Vehicle braking hub

A technology of automobile brakes and brake hubs, which is applied in the field of auto parts and can solve problems such as easy breakage, potential safety hazards, and impact on service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

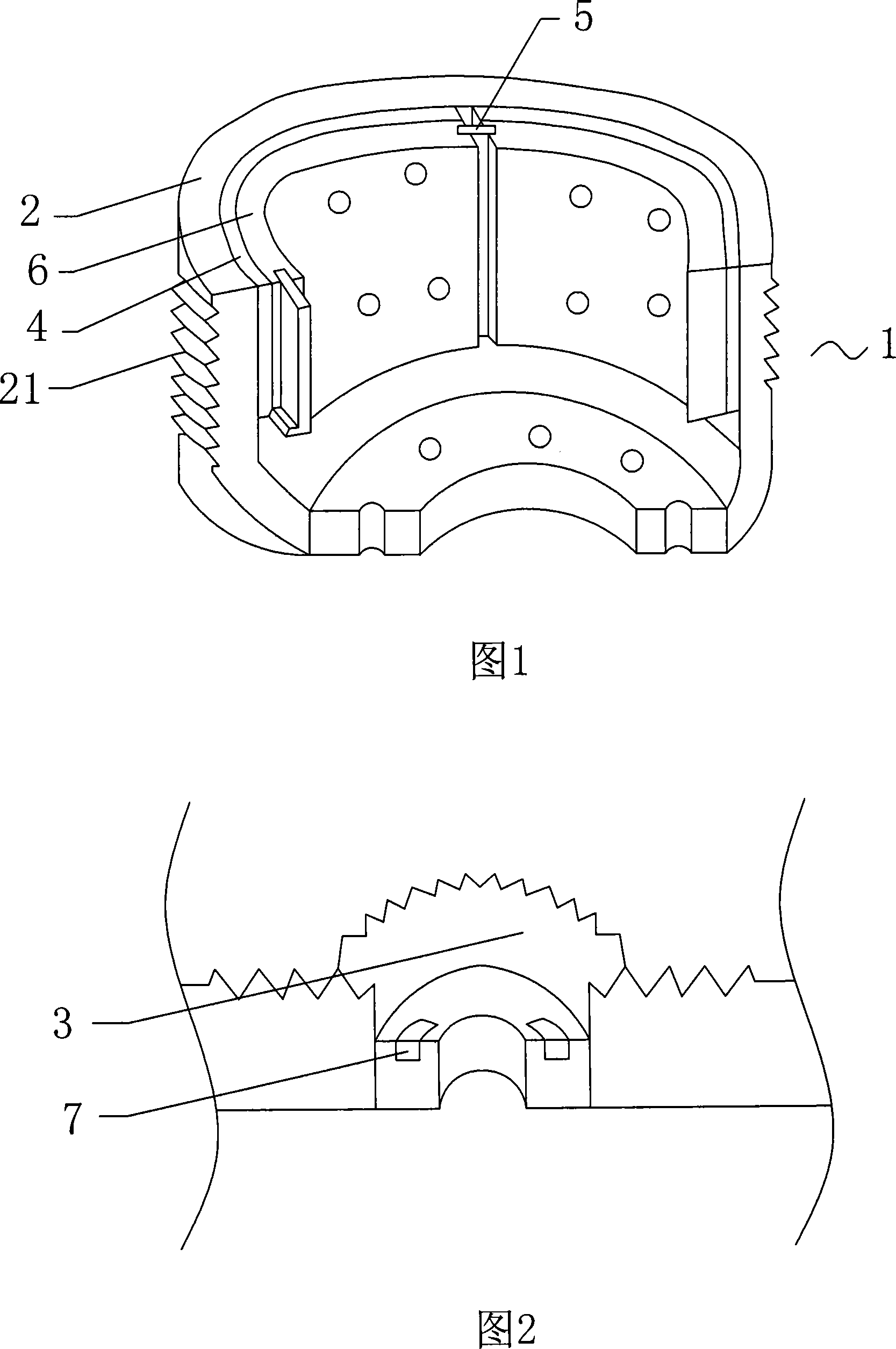

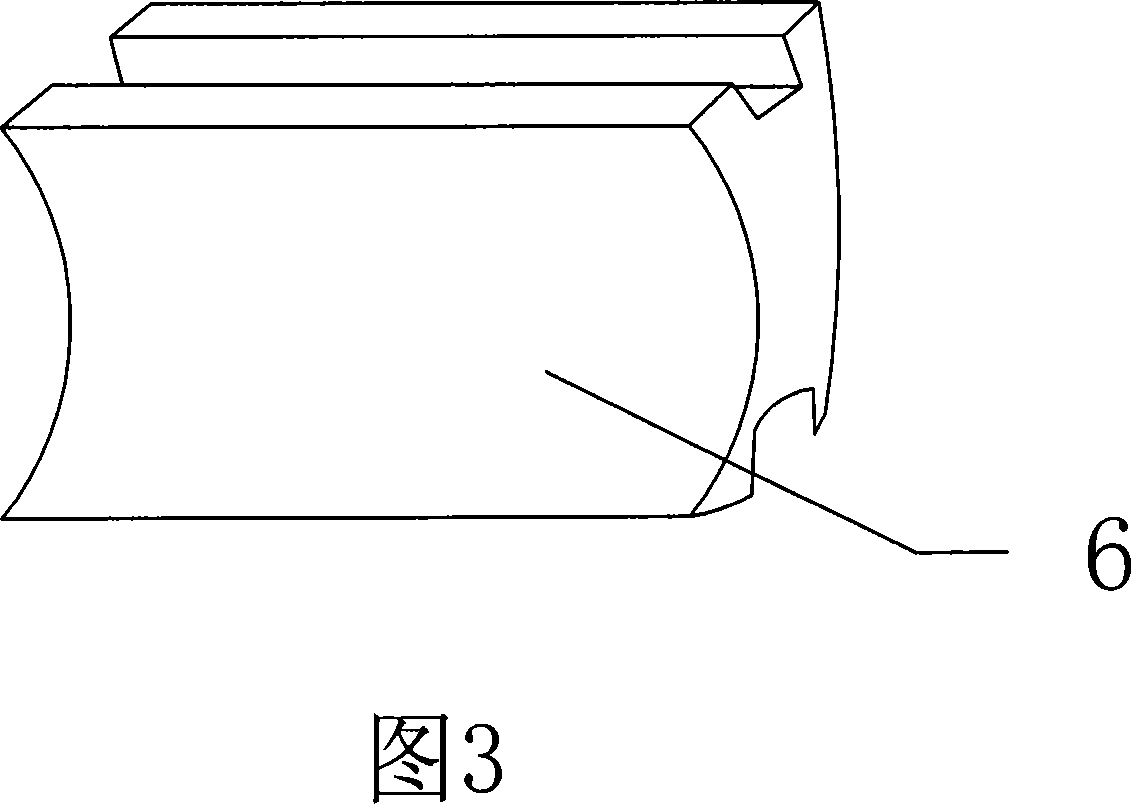

[0016] As shown in Fig. 1, it is the structural representation of the automobile brake hub of the present invention. An automobile brake hub includes a brake hub 1 . The brake hub 1 is composed of a high-strength cylindrical outer cast iron 2 and several semi-arc inner cast irons 6, as shown in Fig. The radians are matched, and the semi-arc inner cast iron 6 is fixedly installed on the inner surface of the cylindrical outer cast iron 2, that is, a through hole 3 is opened on the cylindrical outer cast iron 2, as shown in Figure 2, and the semi-arc inner cast iron 6 There are through holes 3 correspondingly matched with it, and screws are installed in the through holes 3 of the above-mentioned corresponding cylindrical outer cast iron 2 and semi-arc inner cast iron 6 to fixedly connect the cylindrical outer cast iron 2 and the semi-arc inner cast iron. cast iron6. The technical solution also includes several copper spacers 4 arranged between the cylindrical outer cast iron 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com