Numerical control method of die casting machine and numerical control die casting machine

A die-casting machine and industrial control technology, applied in the field of casting machinery, can solve the problems that the motor cannot control the angular displacement, angular velocity, complicated control mode, and difficult maintenance, etc., and achieve the effects of rich support software, safe and reliable transmission, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

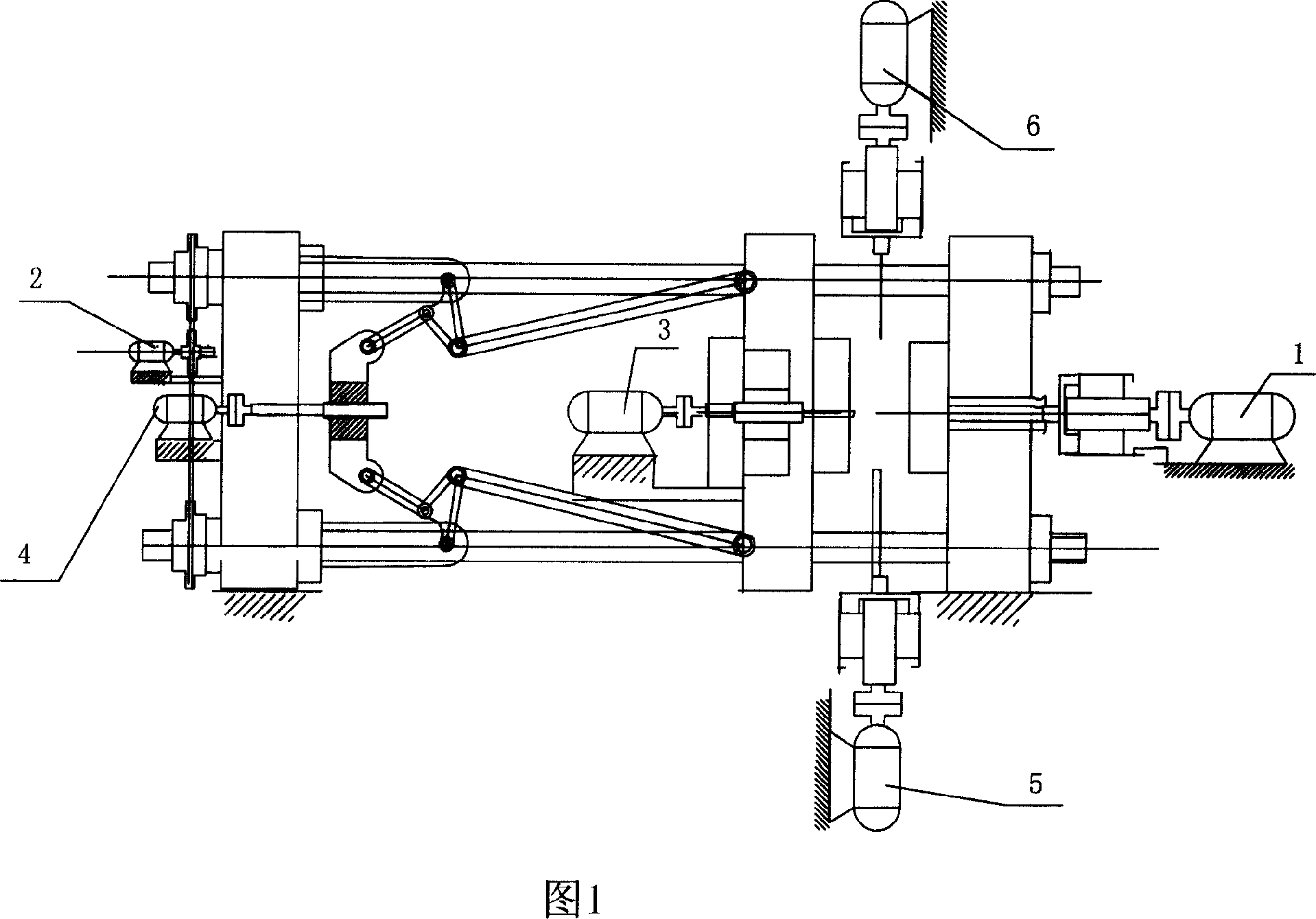

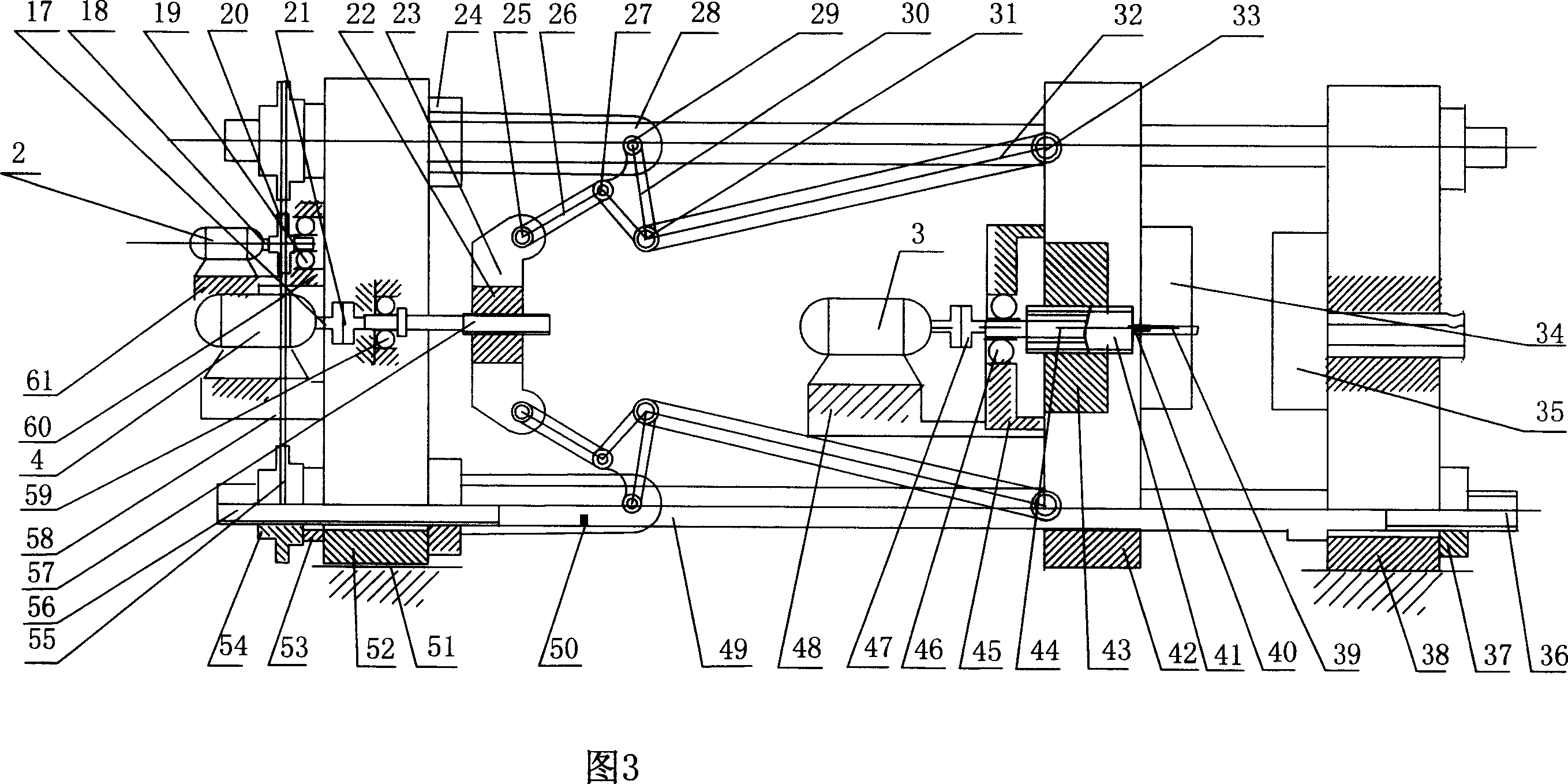

[0028]As shown in Figure 1: The motors of the injection device, mold adjusting device, ejector device, mold clamping device and inserting device of the CNC die-casting machine respectively adopt the switched reluctance speed control injection motor 1, the switch reluctance speed control mold control Motor 2, switched reluctance speed-regulating ejector motor 3, switched reluctance speed-regulating mold clamping motor 4 and switched reluctance speed-regulating plug-in motors 5,6. Switched reluctance speed-regulating injection motor 1, switched reluctance speed-regulating mold-adjusting motor 2, switched reluctance speed-regulating ejector motor 3, switched reluctance speed-regulating mold clamping motor 4 and switched reluctance speed-regulating core-inserting motor 5, 6 are respectively installed on the injection device, the mold adjustment device, the ejector device, the mold clamping device and the inserting core device.

