Integrated photon crystal double waveguide back coupling fluid refractive index sensor

A technology of refractive index sensor and photonic crystal, which is applied in the field of integrated optoelectronics, can solve the problems of high noise, cannot be integrated in plane, and is difficult to use, and achieves the effect of high sensitivity characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

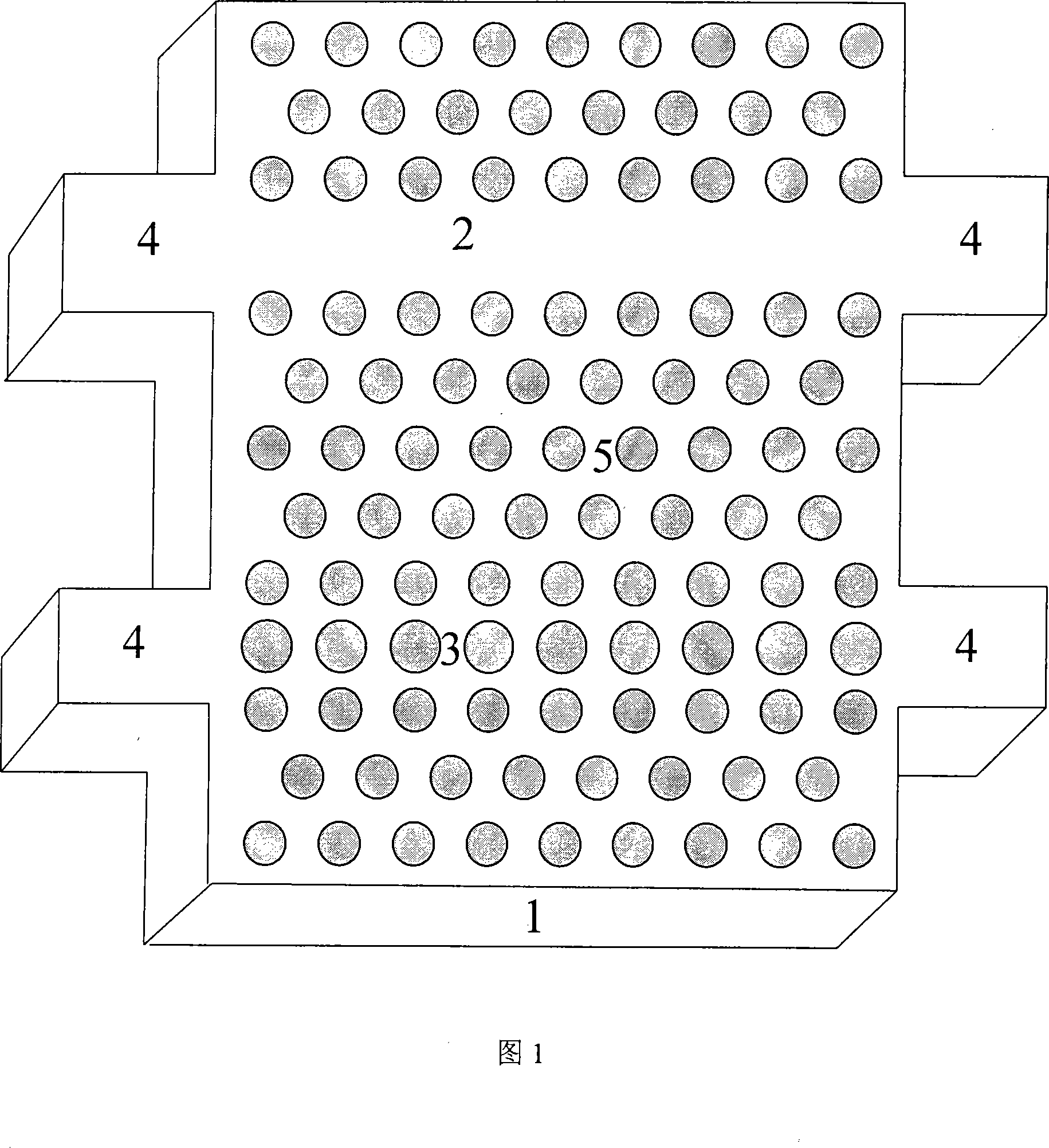

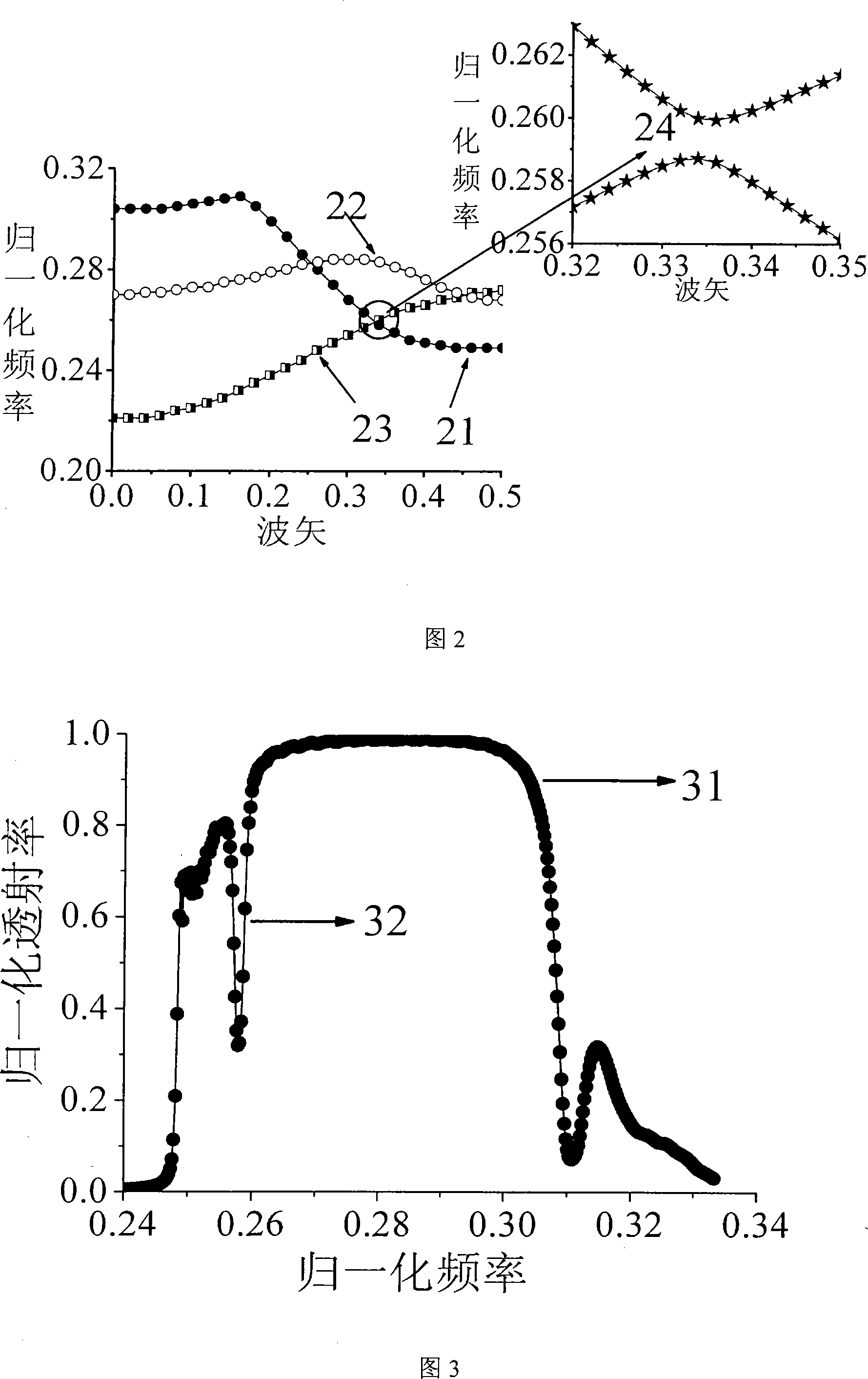

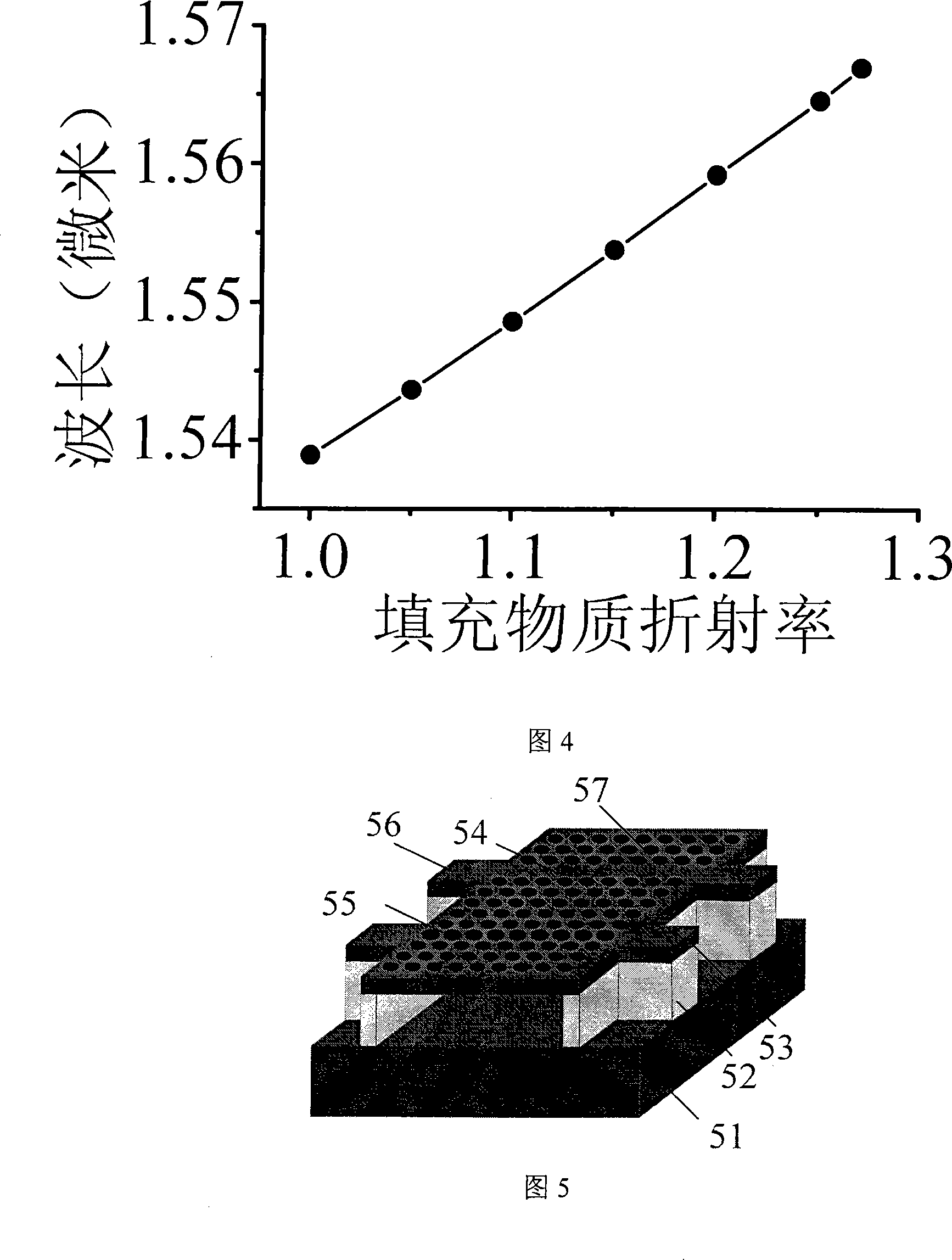

[0030] The structure of the fluid refractive index sensor based on photonic crystal dual-waveguide reverse coupling that can be integrated with the light source of the present invention is shown in FIG. 5 . Select Si-SiO 2 -SOI substrate wafer made of Si, in which SiO 2 The layer thickness is 2 μm, and the upper Si thickness is 220 nm. The connecting waveguide 56 and the 2-dimensional photonic crystal periodic hole structure 57 are fabricated on the uppermost Si plate 53 by electron beam exposure and dry etching, and a double waveguide structure 54, 55 is formed. Removal of a portion of SiO by selective wet etching 2 layer, leaving the SiO 2 The layer is