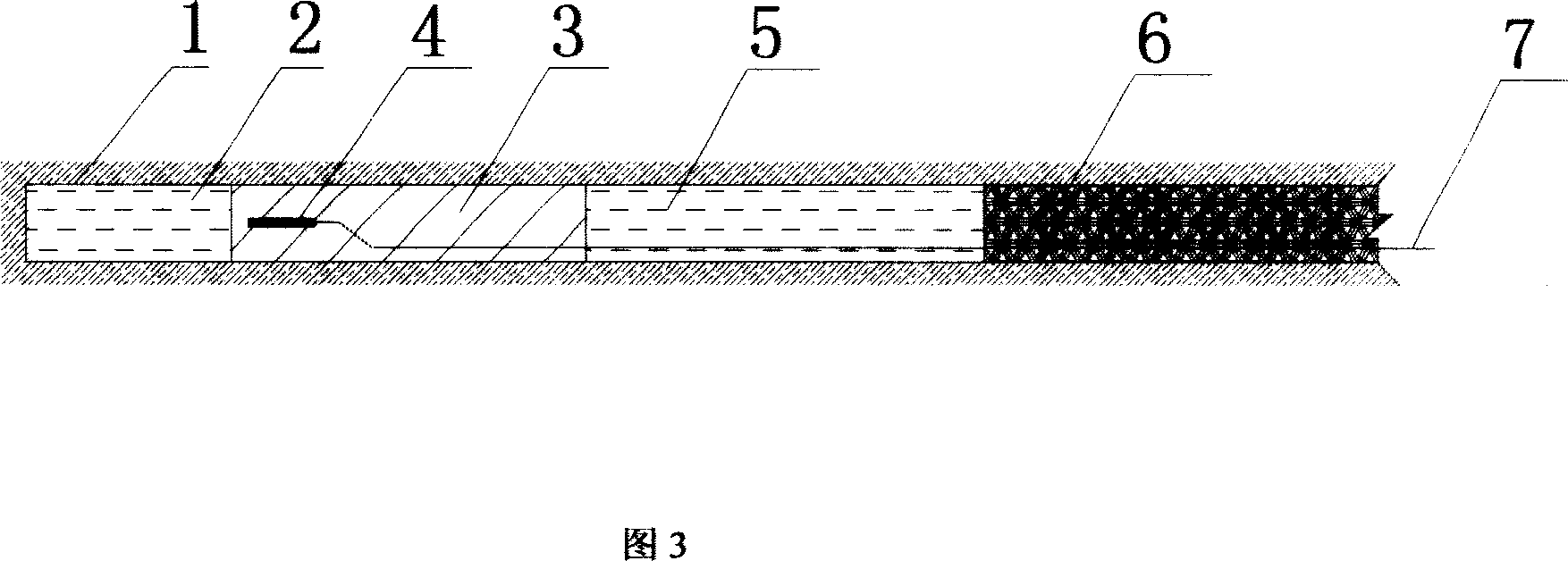

[0038] Test plan 1: blast hole 1 is 3.8 meters deep, water column layer 2 is 20 cm deep, explosive layer 3 is 2.6 meters deep, water column layer 5 is 60 cm deep, backfill plugging layer 6 is 60 cm deep

test approach 2

[0039] Test plan 2: blast hole 1 is 4 meters deep, water column layer 2 is 20 cm deep, explosive layer 3 is 2.4 meters deep, water column layer 5 is 60 cm deep, and backfill plugging layer 6 is 80 cm deep

[0040] Test 1: Open-pit deep-hole hydraulic blasting was carried out in six different sites. Aiming at different geology, different step heights, and different drilling diameters, 2,952 blastholes were actually blasted, and more than 150,000 cubic meters of rock were blasted. Compared with backfilling the hole with soil for deep hole blasting in the past, it saves more than 20% of explosives and more than 18.6% of cost.

[0041] Test 2: Scale test of shallow hole hydraulic blasting, blasting 95,000 cubic meters of stone, and achieved good technical results compared with shallow hole blasting blocked by backfilling with soil, as shown in Table 2.

[0042] blasting

Types of

unit

medication

reduce hundred

Ratio (%)

vibration speed

(cm / s)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com