Heat transfer elastic badge

A thermal transfer and elastic technology, applied in the field of labels, which can solve the problems of difficult processing of labels, easy blurring of patterns, and inability to refine them.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

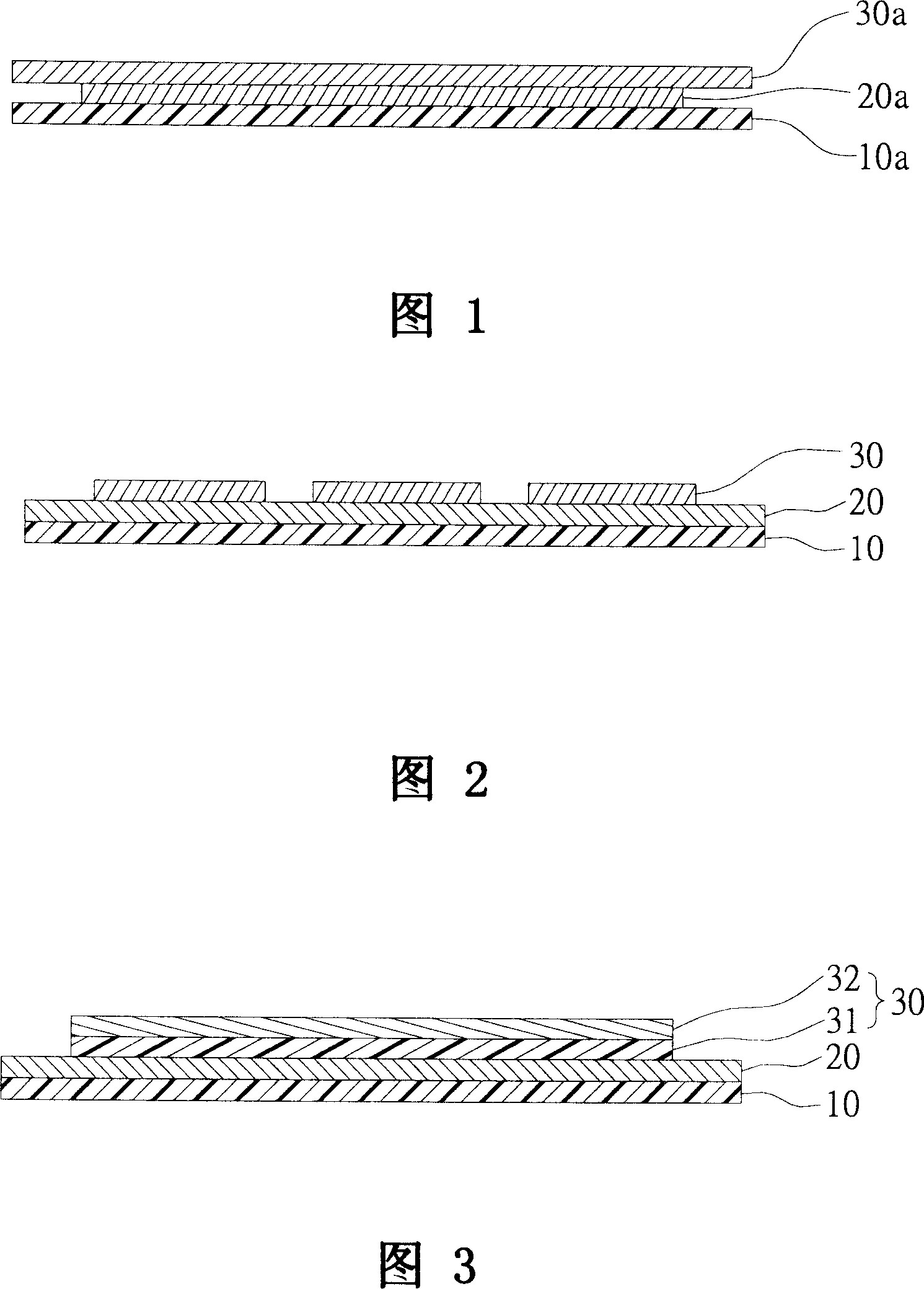

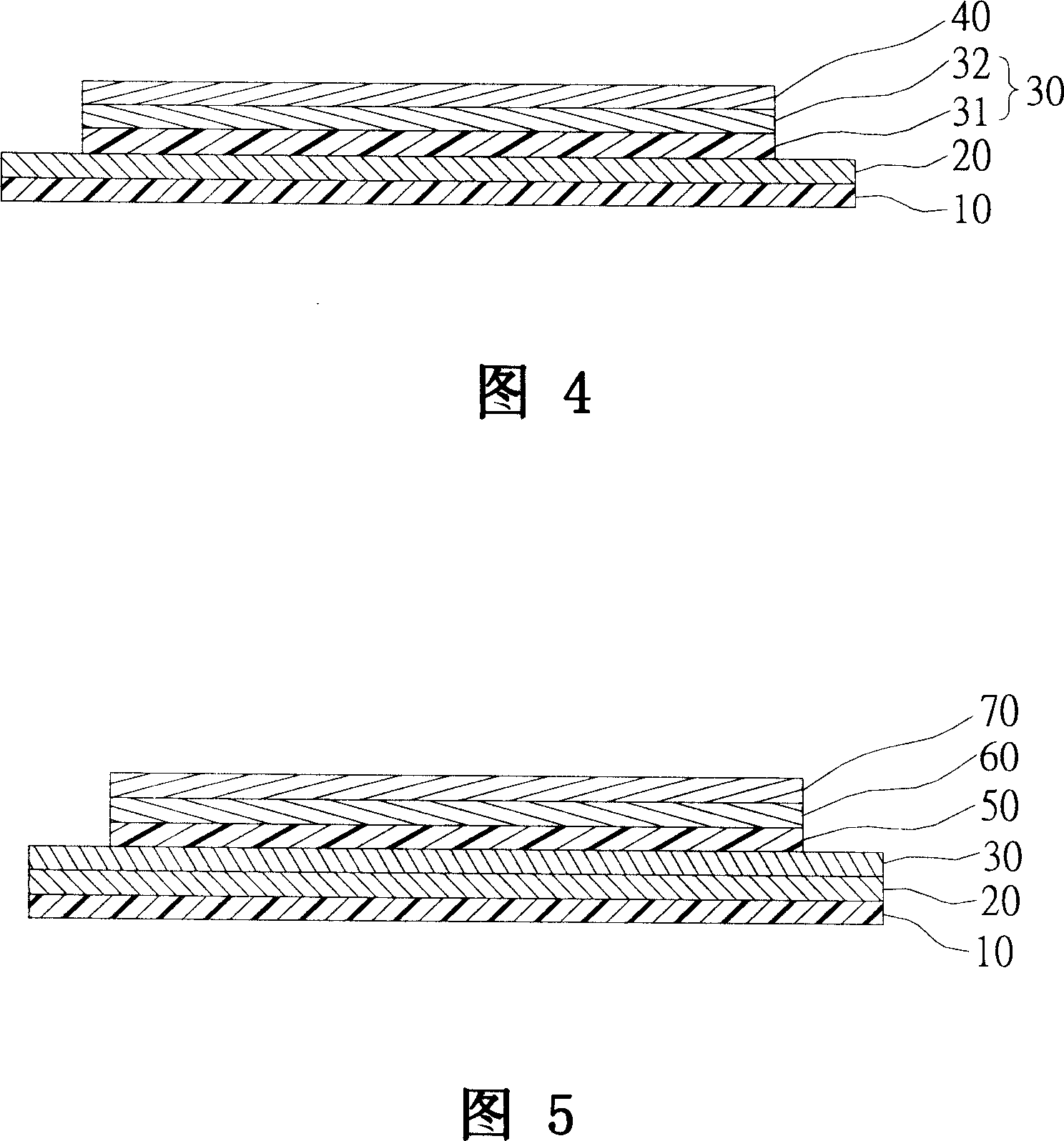

[0025] Please refer to FIG. 2 , which is a preferred embodiment of the present invention, including: an adhesive layer 10 , an elastic layer 20 and an additional layer 30 . The adhesive layer 10 is an elastic hot-melt adhesive or thermoplastic resin. The shape of the adhesive layer 10 is designed according to the required pattern shape. way, the adhesive layer 10 is melted and adhered to the surface of the printed matter.

[0026] The elastic layer 20 is made of extensible and elastic materials, such as latex, PU (polyurethan polyurethane), TPU (thermoplastic polyurethane) or silica gel, etc., which has good processability, and its thickness is about 0.05 to 2.0 Between millimeters (mm), the elastic layer 20 is fixed on the upper surface of the adhesive layer 10 in the form of a whole or multiple blocks, and the die is made according to the pre-designed pattern shape, and then the die is driven by electricity or other power and a jig, the elastic layer 20 and the adhesive lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com