the bridge support structure 52 . When the light field introduced by the connecting waveguide 56 passes through the through-waveguide 54, due to the reverse coupling effect with the coupling waveguide 55, the transmission spectrum shown in Figure 3 will be observed at the output connecting waveguide, and the transmission s...

Embodiment 2

[0032]The structure of the fluid refractive index sensor based on photonic crystal dual-waveguide reverse coupling that can be integrated with the light source of the present invention is shown in FIG. 6 . A substrate 61 of GaAs material is selected, and a 2 μm AlGaInP sacrificial layer and a 220 nm GaAs waveguide layer are grown thereon. Electron beam exposure and dry etching are used to fabricate a connecting waveguide 66 and a 2-dimensional photonic crystal periodic hole structure 67 on the uppermost GaAs slab 63 to form dual waveguide structures 64 and 65 . Part of the AlGaInP layer is removed by selective wet etching, and the remaining AlGaInP layer is the bridge support structure 62 . When the light field introduced by the connecting waveguide 66 passes through the straight-through waveguide 64, due to the reverse coupling effect with the coupling waveguide 65, the transmission spectrum shown in Figure 3 will be observed at the output connecting waveguide, and the transm...

Embodiment 3

[0034] The structure of the fluid refractive index sensor based on photonic crystal dual-waveguide reverse coupling that can be integrated with the light source of the present invention is shown in FIG. 7 . A substrate 71 of InP material is selected, and a 2 μm InGaAsP sacrificial layer and a 220 nm InP waveguide layer are grown thereon. The connecting waveguide 76 and the 2-dimensional photonic crystal periodic hole structure 77 are fabricated on the uppermost InP plate 73 by electron beam exposure and dry etching, and a double waveguide structure 74, 75 is formed. A part of the InGaAsP layer is removed by selective wet etching, and the remaining InGaAsP layer is the bridge support structure 72 . When the light field introduced by the connecting waveguide 76 passes through the through-waveguide 74, due to the reverse coupling effect with the coupling waveguide 75, the transmission spectrum shown in Figure 3 will be observed at the output connecting waveguide, and the transmis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com