Method and apparatus for preventing band-steel electrolyzing cleaner running from offset and coiling leakage

An electrolytic cleaning and unit technology, which is applied in the directions of electrolytic components, transportation and packaging, and electrolytic processes, can solve problems such as adhesion, overflow edge crushing, and the next leveling unit cannot be produced normally, and achieves roughness optimization, The effect of preventing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

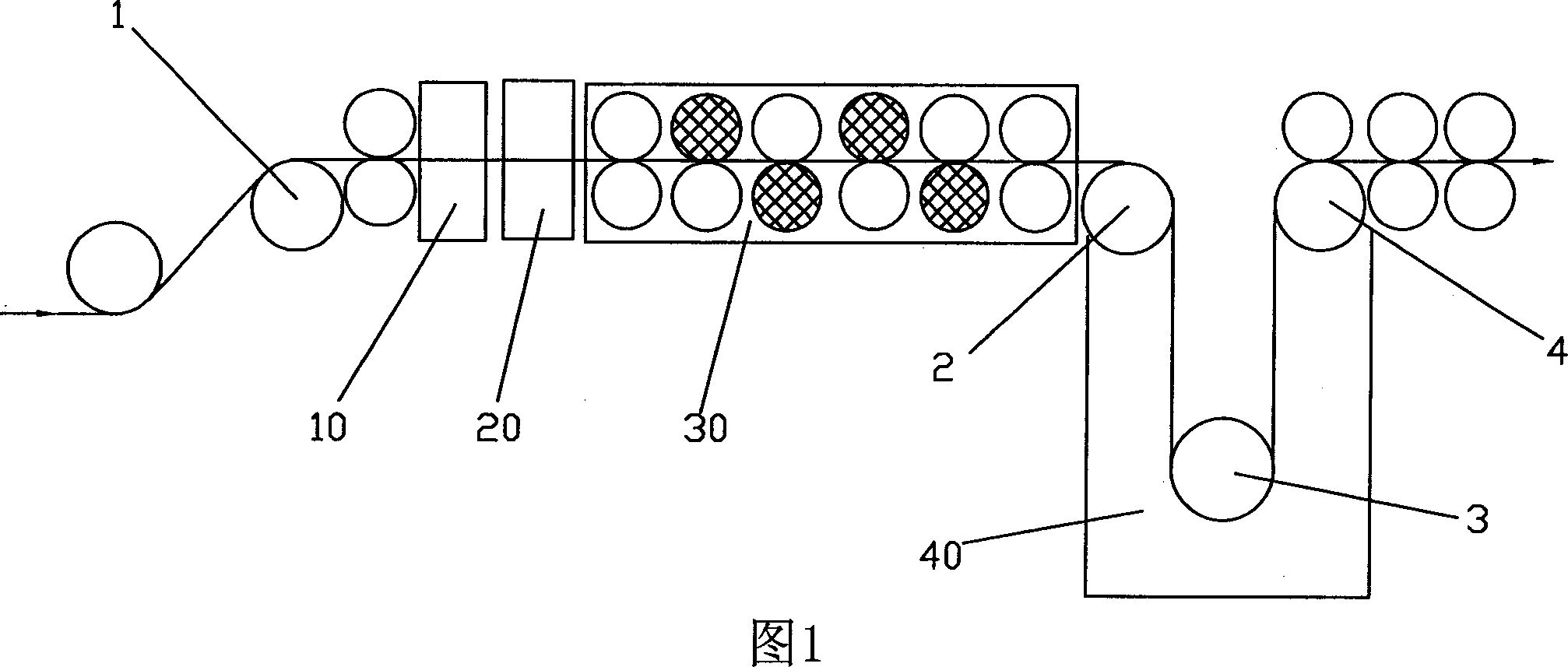

