Laser processing method and processing device

A laser processing method and laser processing technology, which are applied to lasers, laser welding equipment, laser parts, etc., can solve the problems of time efficiency reduction and achieve high-precision processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

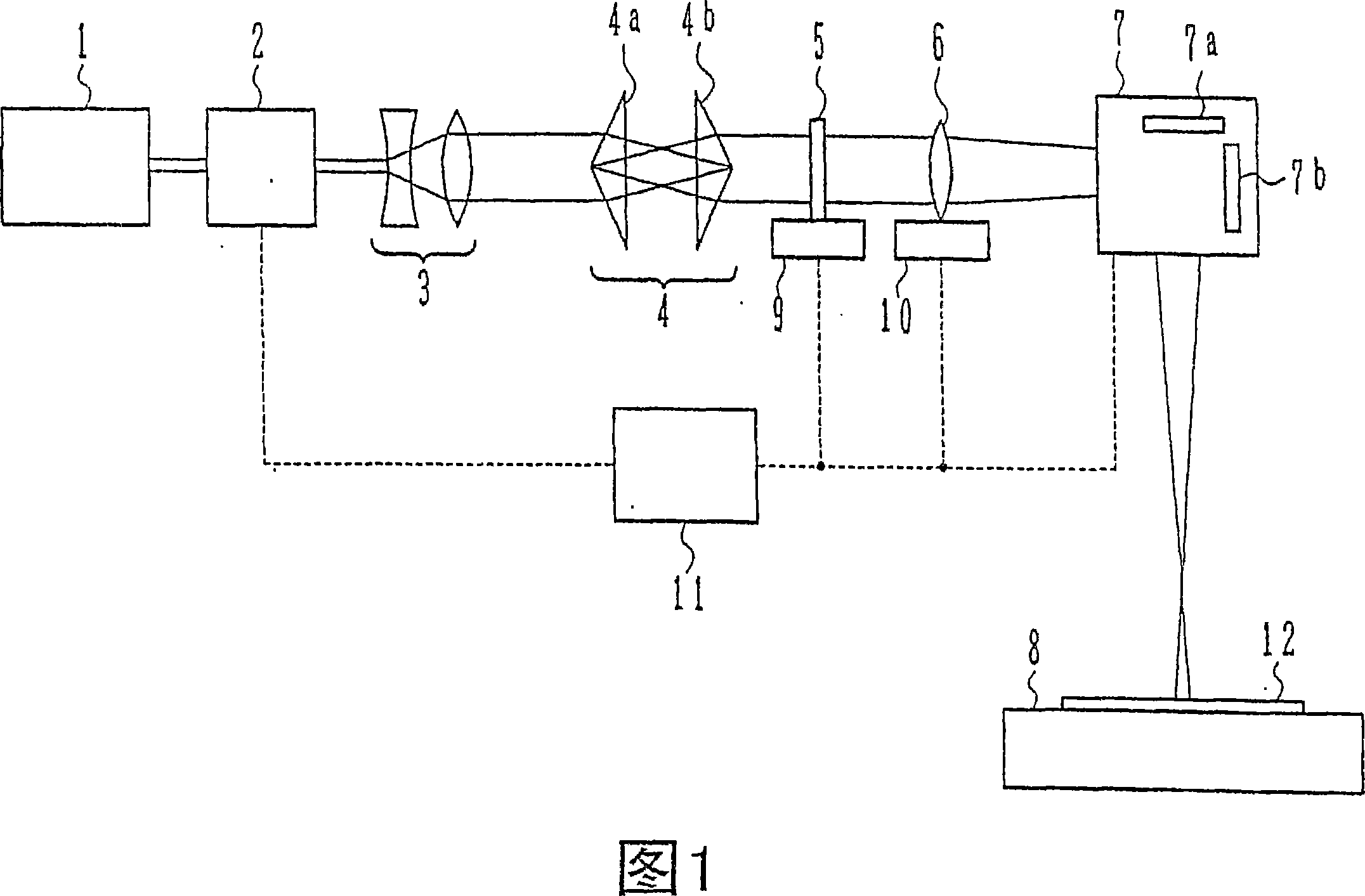

[0074] FIG. 1 is a schematic diagram of a laser processing apparatus for executing a laser processing method according to a first embodiment of the present invention.

