Super-strong acid mesoporous material synthesized in one pot and preparing method

An acid-mesoporous, super-strong technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of catalyst preparation steps and long cycle, and achieve good catalytic activity and short cycle , the effect of fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0016] First, 4.4gZr(NO 3 ) 4 ·3H 2 O and 1.63gCTAB were dissolved in 40ml and 15ml of ethanol solution respectively, after dissolving, mixed and stirred for 1h, counted as A; at the same time, 1gP123 was dissolved in 10ml 1mol / LH 2 SO 4 and 30ml of 2mol / L HCl, stirred at 40°C for 3h, until P123 was completely dissolved, then added 2.3ml of TEOS, continued to stir for 2.5h, counted as B;

[0017] Then put A in a 100ml reaction kettle with a polytetrafluoroethylene liner, pre-crystallize at 110°C for 3.5h, then take it out, cool to room temperature, stir at room temperature for 0.5h, add B, continue Stir for 3 hours, put in a kettle, crystallize at 100°C for 48 hours, count as C;

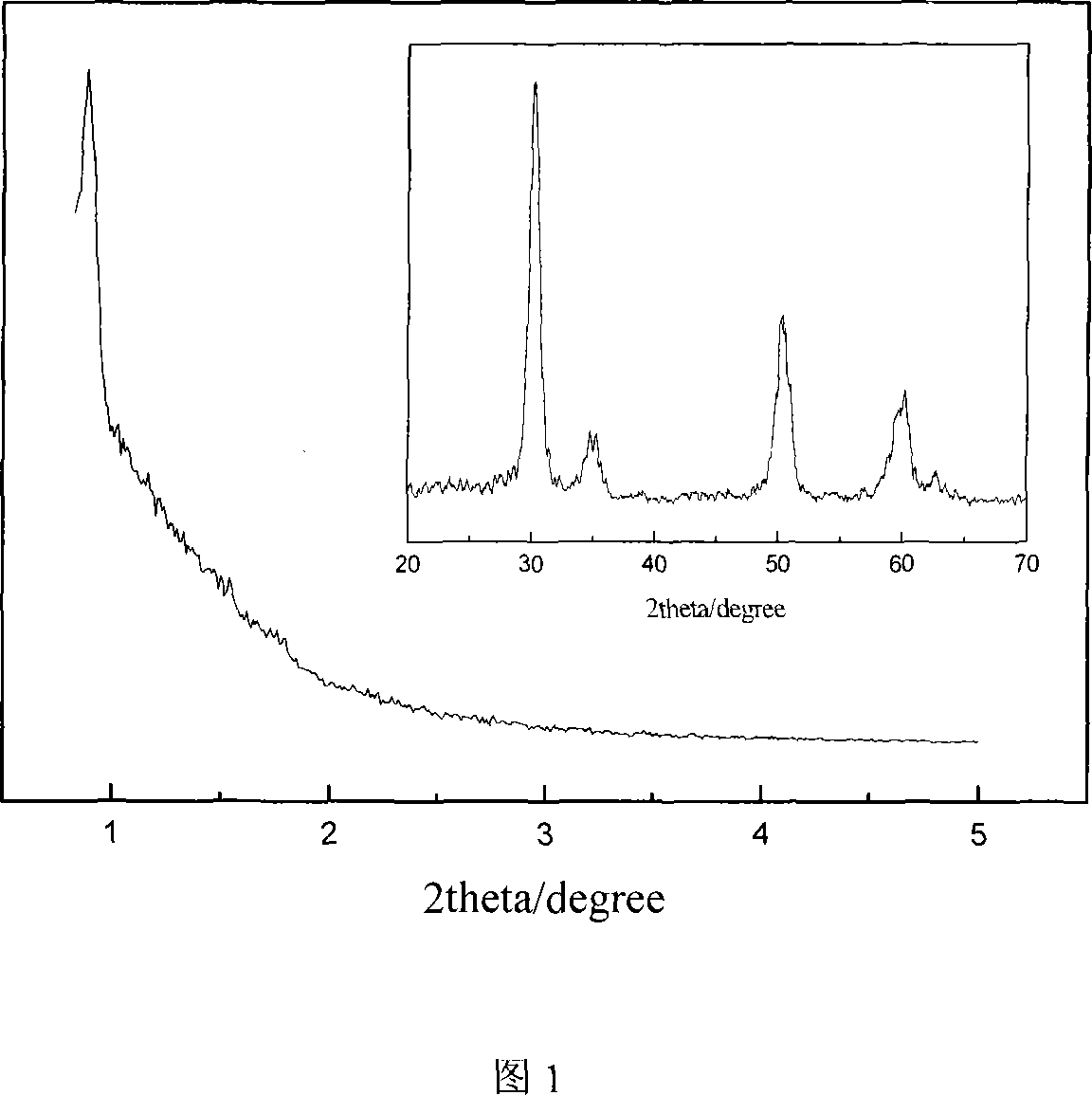

[0018] Finally, cool C, wash, filter with suction, dry at room temperature, and roast at 600°C for 3 hours to obtain SO 4 2- / ZrO 2 -SiO 2 The superacid mesoporous material has good crystallinity by XRD analysis.

Embodiment approach 2

[0020] First, 4.4gZr(NO 3 ) 4 ·3H 2 O and 1.63gCTAB were dissolved in 40ml and 15ml of ethanol solution respectively, after dissolving, mixed and stirred for 1h, counted as A; at the same time, 1gP123 was dissolved in 20ml 1mol / LH 2 SO 4 and 20ml of 2mol / L HCl, stir at 40°C for 4h, until P123 is completely dissolved, add 2.3ml of TEOS, continue to stir for 2h, count as B;

[0021] Then put A in a 100ml reaction kettle with a polytetrafluoroethylene liner, pre-crystallize at 110°C for 4h, then take it out, cool to room temperature, stir at room temperature for 0.5h, add B, and continue stirring 3h, put in a kettle, crystallize at 95°C for 48h, counted as C;

[0022] Finally, cool C, wash, suction filter, dry at room temperature, and roast at 610°C for 2.5h to obtain SO 4 2 / ZrO 2 -SiO 2 The crystallinity of the superacid mesoporous material is more than twice that of the sample obtained in the first embodiment through XRD analysis.

Embodiment approach 3

[0024] First, 4.4gZr(NO 3 ) 4 ·3H 2 O and 1.63gCTAB were dissolved in 40ml and 15ml of ethanol solution respectively, after dissolving, mixed and stirred for 1h, counted as A; at the same time, 1gP123 was dissolved in 30ml 1mol / LH 2 SO4 and 10ml of 2mol / L HCl, stir at 38°C for 3.5h, until P123 is completely dissolved, add 2.3ml of TEOS, continue to stir for 3h, count as B;

[0025] Then put A in a 100ml reaction kettle with a polytetrafluoroethylene liner, pre-crystallize at 115°C for 3h, then take it out, cool to room temperature, stir at room temperature for 0.5h, add B, and continue stirring 3h, put in a kettle, crystallize at 100°C for 46h, count as C;

[0026] Finally, cool C, wash, filter with suction, dry at room temperature, and roast at 590°C for 3.5h to obtain SO 4 2- / ZrO 2 -SiO 2 Superacid mesoporous materials. According to XRD analysis, its crystallinity is more than double that of the sample obtained in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com