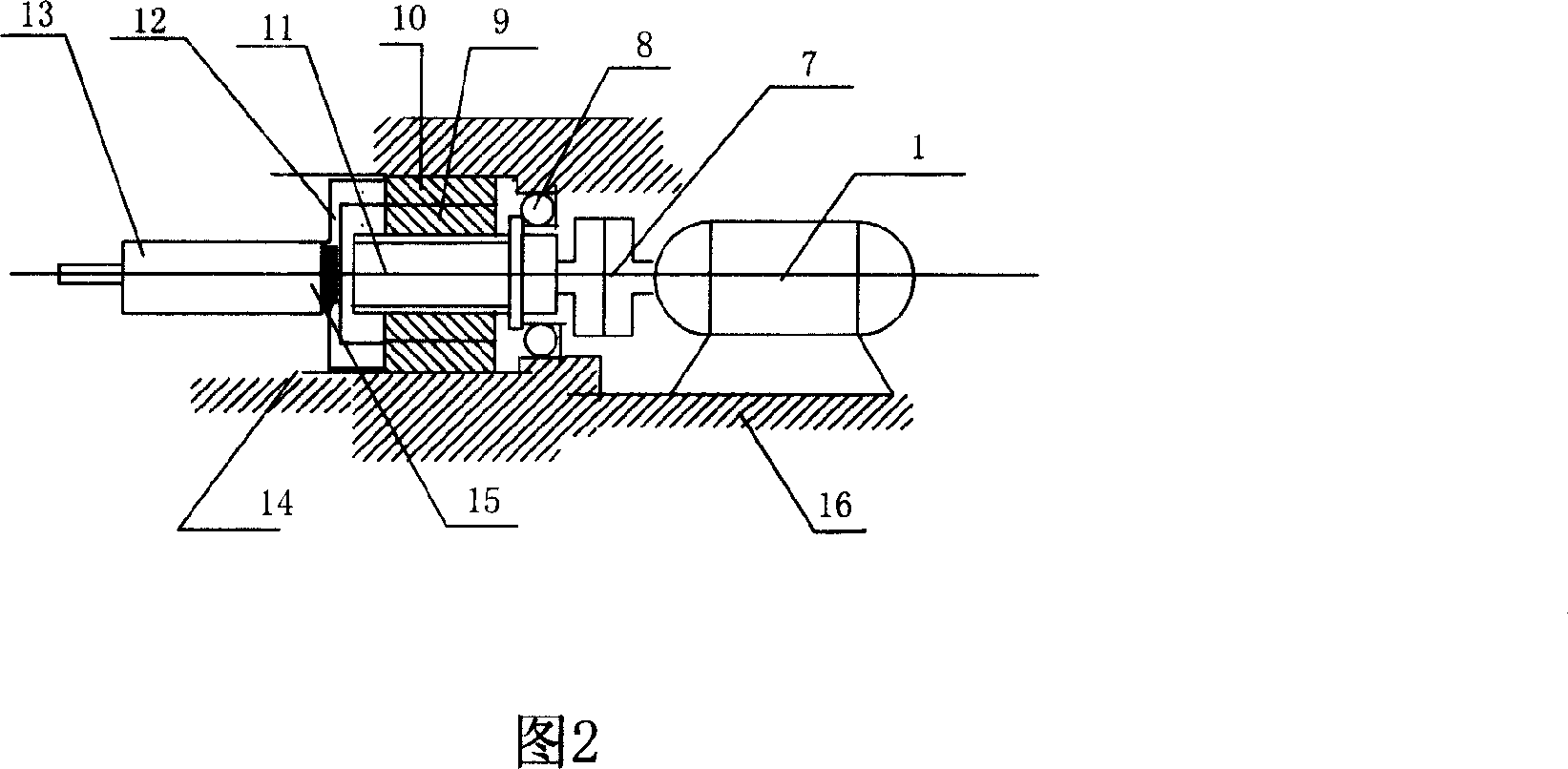

[0029] As shown in Figure 2: the injection device in...

Embodiment 2

[0040] As shown in FIG. 7 : the difference from FIG. 3 of Embodiment 1 is that the rear connecting rod 64 in the clamping device connects the column pin 29 and the column pin 31 , and the middle rod 61 connects the column pin 31 and the column pin 25 . In the ejector device, the screw 65 is connected to the ejector rod 39 through the nut 66, the slider 67 and the connecting plate 69. The screw 65 and the nut 66 are driven by a screw pair, the nut 66 is connected with the slider 67 as a whole, and the slider 67 is slidably connected with the guide rail 68. The connecting plate 69 is integrally connected with the slider 68 , one end of the push rod 39 is integrally connected with the connecting plate 69 , and the guide rail 68 is fixed in the movable template 42 .

Embodiment 3

[0042] As shown in Figure 8: the difference from Figure 3 of Embodiment 1 is that the screw rod 70 and the nut 71 in the mold clamping device are driven by a screw pair, and the nut 71 is connected with the movable template 72 as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com