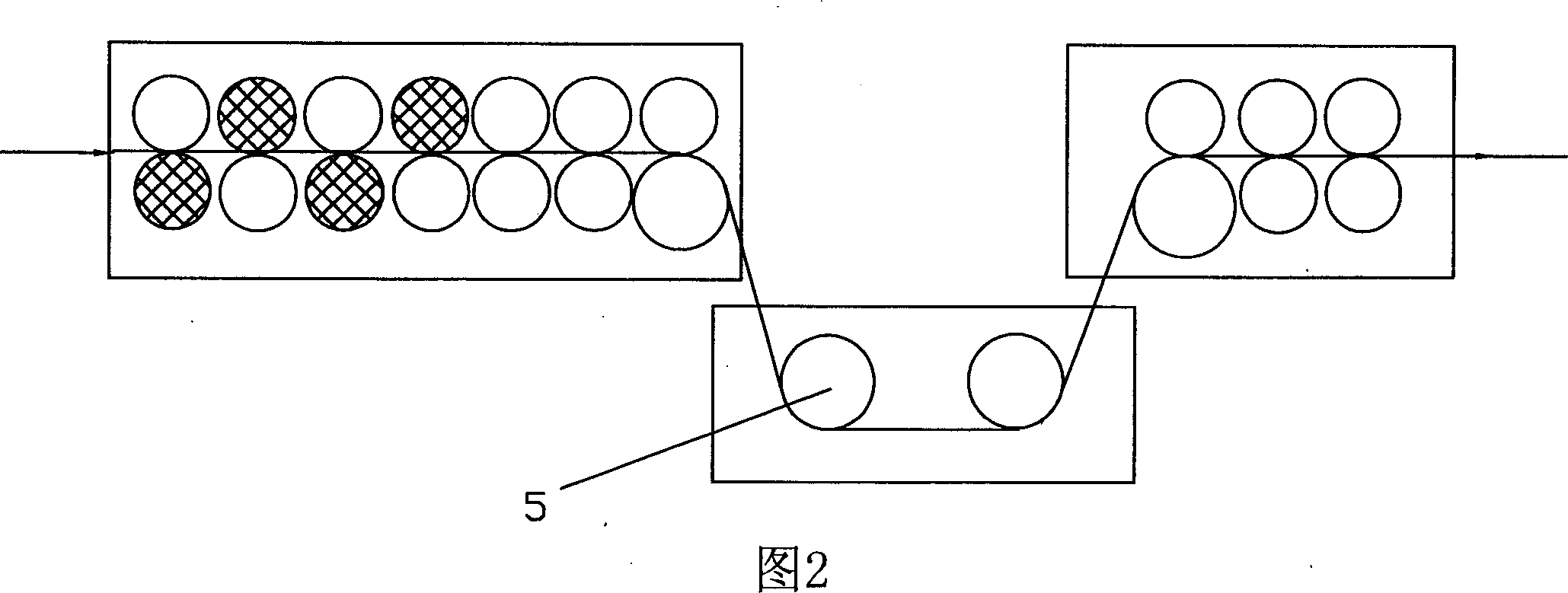

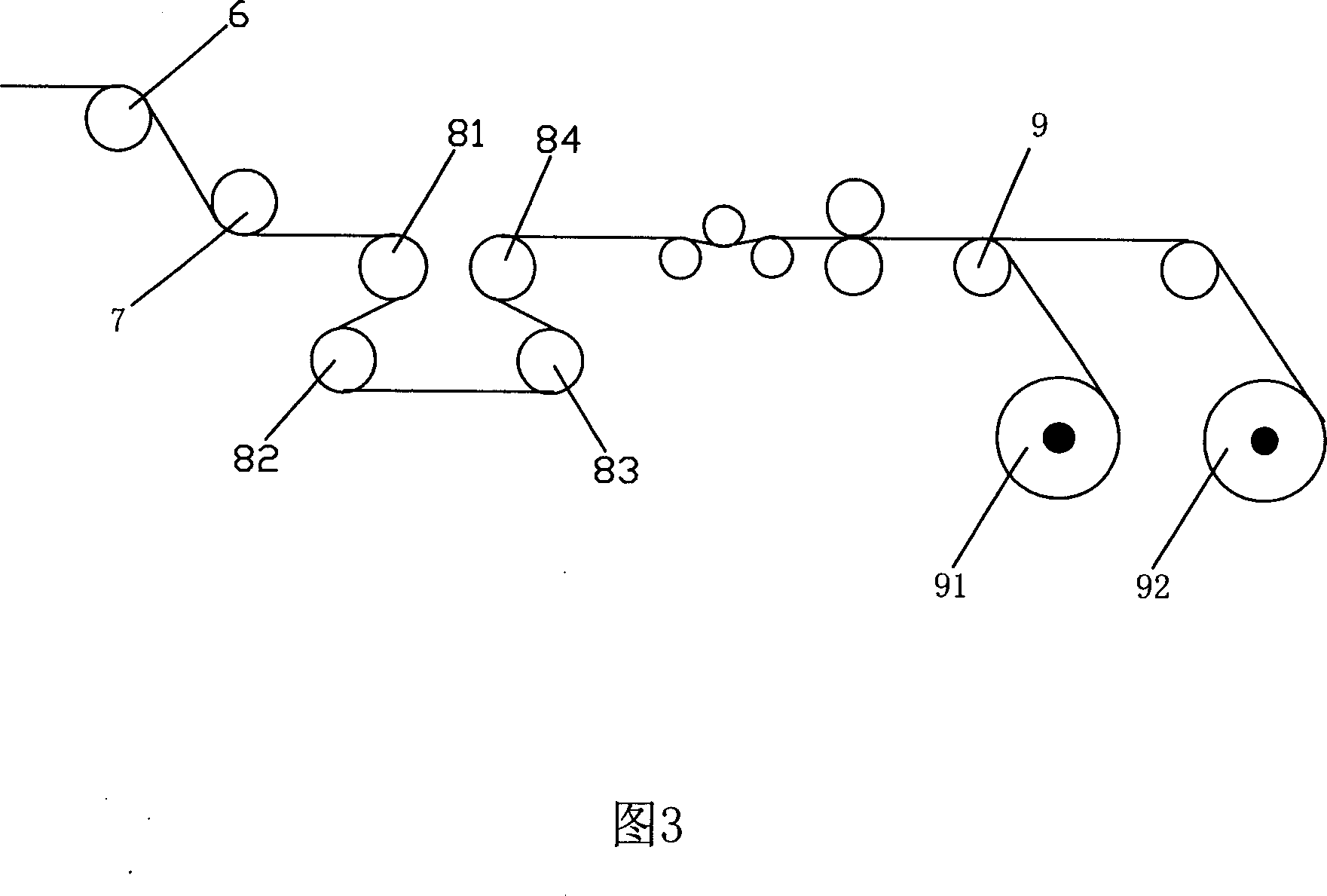

[0061] Referring to Figures 1 to 3, the method for preventing deviation and coil overflow of the electrolytic cleaning unit of the strip steel of the present invention when running at high speed, the electrolytic cleaning unit of the strip steel consists of a roll system such as an uncoiling section, a process cleaning section, and a tension coiling section. Among them, the process cleaning section includes a pre-cleaning tank, a silicon coating tank, a scrubbing tank and a rinsing tank, in which the entrance grounding roll 1, the front steering roll 2 of the immersion roll, the immersion roll 3 of the silicon coating tank, and the rear steering roll of the immersion roll of the silicon coating tank are arranged in sequence. 4. Rinsing immersion roll 5 (two); the tension coiling section includes the exit grounding roll 6 of the process cleaning section, the rear steering roll 7 after the grounding roll, tension rolls 81-84, and the front steering roll 9 of the coiler (two);

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com