Numerical controlling pressure tester used in concrete box culvert and testing method therefore

A technology of concrete and tester, which is applied in liquid/vacuum measurement for liquid tightness, and by measuring the increase and deceleration rate of fluid, etc., can solve the problem of inaccurate detection of box culvert expansion joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

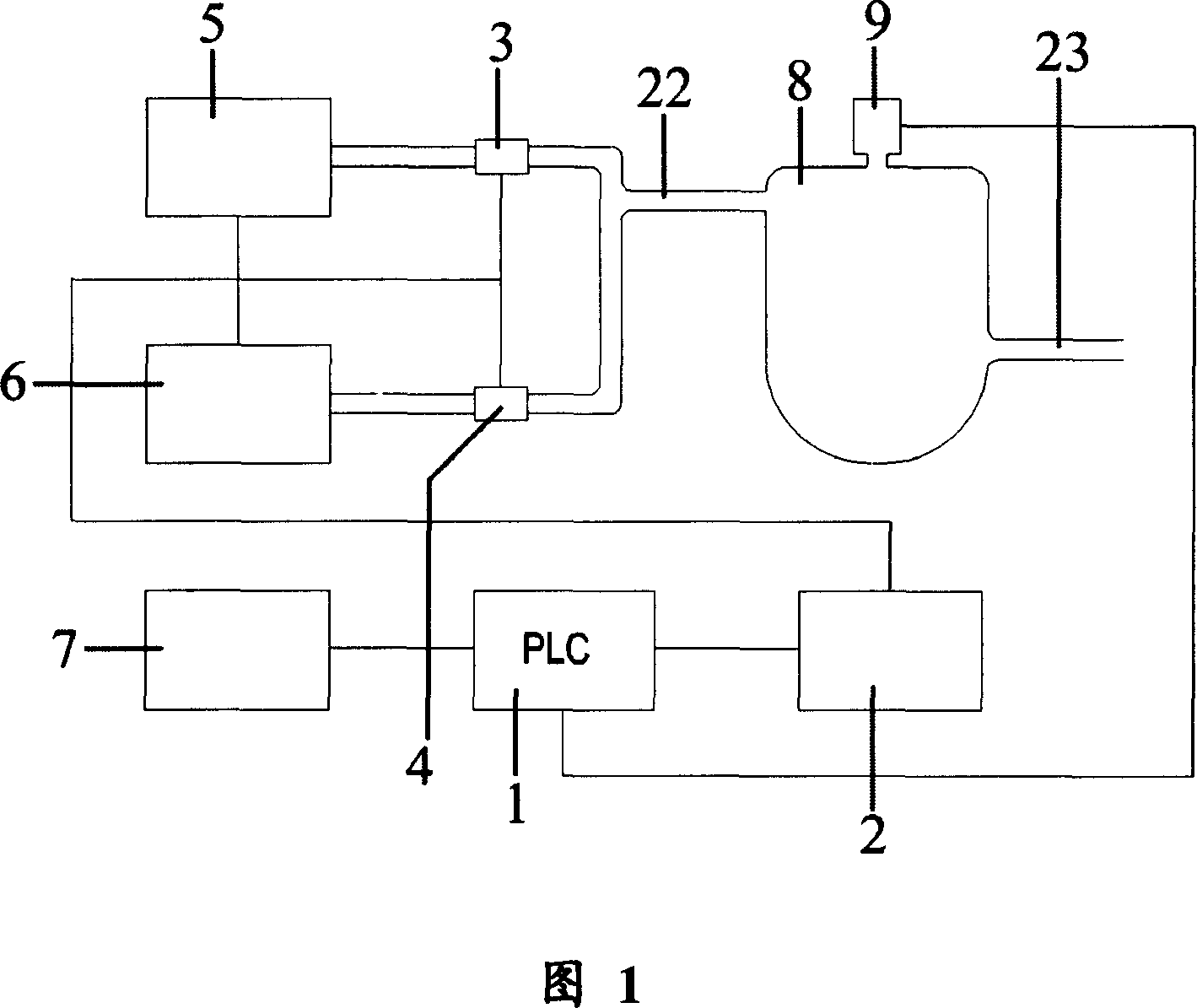

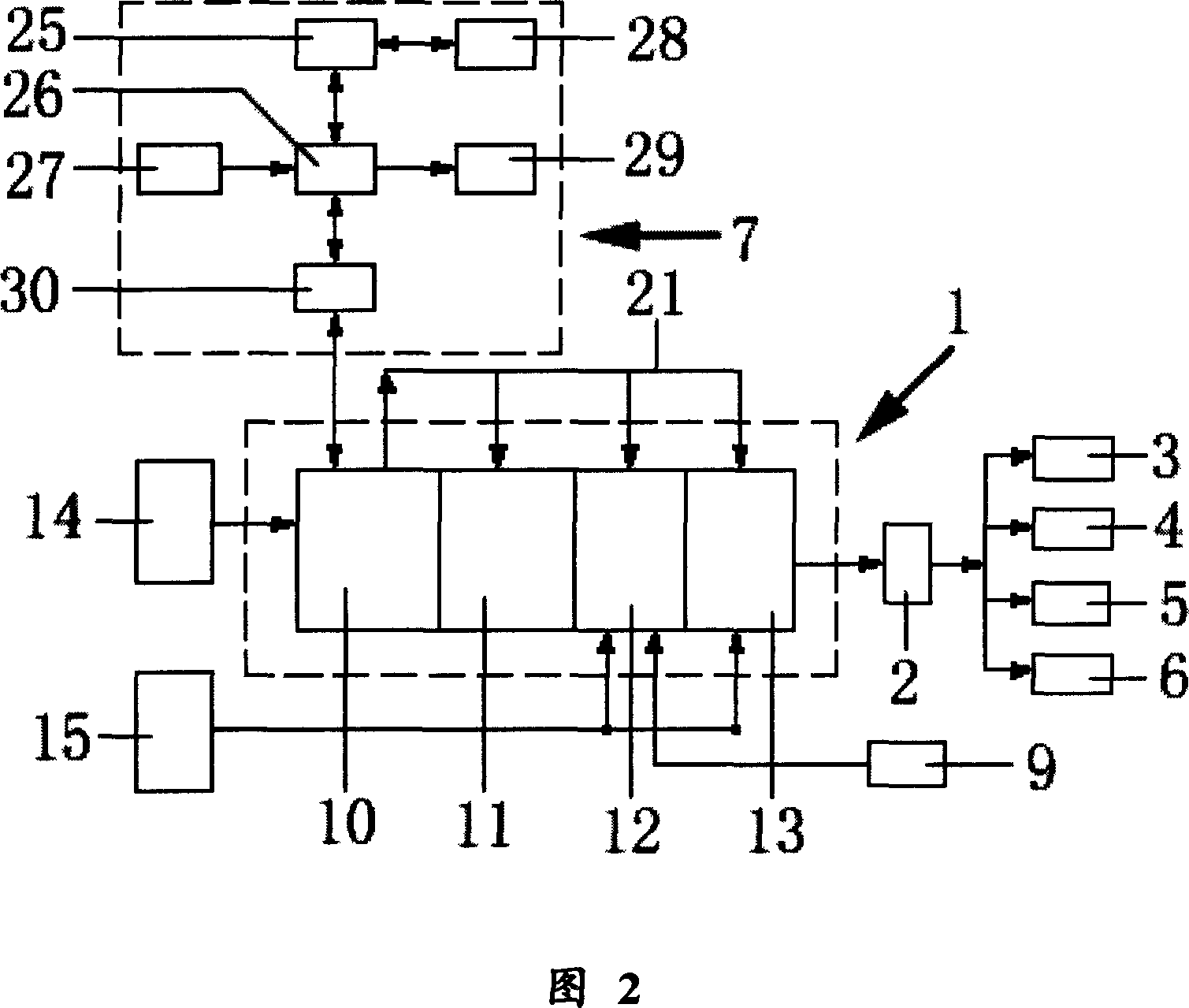

[0040] PLC main controller (1) is made up of main control module (10), communication conversion module (11), AI module (12) and DO module (13), main control module (10), communication conversion module (11), The AI module (12) and the DO module (13) are connected through the interface of the PLC backplane, and communicate with each other. The main control module (10) adopts the S16-M1 module, which supports wired and wireless communication, and the real-time clock provides daily operation. and the alarm time, the communication conversion module (11) adopts the F204 template, the AI module (12) adopts the F101 module, the input end is connected with the high-precision analog signal source of the pressure, liquid level, flow and temperature transmitters, and the DO module (13) F133 module is used to control indicator lights, relays, valves and other ON / OFF devices that require 12-24VDC and appropriate load current.

[0041] The AI module (12) of the PLC main controller (1)...

