Plane spring capable of eliminating short-range vibratory

A flat spring, short-range technology, applied in the field of flat springs, can solve the problems of tearing, impact, and lack of popularization of plug sockets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings, and embodiments of the present invention will be given.

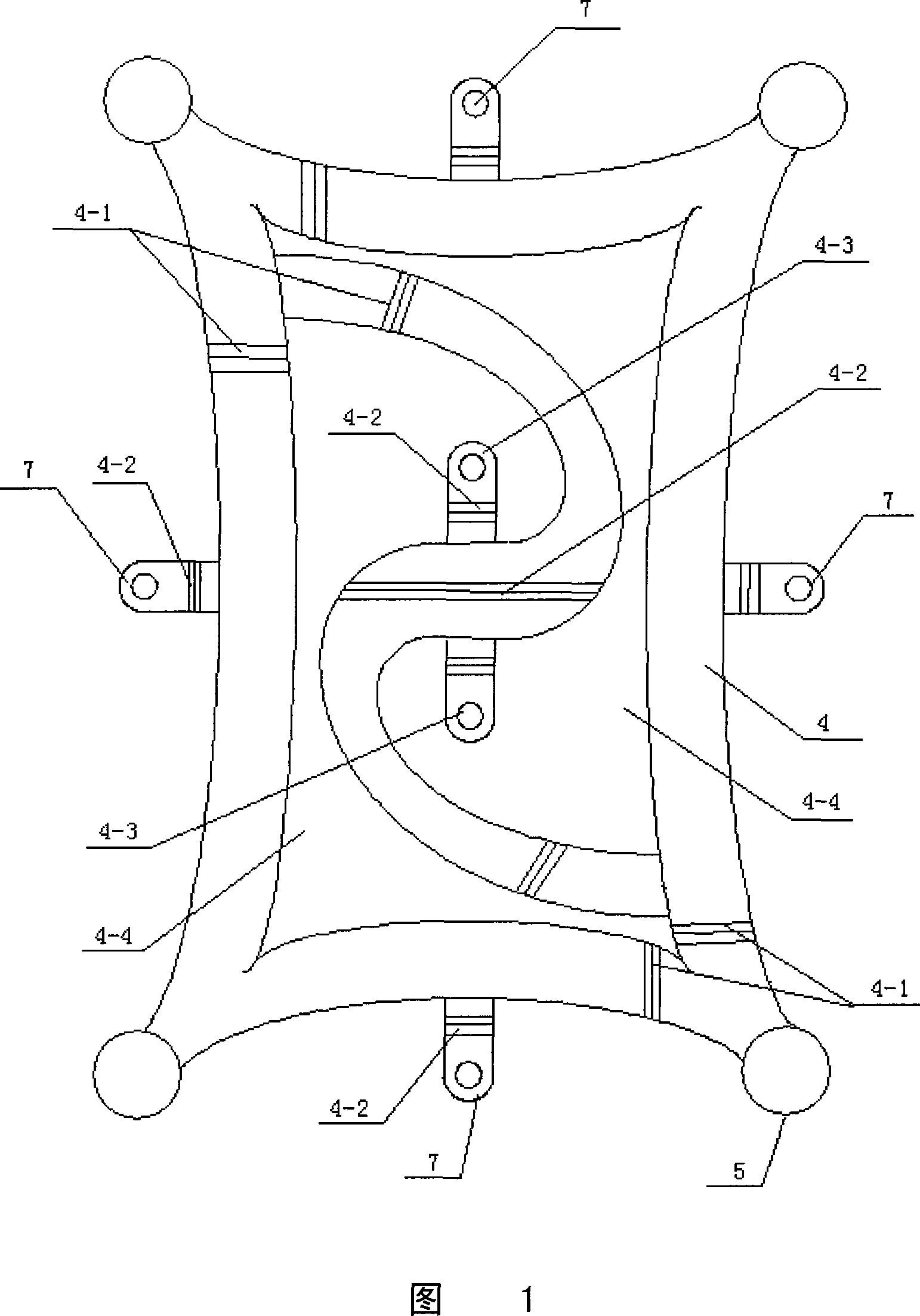

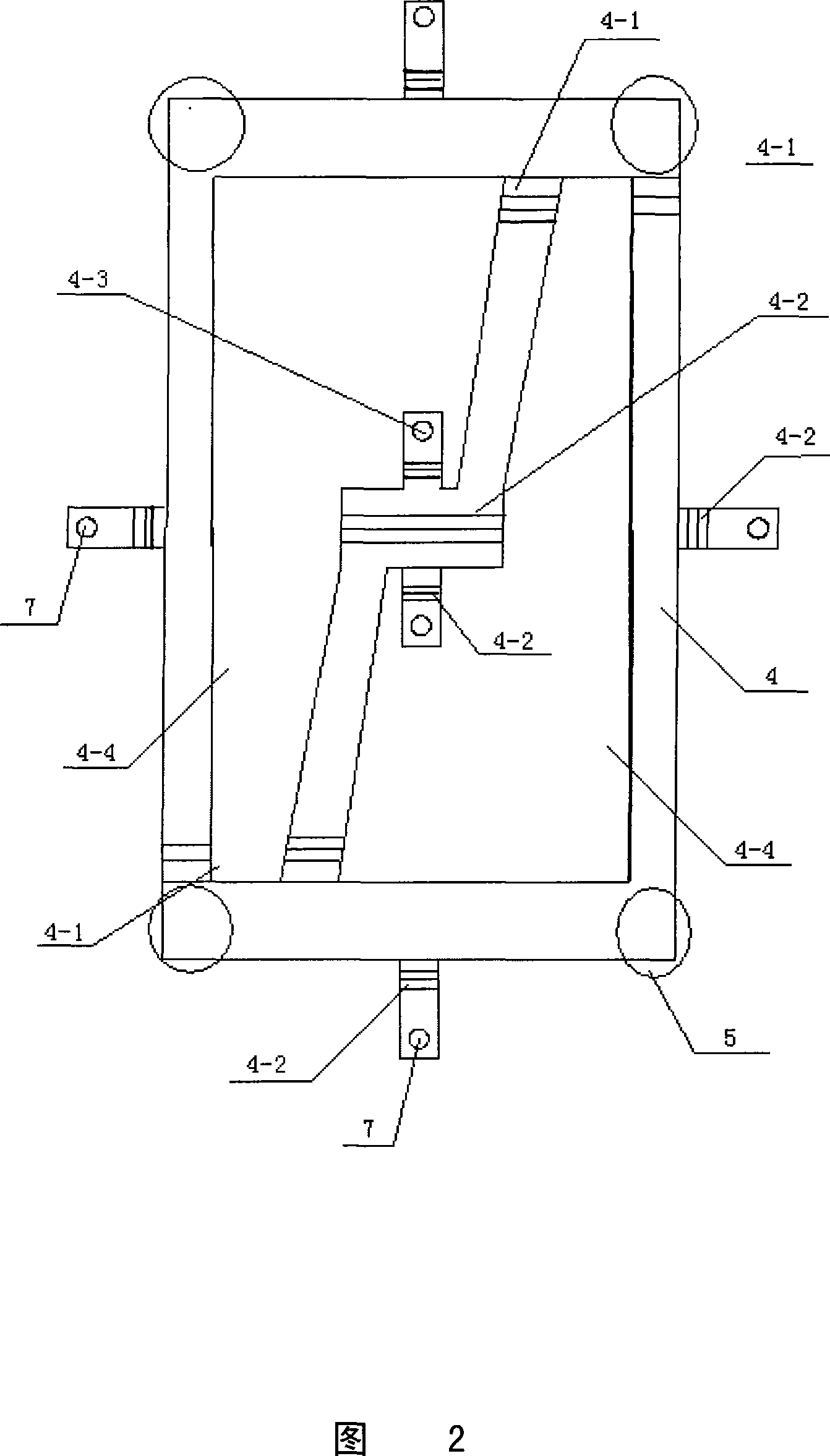

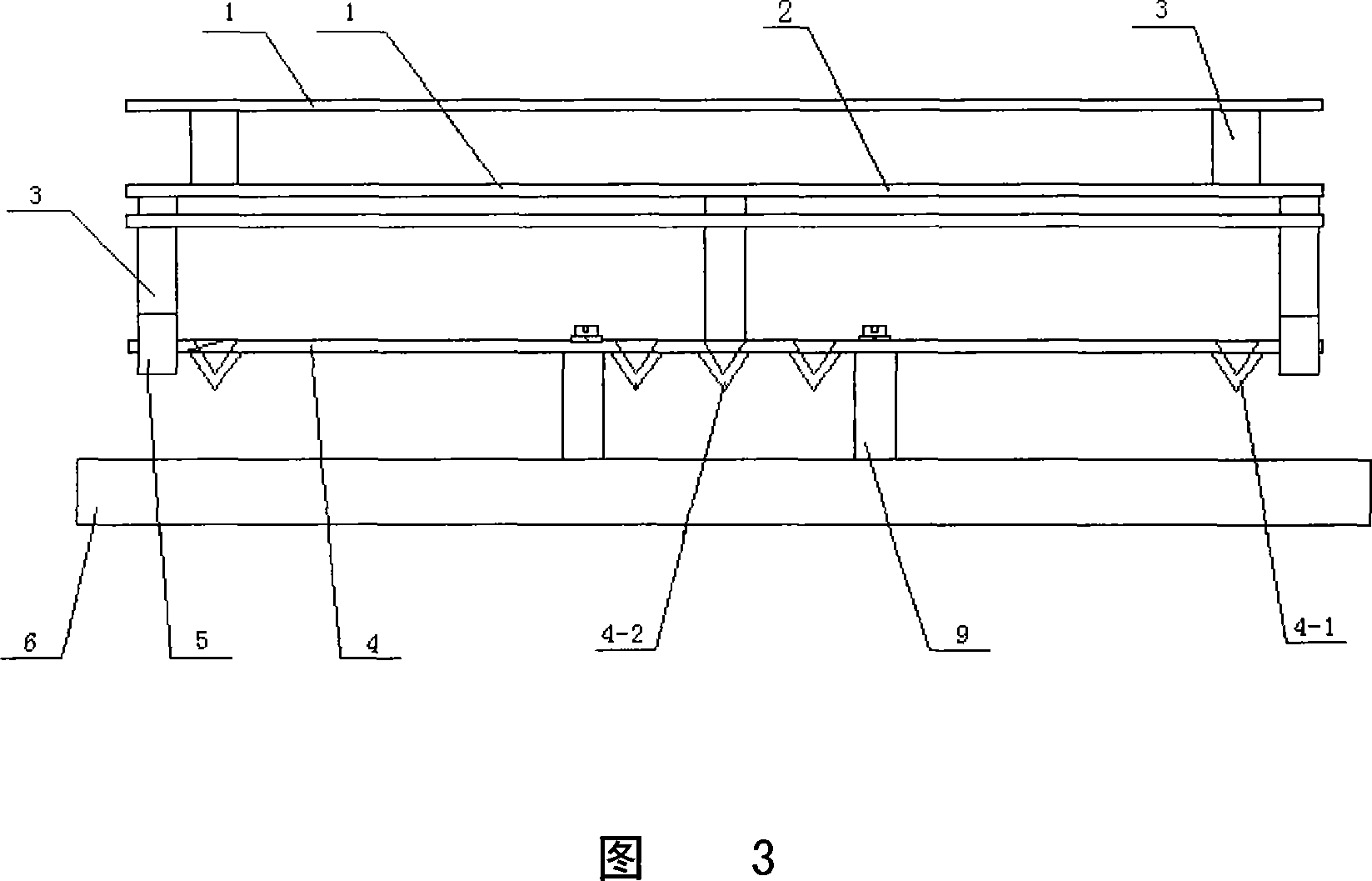

[0013] This planar spring 4 that eliminates short-range vibrations as shown in the figure is a quadrangular sheet (seeing accompanying drawing 1,2), is provided with a rotationally symmetrical planar spring hollowed out area 4-4 in the middle of the frame, is provided with between two hollowed out areas There is a planar spring plate body connected with the symmetrical corresponding frame (the middle plane spring plate body in the accompanying drawing 1 is connected with the left and right planar spring frames; in the accompanying drawing 2, the middle plane spring plate body is connected with the upper , the planar spring frame of the lower position is connected); And set on the plate body frame edge of one group of corresponding angles of the planar spring 4 and the center connection spring plate body, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com