Sterilization equipment for bottled yoghurt drinks

A technology for sterilization equipment and beverages, applied in the field of sterilization of yogurt, can solve the problem of incomplete sterilization of bottled yogurt, and achieve the effect of sterilization without dead ends and complete sterilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

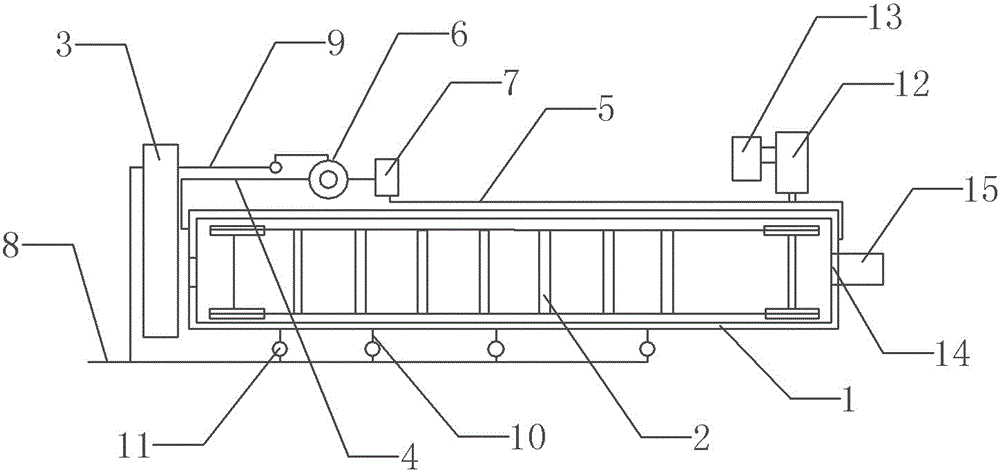

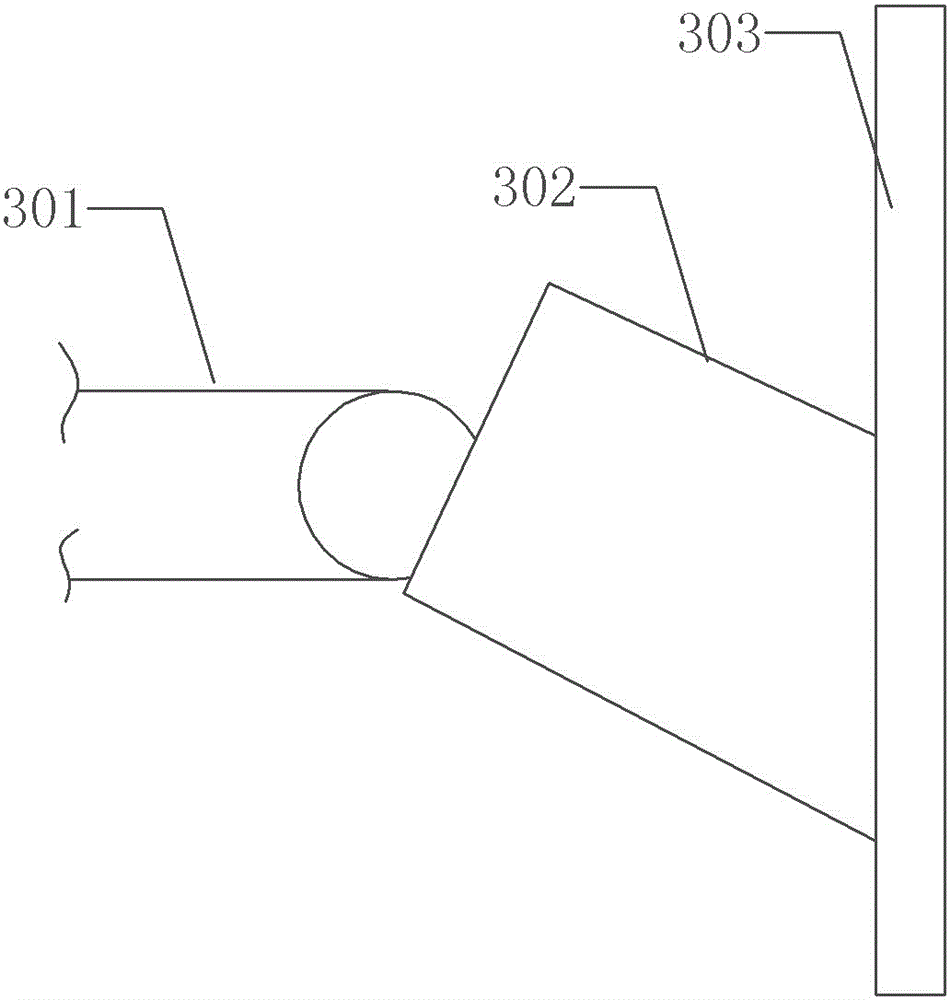

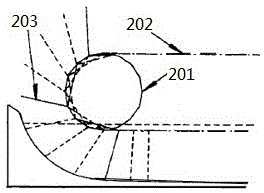

[0019] The reference numerals in the accompanying drawings of the description include: sterilization pool 1, scraper conveying mechanism 2, first sprocket 201, first group of chains 202, scraper 203, articulated arm 2031, push arm 2032, first pin shaft 2033, Second pin shaft 2034, conveyor belt 301, material guide trough 302, bottle outlet door 303, water inlet pipe 4, water outlet pipe 5, steam-water mixer 6, circulating water pump 7, steam inlet pipe 8, branch pipe 9, steam heating pipe 10, Pneumatic film regulating valve 11, transmission mechanism 12, motor 13, bottle outlet 14, bottle outlet chute 15, first sprocket shaft 16, guide rail 17, upper limit plate 18.

[0020] as attached figure 1 Shown: the sterilizing equipment for bottled yoghurt drinks in this embodiment includes a sterilizing tank, which is respectively connected to the water inlet pipe and the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com