New type of frame supported shear wall structure and its making process

A manufacturing method and technology of shear walls, applied in the direction of walls, building components, building structures, etc., can solve problems affecting building functions and large cross-sections, and achieve high rigidity, high structural bearing capacity, deformation capacity and energy consumption powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

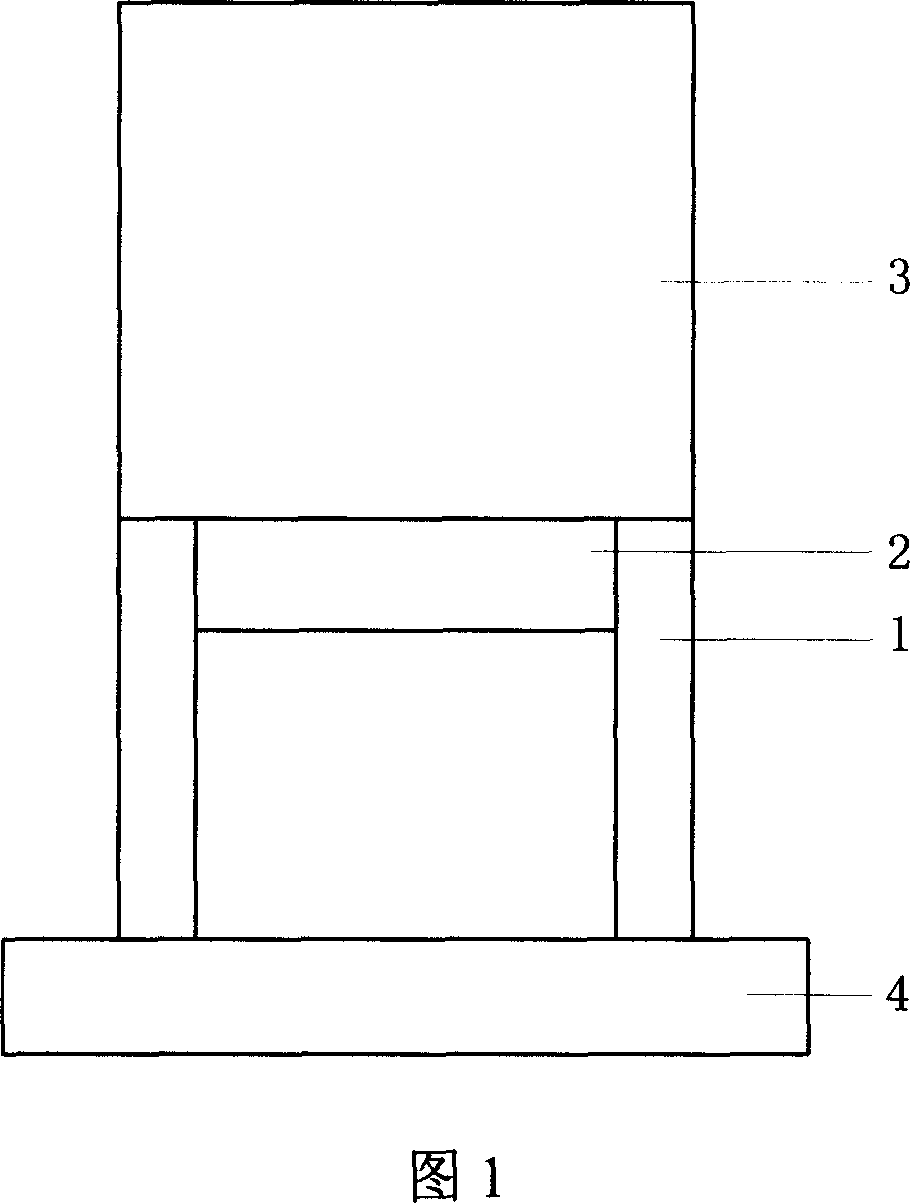

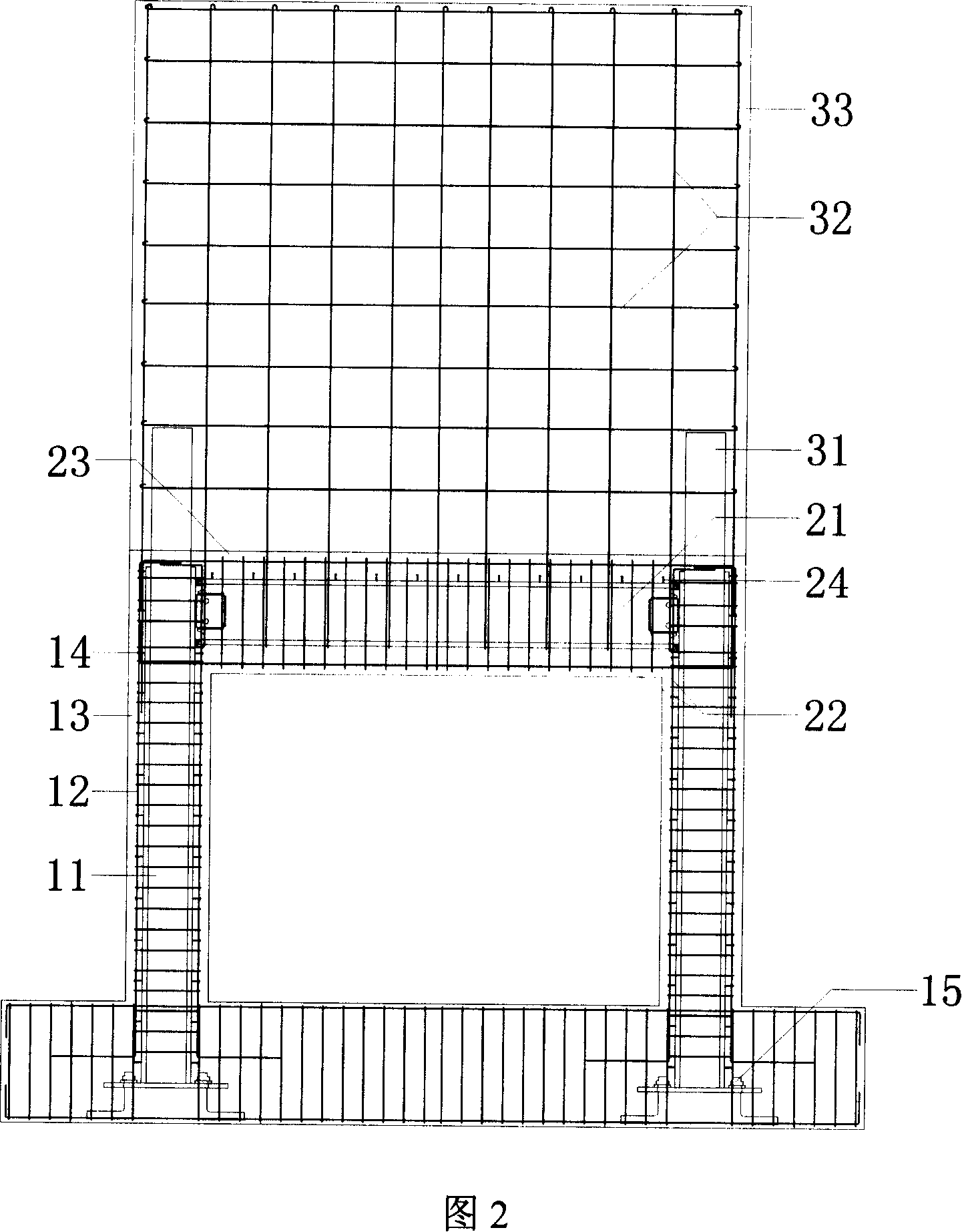

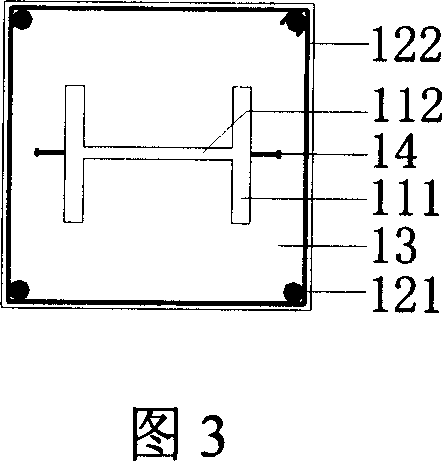

[0024] The invention relates to a bottom large-space frame-supported shear wall related to structural engineering, which includes a frame pillar 1, a transfer beam 2, a shear wall 3 and a foundation 4. Frame pillar 1 comprises shaped steel 11, reinforcing bar 12, concrete 13, stud 14 and column foot anchor bolt 15, wherein, shaped steel is made up of column shaped steel flange 111, column shaped steel web 112 and stiffener 113, and reinforcing bar is made up of longitudinal bar 121 and Stirrup 122 is formed. The length of the column steel 11 extending into the upper shear wall should not be less than half of the upper shear wall height. If it is restricted, only the column steel web 112 can be extended into the upper shear wall, and the extension length should not be less than the upper shear wall. half the height of the wall. The studs 14 should be arranged on the profiled steel flange 111 along the full height of the column. The transfer beam 2 is composed of profiled stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com