Crawler crane torque controlling method and apparatus under super lifting working condition

A technology of crawler cranes and cranes, applied in torque/mechanical power control, non-electric variable control, control/regulation systems, etc., can solve problems such as unprecedented and unlimited rear overturning moments, and the method is novel and easy to implement , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The control method of the present invention and the structure of the device for realizing the method will be further described below in conjunction with the accompanying drawings.

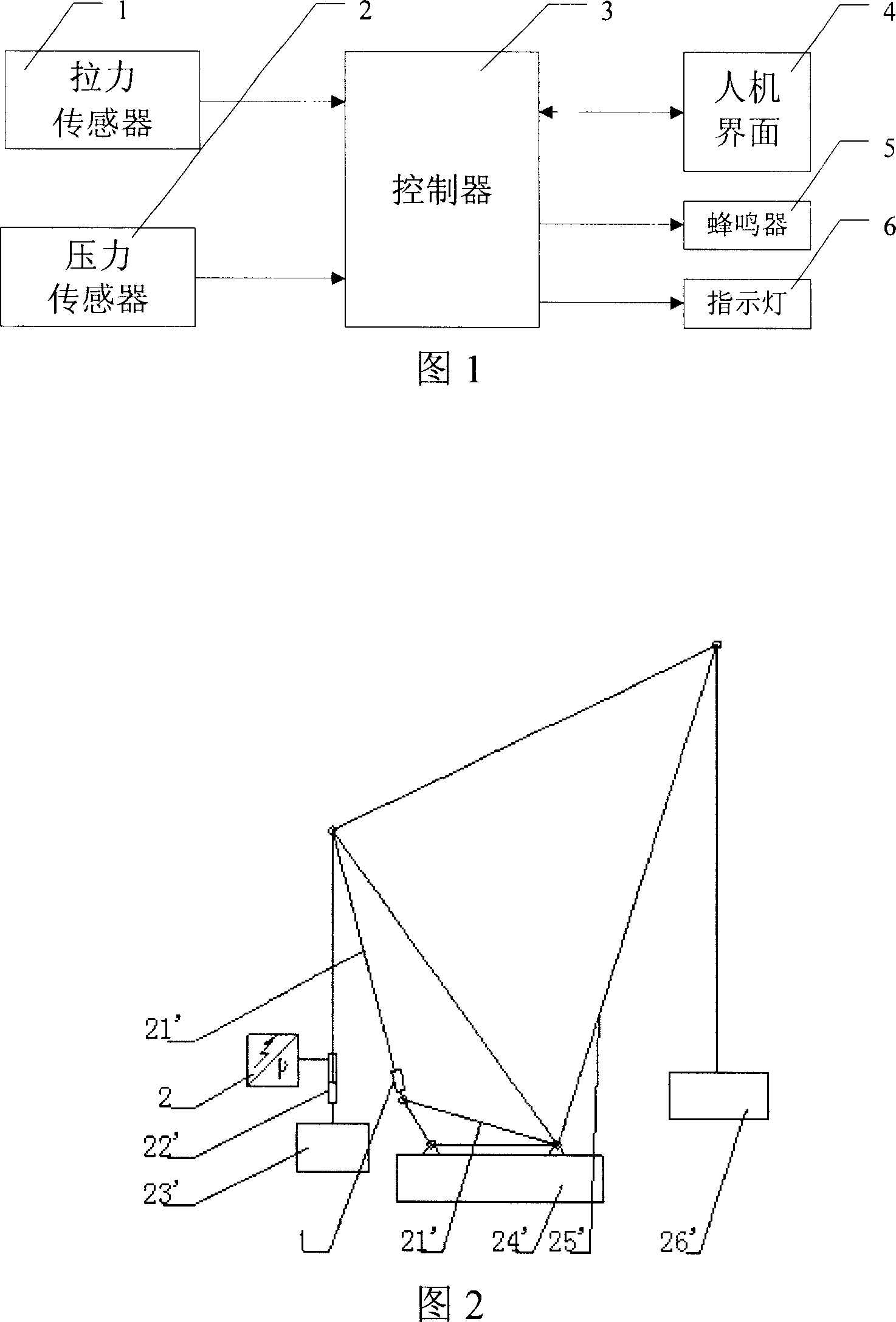

[0032] Fig. 1 is the structure schematic diagram of the device of the present invention, as shown in Fig. 1, comprise buzzer 5 and indicator light 6, be placed on the tension sensor 1 on the main luffing pull rod of crane, be placed on the pressure on the lifting oil cylinder of super lifting counterweight The sensor 2, the controller 3 coupled with the buzzer 5, the indicator light 6, the tension sensor 1 and the pressure sensor 2, and the man-machine interface 4 coupled with the controller 3. Controller 3 is a central processing unit (CPU)

[0033] The tension sensor 1 is installed on the main luffing rod, and its signal output terminal is connected with the analog quantity input terminal of the controller 3; The input terminal is coupled to detect the pressure of the counterweight oil cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com