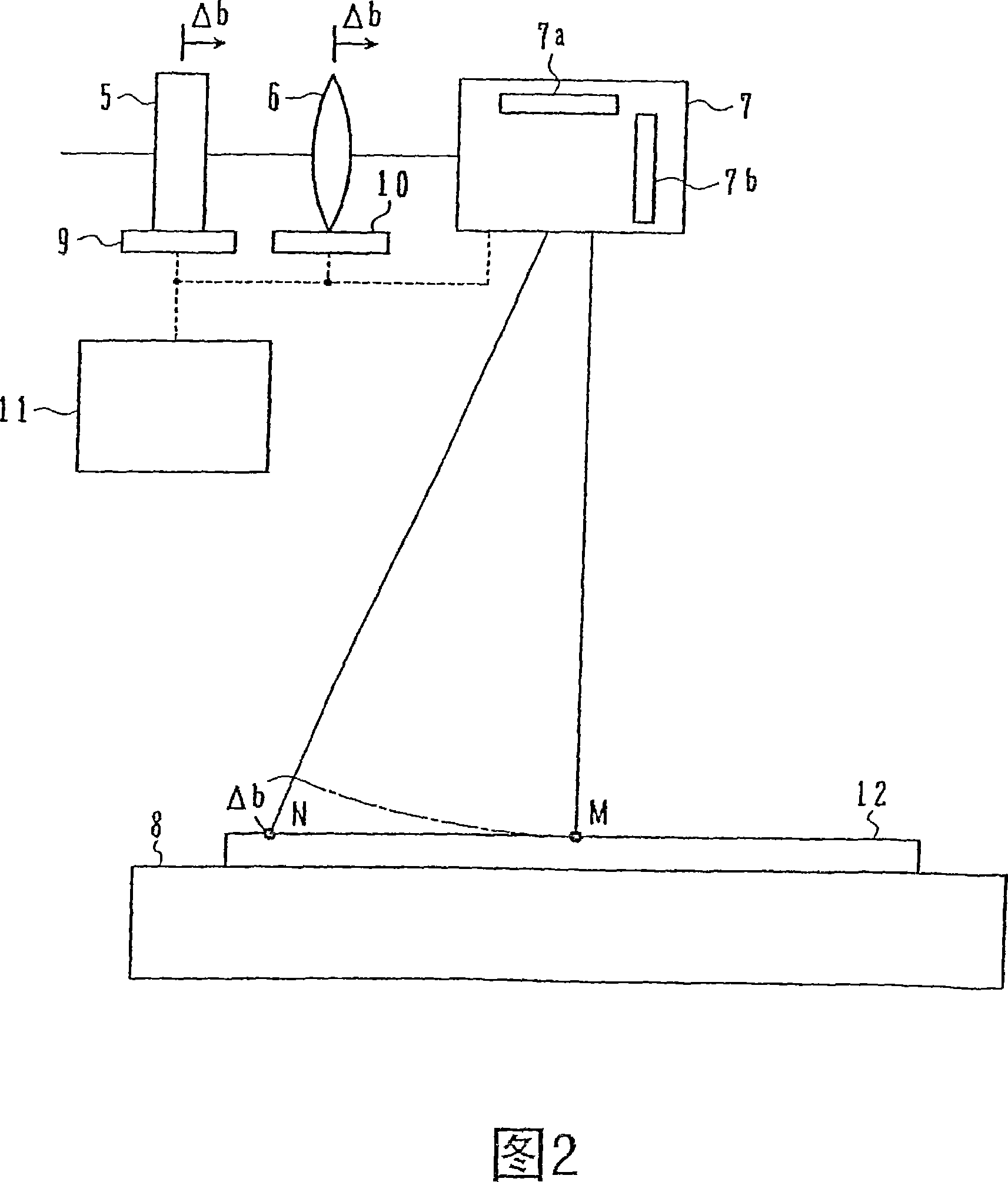

[0075] In the laser light source 1, for example, a Nd:YAG laser oscillator including a wavelength conversion element emits a triple high-frequency wave (wavelength 355nm) of an Nd:YAG laser at a pulse energy of 1 mJ / pulse and a pulse width of 50 ns. The laser beam enters the conical optical system 4 after passing through the variable attenuator 2 that adjusts the pulse energy and the beam expander 3 that expands the beam diameter and emits it as parallel light. The conical optical system 4 includes a pair of conical lenses 4a, 4b. The pair of conical lenses 4 a and 4 b have, for example, the same shape, and are arranged such that their bottom surfaces face each other. The laser beam is incident on the conical lens 4a from the axial direction of the straight cone, so that the center of the beam section coincide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com