Method for producing lactic acid drink containing flesh grains

A technology for pulp granules and pulp, which is applied in the fields of dairy products, milk preservation, food preparation, etc., can solve the problems of inability to achieve large-scale production, uneven content of finished granules, and different treatment methods, so as to enrich product types and products. The effect of good quality and convenient market circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1, the formulated yoghurt drink that is rich in fruit grains

[0067] Formula (according to 1 ton):

[0068] Milk 350.0 kg White sugar: 60.0 kg Acesulfame potassium: 0.2 kg

[0069] Sodium carboxymethyl cellulose: 3.6 kg Citric acid: 2.4 kg Lactic acid: 1.8 kg

[0070] Yellow peach granules: 60.0 kg Peach essence: 0.4 kg Purified water: 521.6 kg

[0071] Raw material standards:

[0072] Yellow peach granules: size 3×3×3mm, pH: 3.8, sugar content: 30BX, fruit content: 61.0%;

[0073] Other raw and auxiliary materials meet the relevant national standards.

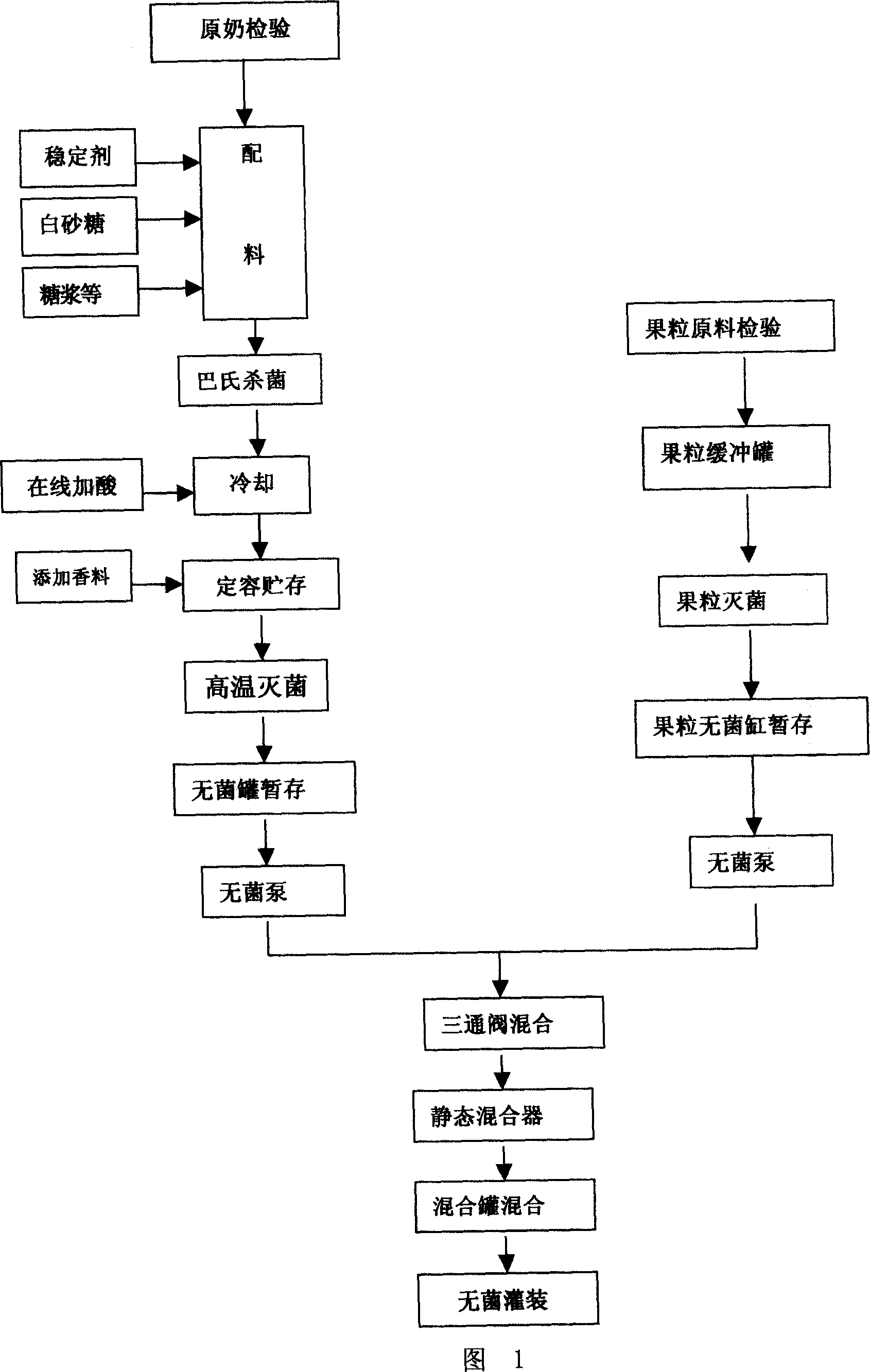

[0074] The process flow chart of the production process is shown in Figure 1, and the specific process is as follows:

[0075] 1. Milk ingredients:

[0076] 1 Raw milk inspection: mainly for sensory indicators, acidity, fat, protein, whole milk solids, adulteration, alcohol test and other indicators, which meet the relevant national standards.

[0077] 2. Ingredients:

[0078] a. Dissolution of thick...

Embodiment 2

[0099] Embodiment 2, the lactic acid bacteria drink that is rich in coconut fruit pulp

[0100] Formula (according to 1 ton):

[0101] Yogurt: 400.0 kg White sugar: 40.0 kg High fructose syrup (70.0%): 60.0 kg

[0102] Coconut: 85.0 kg Pectin: 3.6 kg Citric acid: 1.5 kg Yogurt essence: 0.3 kg

[0103] Purified water: 409.6 kg

[0104] Raw material standard:

[0105] The size of coconut fruit is 3×4×4mm, PH: 4.5, sugar content: 15BX, fruit content: 70.0%;

[0106] Other raw and auxiliary materials meet the relevant national standards.

[0107] making process:

[0108] 1. Milk ingredients:

[0109] 1. Preparation of yoghurt: use Hansen YM-381 strain for fermentation, the acidity (titration acidity) of the yoghurt reaches 80°T and then rapidly cools down to below 10°C, and the acidity of the yoghurt is controlled within the range of 80--90°T.

[0110] 2. Ingredients:

[0111] a. Weigh the prepared yogurt into the batching tank according to the formula.

[0112] b. Dissol...

Embodiment 3

[0133] Embodiment 3 contains the yoghurt drink of coconut fruit and strawberry composite fruit

[0134] Formula (according to 1 ton):

[0135] Milk: 450.0 kg White sugar: 45.0 kg Neotame: 0.0075 kg

[0136] Coconut granules: 65.0 kg Strawberry granules: 25.0 kg Pectin 3.0 kg

[0137] Microcrystalline cellulose 1.0 kg Monostearate 0.5 kg Lactic acid: 2.0 kg

[0138] Citric acid: 2.5 kg Yogurt essence: 0.5 kg Purified water: 402.5 kg.

[0139] Raw material standards: Raw and auxiliary materials comply with relevant national standards.

[0140] making process:

[0141] 1. Milk ingredients:

[0142] 1 Raw milk inspection: mainly for sensory indicators, acidity, fat, protein, whole milk solids, adulteration, alcohol test and other indicators, which meet the relevant national standards.

[0143] 2. Ingredients:

[0144] a. Dissolution of stabilizer: mix stabilizer: white granulated sugar=1:4, mix evenly; dissolve in 400 kg of pure water at 80°C, after fully dissolved, pour in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com