Embodiment 2

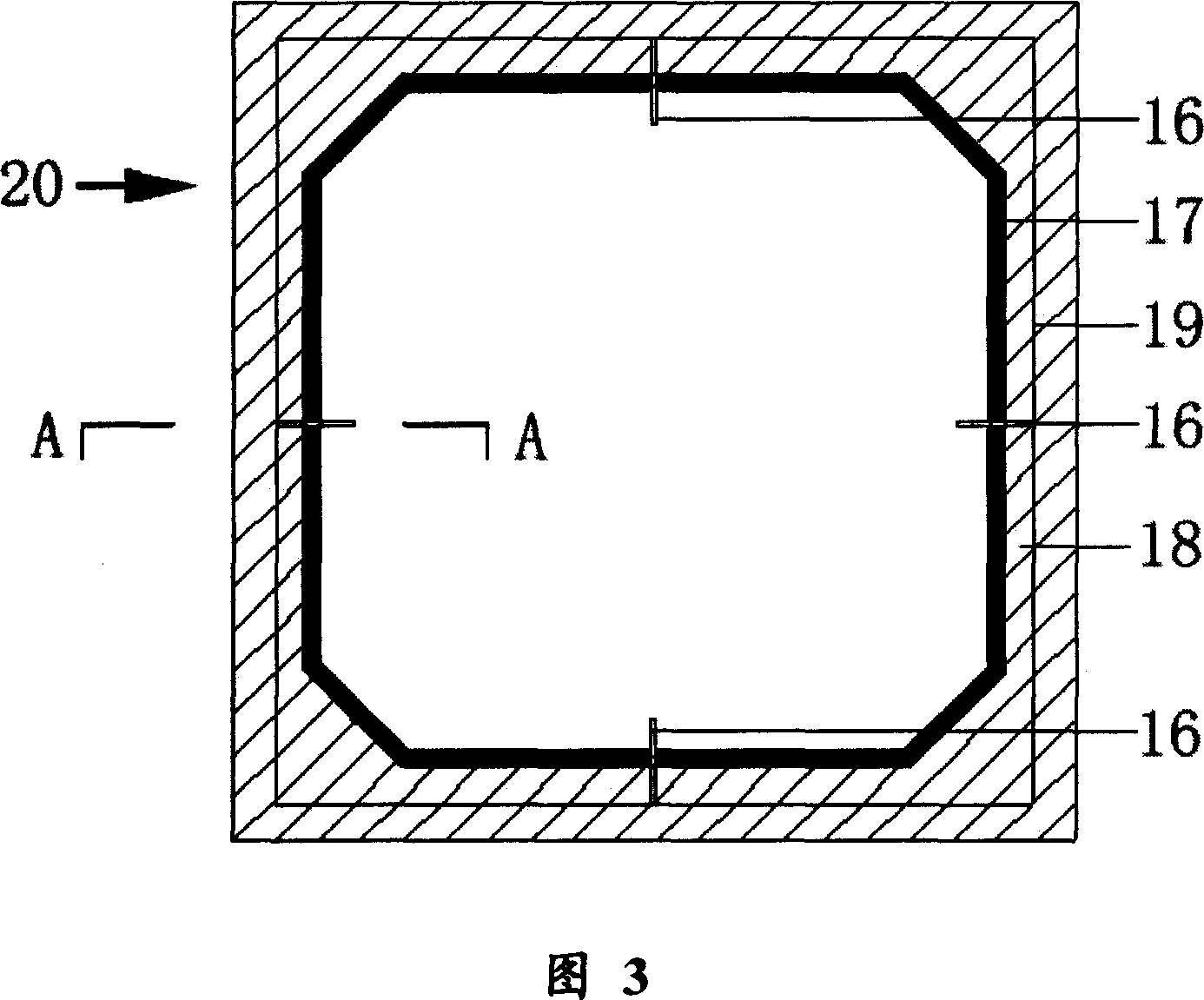

[0049] The sealant adopts polyurethane sealant, the airtight layer (17) adopts two-component polysulfide sealant material to make the airtight layer (17), the filling layer (18) adopts the foam plastic plate material to make the filling layer (18), and the water-stop airtight layer ( 19) The water-stop sealing layer (19) is made of rubber water-stop material, as shown in Fig. 3 and Fig. 4 .

Embodiment 3

[0051] Before making the airtight layer (17) of the concrete box culvert (20) expansion joint (24) or after making the airtight layer (17), use an electric drill on the expansion joint (24) from the inside of the concrete box culvert (20) to the concrete box Culvert (20) outside bores, drills more than 1 hole at least on expansion joint (24), and borehole is drilled to the water-stop airtight layer (19) of expansion joint (24). Insert the detection cannula (16) into the hole, the other end of the detection cannula (16) is inserted into the filling layer (18) through the airtight layer (17) of the expansion joint (24), and the other end of the detection cannula (16) One end is inserted into the water-stop airtight layer (19) of expansion joint (24), and the insertion opening on the airtight layer (17) around the sealing layer (17) of detection intubate (16) one end is detected with sealant bonding, detects after the sealant coagulates.

[0052] During inflation detection, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com