Floating tail-coal graded recovering process

A technology of flotation tailing coal and process method, which is applied in the direction of solid separation, etc., can solve the problems of high viscosity, low price and high investment in infrastructure, and achieve good economic and social benefits, simple process and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

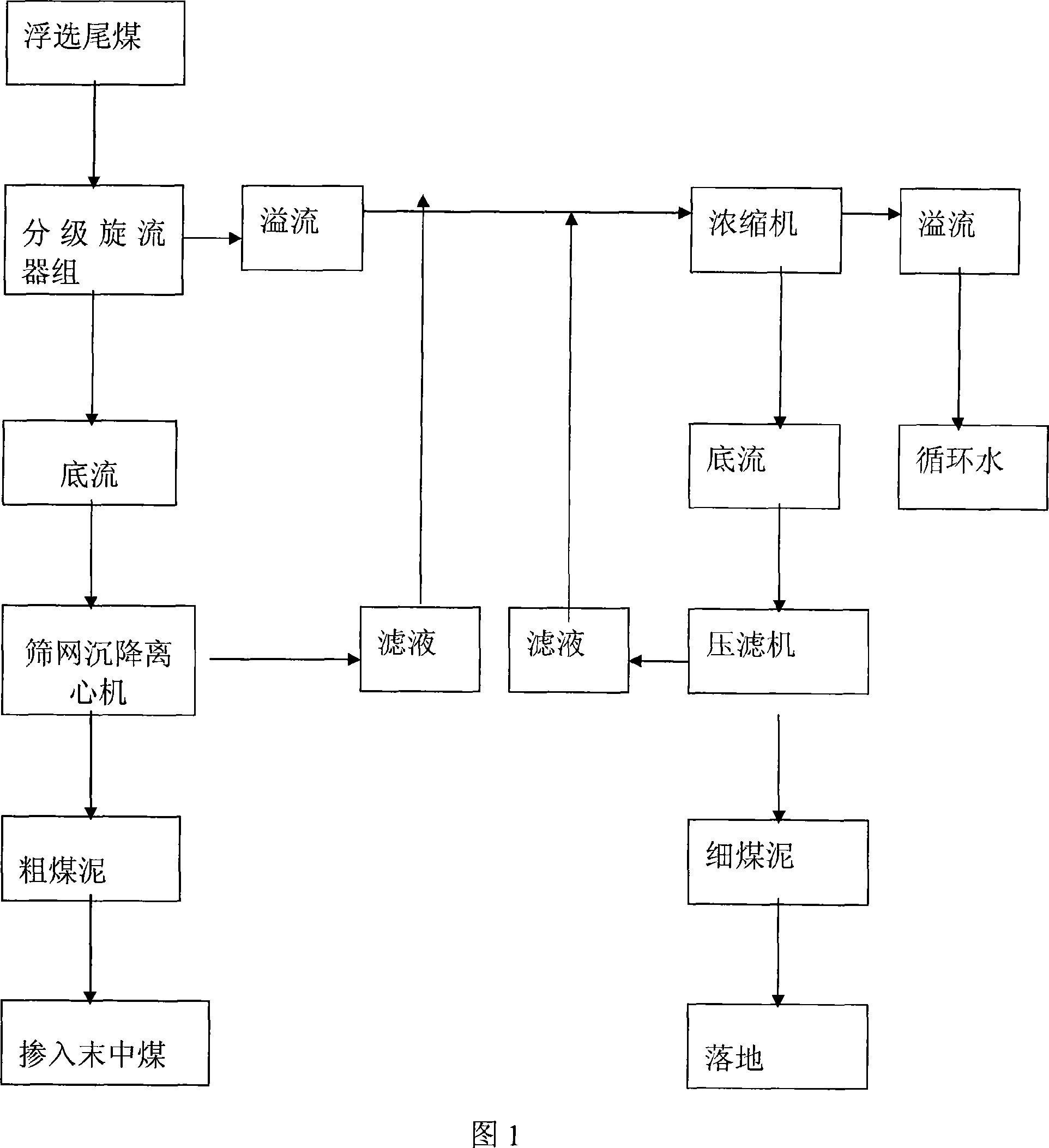

[0018] Its key point of the present invention is to carry out two-stage treatment after adopting hydrocyclone as classification by the one-stage treatment of flotation tailing coal of prior art, and the first stage mainly reclaims coarse coal slime (normally +200 order), The second section ensures the closed circuit of washing water and the concentration of circulating water. This method uses a hydrocyclone group as the classification equipment, and the particle size of the classification recovery can be adjusted according to the requirements of the first and second stages. Coarse coal slime is dehydrated by a screen decanter centrifuge, which can obtain lower moisture and be mixed with fine coal. Because most of the slime is recovered by the screen sedimentation centrifuge, only a small part of the fine slime needs to be treated by thickeners and filter presses, so the number of thickeners and filter presses is reduced, and their main function is to ensure clarified water and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com