Compound polymer electrolytic material and preparation method thereof

A technology of electrolyte materials and polymers, applied in the field of composite polymer electrolyte materials and their preparation, can solve the problems of plastic crystal materials being fragile and difficult to prepare, and achieve the effects of low cost, simple preparation method, and increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1P (VDF-HFP) / LiTFSI / succinonitrile system

[0031] Weigh 1g P(VDF-HFP) and 0.8g LiTFSI and different weights (0%~74%) of succinonitrile (SN), the percentage of succinonitrile is according to the percentage of succinonitrile [P(VDF-HFP) +LiTFSI+SN] total weight calculation, (component expression is: (1-x)[P(VDF-HFP)-LiTFSI]-(x)SN), these three substances are mixed, then dissolved with acetone, Stir until uniform, and then pour the solution on the tetrafluoro mold, in N 2 The solvent was evaporated under atmosphere protection, and dried in a vacuum oven at 30° C. for two days.

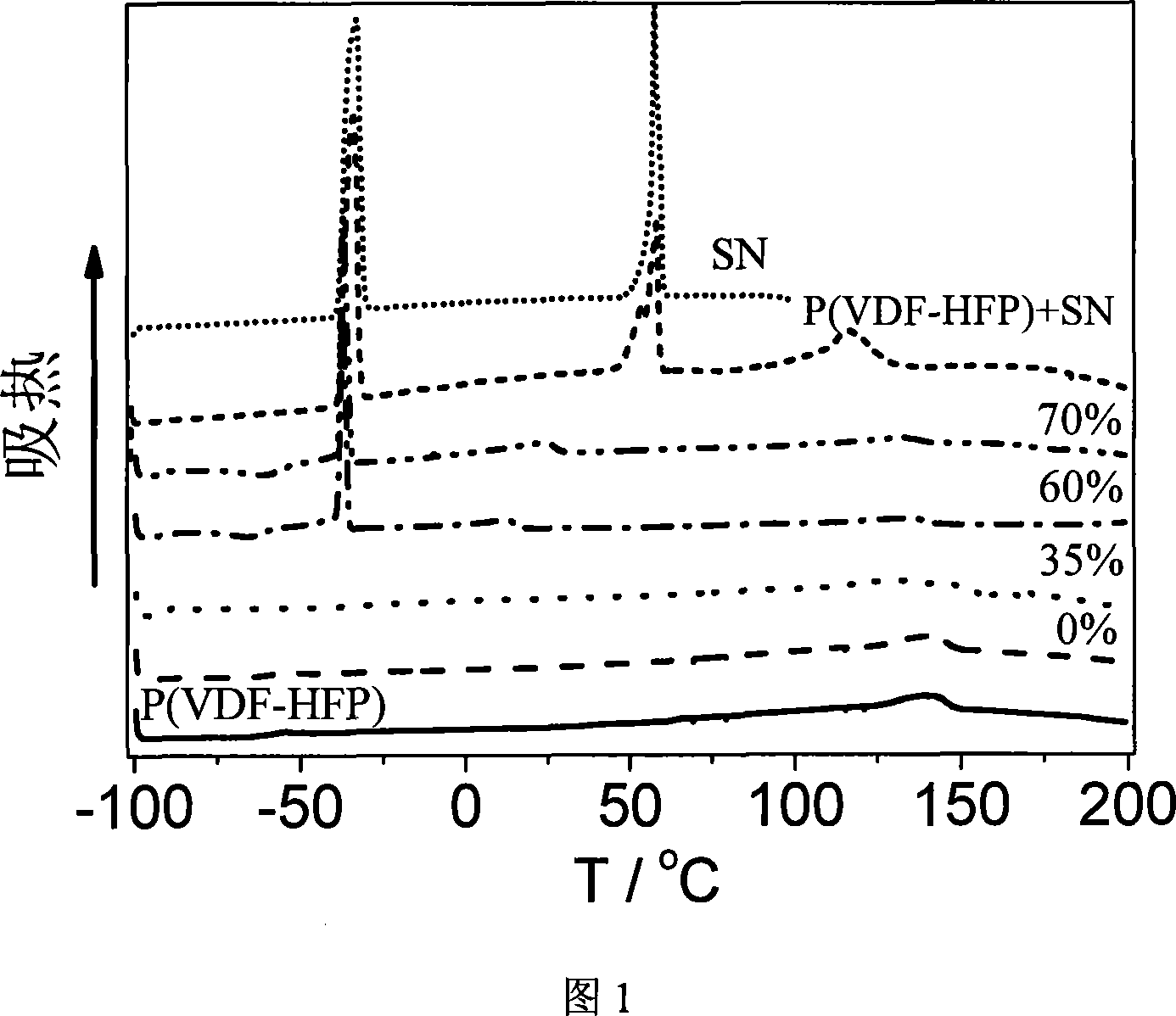

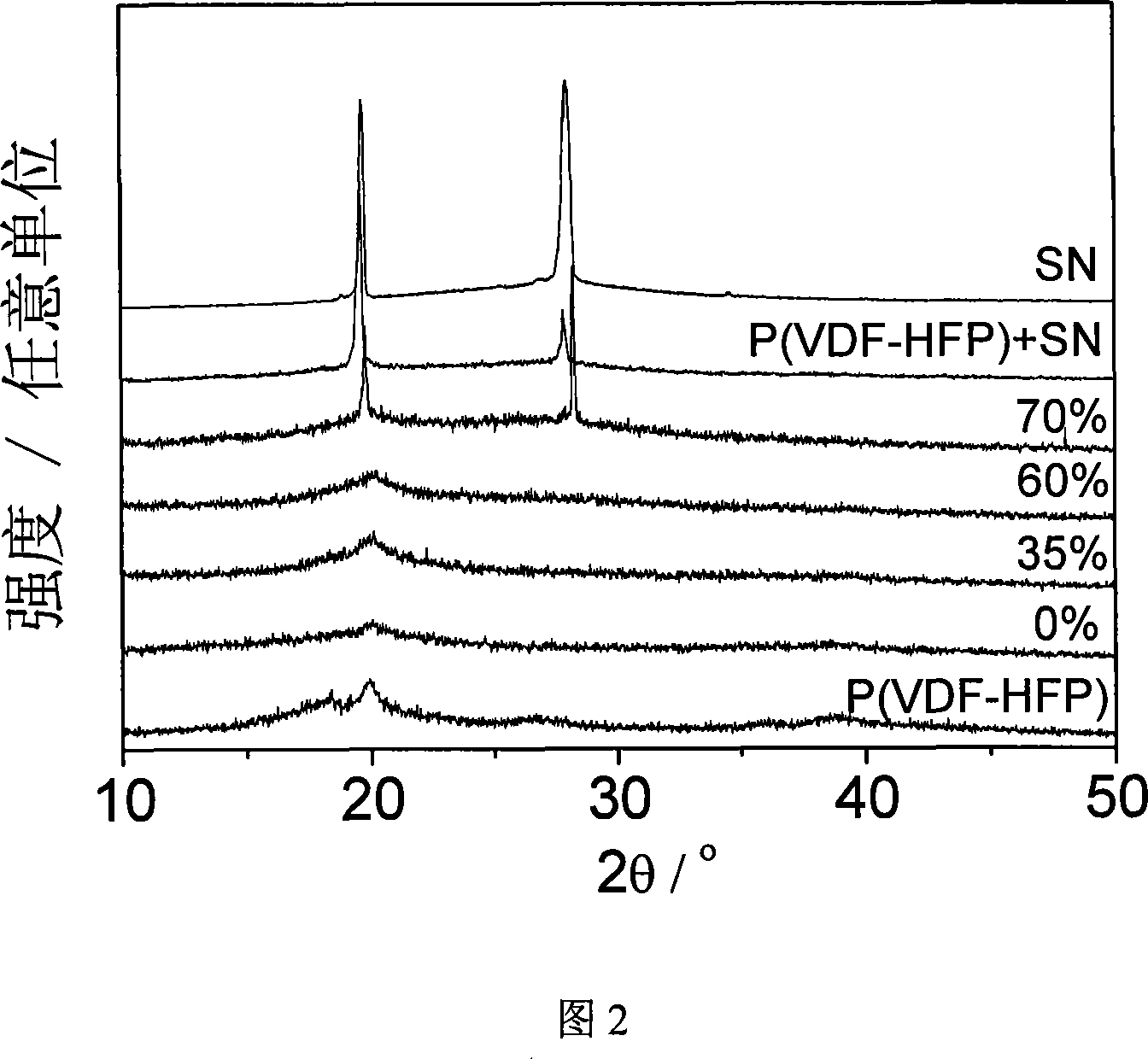

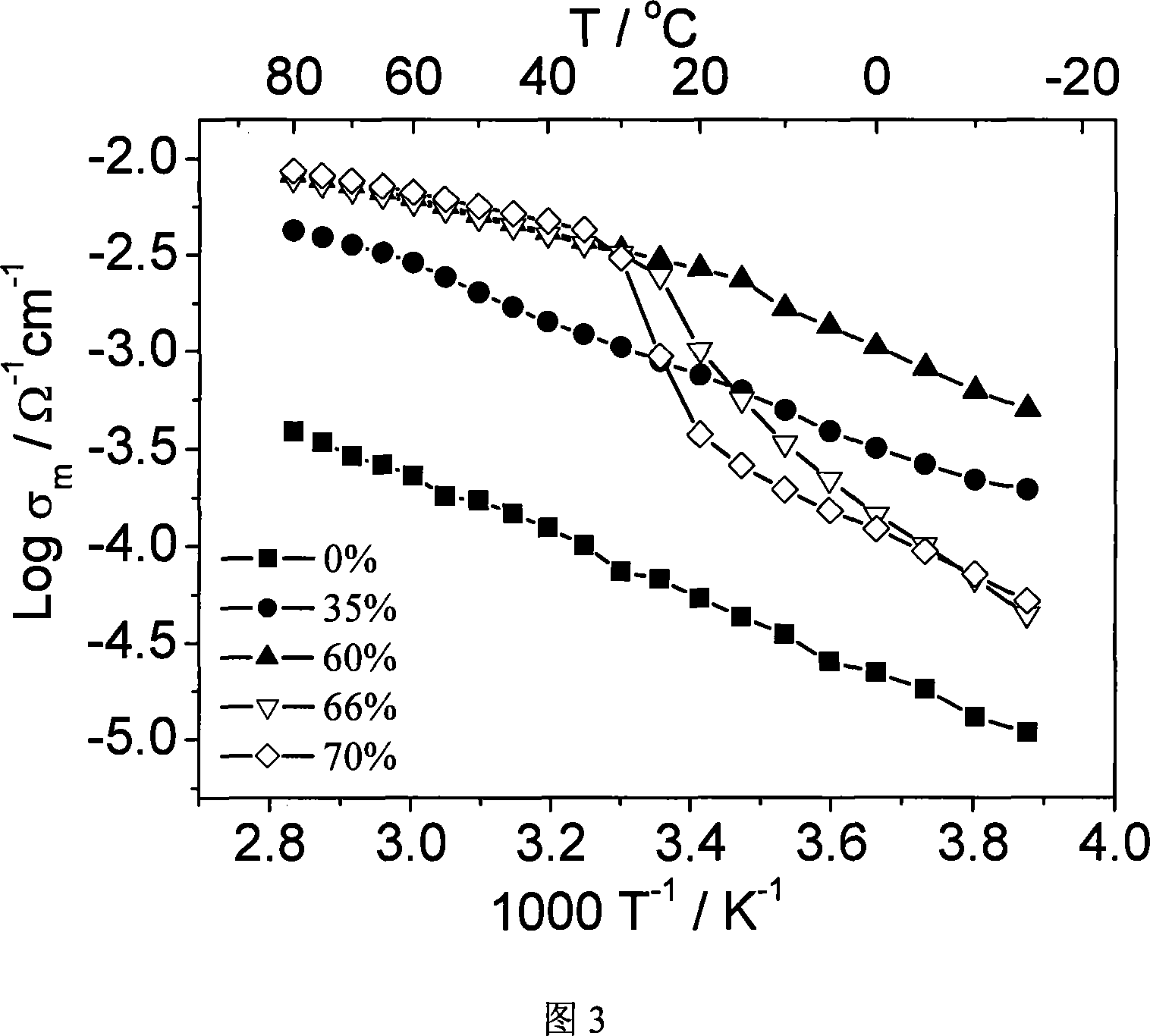

[0032] The thermal properties (Fig. 1), phase composition (Fig. 2), ionic conductivity (Figs. 3 and 4), and mechanical properties (Fig. 5) of the as-prepared samples were tested. After analysis and comparison, the following conclusions are drawn:

[0033] 1) When the succinonitrile content is 0% to 74%, the prepared composite electrolyte is a self-supporting film with a certain strengt...

Embodiment 2

[0036] Embodiment 2P (VDF-HFP) / LBETI / succinonitrile system

[0037] Take a certain amount of P(VDF-HFP, LBETI and succinonitrile, so that the ratio of P(VDF-HFP)+SN and LiBETI remains 80% and 20%, specifically, weigh 0.76g LBETI, P( The total weight of VDF-HFP) and succinonitrile remains 3g (component expression is: 80% [(1-x) P (VDF-HFP)-(x) SN]-20% LiBETI), this three The two substances are mixed, then dissolved with acetone, stirred until uniform, and then the solution is poured on the tetrafluoro mold, in N 2 The solvent was evaporated under atmosphere protection, and dried in a vacuum oven at 30° C. for two days.

[0038] Thermal properties (Figure 6), XRD (Figure 7), ion conductivity (Figures 8 and 9) and mechanical properties tests (Figure 10) were performed on the prepared samples. After analysis and comparison, the following conclusions are drawn:

[0039] 1) When the succinonitrile content is 0% to 67%, the prepared composite electrolyte is a self-supporting film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com