Sealing device for steel ball conveying and press-in of lithium ionic cell

A lithium-ion battery and sealing device technology, which is applied in the direction of secondary batteries, battery pack parts, circuits, etc., can solve problems such as the inability to reduce production costs, uneven force of artificial smashing balls, and quality problems of battery products, so as to avoid battery damage. The effect of liquid leakage, solving the problem of low yield rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

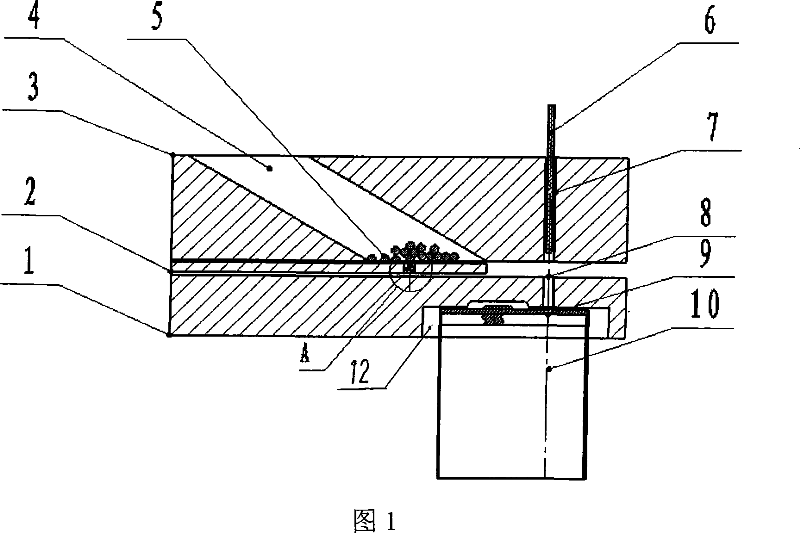

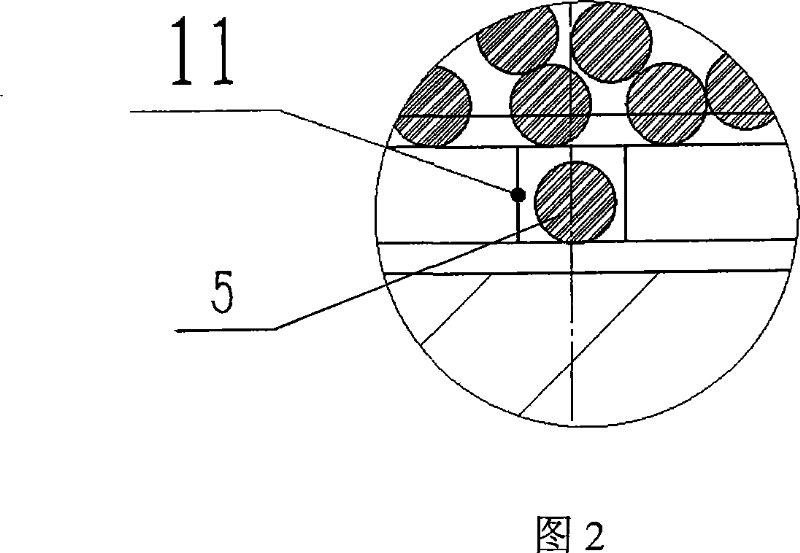

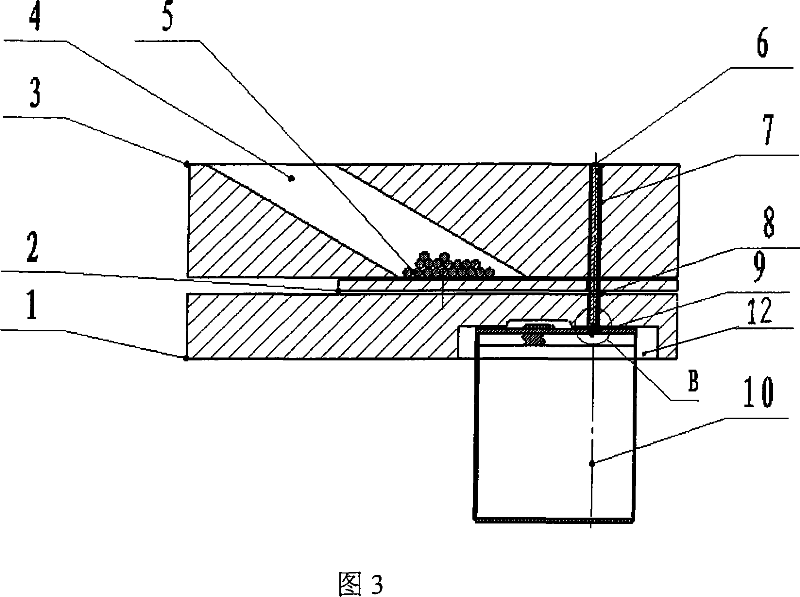

[0015] As shown in Figures 1 to 4, a sealing device for lithium-ion battery steel ball conveying and pressing, the device includes a corresponding upper template 3 and a lower template 1, and a sliding plate 2 is arranged in parallel between them. The sliding plate 2 is provided with a ball moving hole 11; the upper template 3 has a ball holding cavity 4 for conveying the steel ball 5 obliquely from top to bottom; the bottom of the lower template 1 is provided with a battery 10 The cavity 12 of the battery cavity 12 is provided with a steel ball introduction hole 8 vertically penetrating the lower template 1; corresponding to the steel ball introduction hole 8 on the lower template 1, the upper template 3 is coaxially and vertically provided with a needle hammer introduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com