Closed-circuit method for improving refractory gold ore concentrate quality and recovery rate

A gold concentrate and recovery rate technology, applied in flotation, solid separation, etc., can solve the problems of few industrial applications, limited sources, difficult treatment, etc., and achieve the effects of good selectivity, wide sources, high grade and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

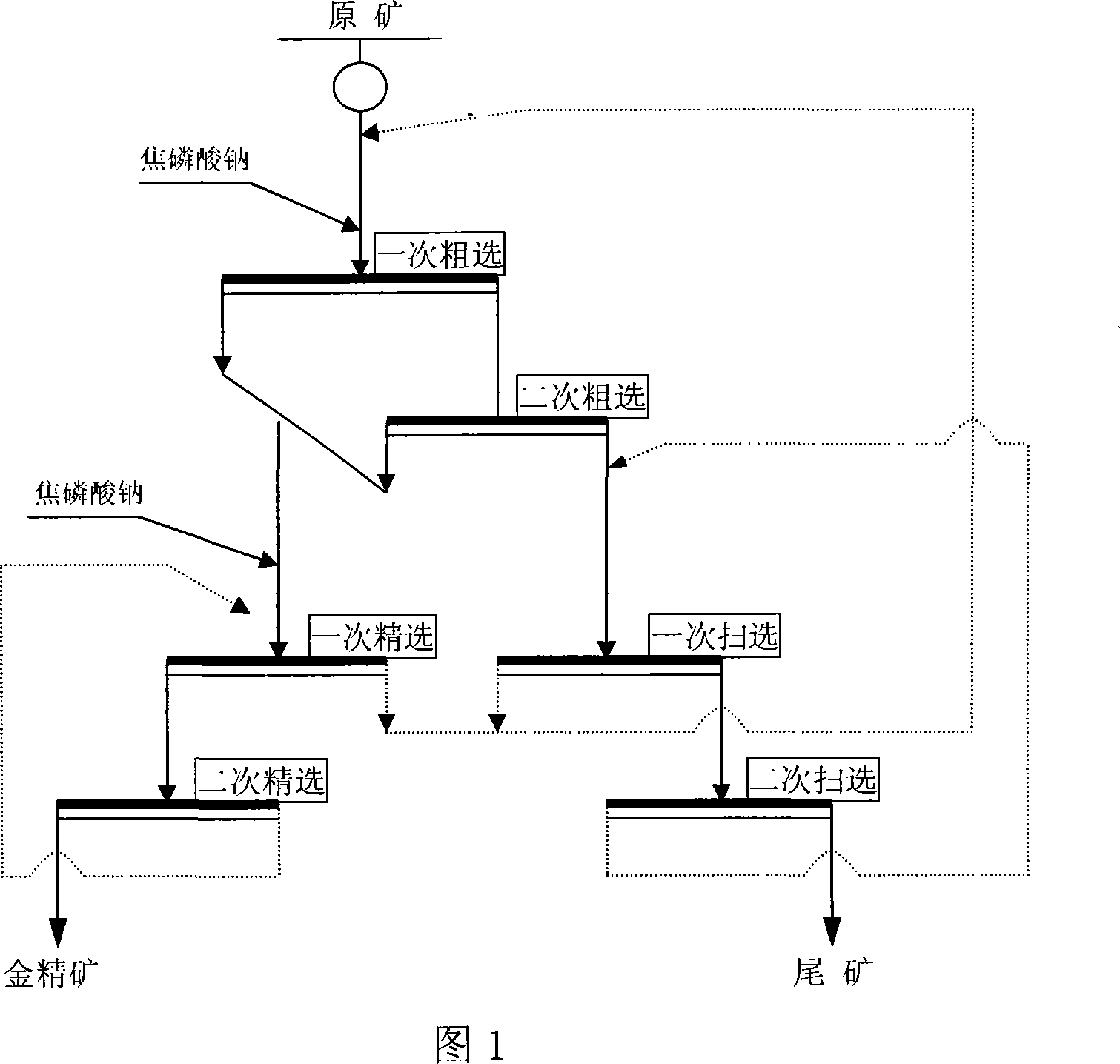

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

[0020] To realize this closed-circuit method for improving the grade and recovery rate of gold concentrate of refractory gold mines is to add sodium pyrophosphate respectively in a roughing and a beneficiation process, which specifically includes the following steps:

[0021] (1) Change the molecular formula to Na 4 P 2 o 7 10H 2 O powdery or granular sodium pyrophosphate and raw ore are dissolved in water at 0.1-0.3% by weight to form an aqueous solution of sodium pyrophosphate;

[0022] (2) primary roughing, the sodium pyrophosphate aqueous solution is added to the raw ore pulp and stirred evenly, and a primary roughing is carried out;

[0023] (3) primary concentration, the sodium pyrophosphate aqueous solution is added to the gold concentrate of primary roughing and the gold concentrate of primary roughing and secondary roughing and stir evenly, and carry out p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com