Monocase battery voltage balance method and balancer in the charging/discharging process of the dynamic battery group

A power battery pack, charging and discharging process technology, applied to battery circuit devices, current collectors, electric vehicles, etc., can solve problems such as permanent battery damage, low terminal voltage, and unbalanced discharge of single cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific implementation mode 1: The method for equalizing the voltage of a single battery during the charging and discharging process of a power battery pack according to this implementation mode, the steps are as follows:

[0014] A. Measure the terminal voltage of each single cell in the battery pack separately;

[0015] B. Compare the terminal voltages of adjacent single cells;

[0016] C. When the terminal voltage of a single cell is higher than the terminal voltage of any one of the two adjacent single cells, start to discharge and lower the voltage of the single cell;

[0017] D. When the terminal voltage of the single cell is lower than the terminal voltage of the two adjacent single cells, stop discharging and lowering the voltage of the single cell.

[0018] The method for equalizing the voltage of individual cells in the charging and discharging process of the power battery pack in this embodiment can keep the consistency of the terminal voltages of the indiv...

specific Embodiment approach 2

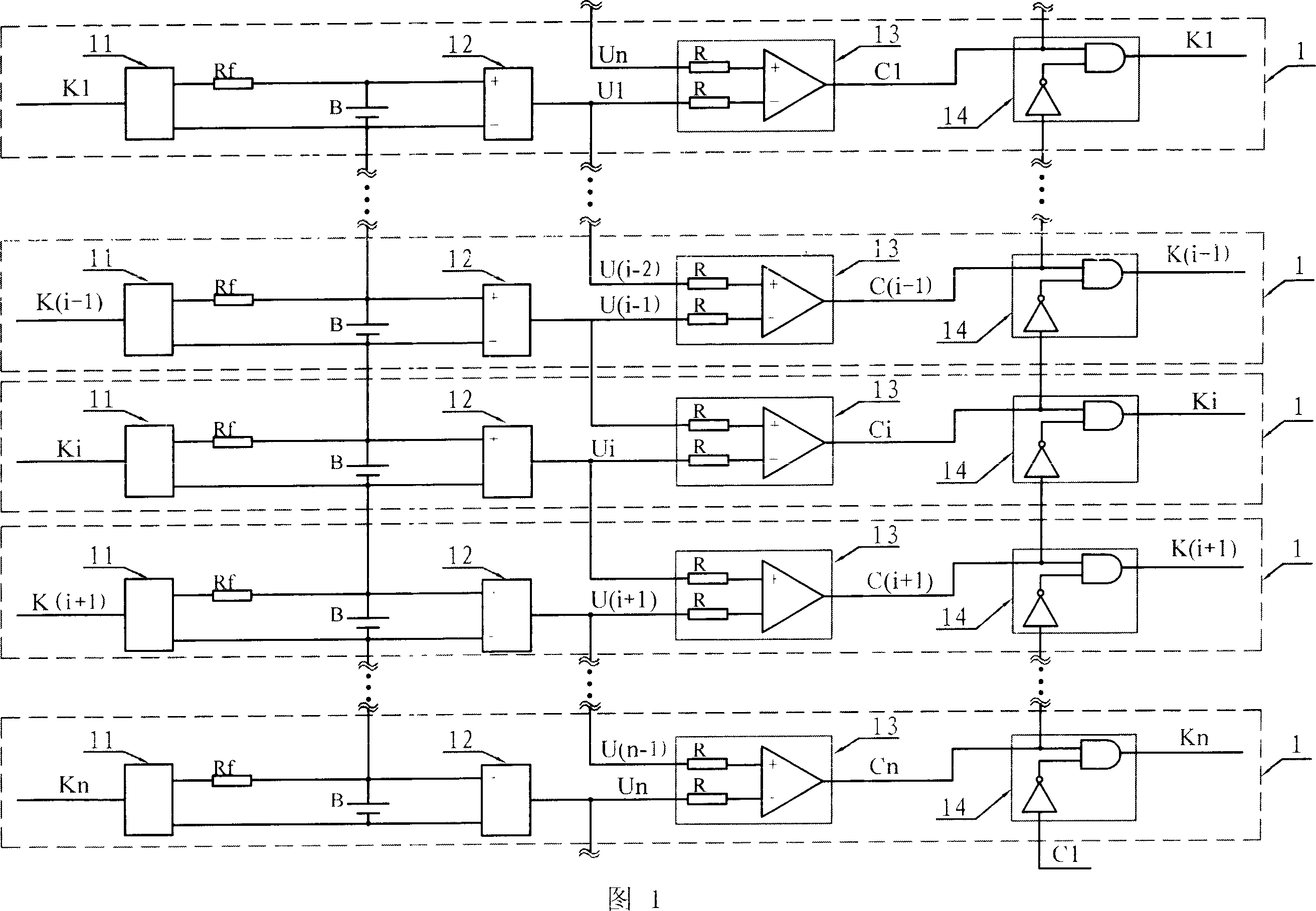

[0019] Specific embodiment 2: Refer to Fig. 1 to illustrate this embodiment, which is used to realize the single cell voltage equalization method in the power battery pack charging and discharging process described in the specific embodiment 1 during the charging and discharging process of the power battery pack The device is composed of n discharge and step-down control circuits 1, and the n discharge and step-down control circuits 1 are respectively corresponding to each single battery B in the power battery pack. The discharge step-down control circuit 1 is composed of a discharge relay 11, a discharge resistor Rf, a voltage measurement circuit 12, a voltage comparison circuit 13 and a control circuit 14; The positive and negative terminals of the voltage measurement circuit 12 are connected to the negative input of the voltage comparison circuit 13, the output of the voltage comparison circuit 13 is connected to an input terminal of the AND gate in the control circuit 14, a...

specific Embodiment approach 3

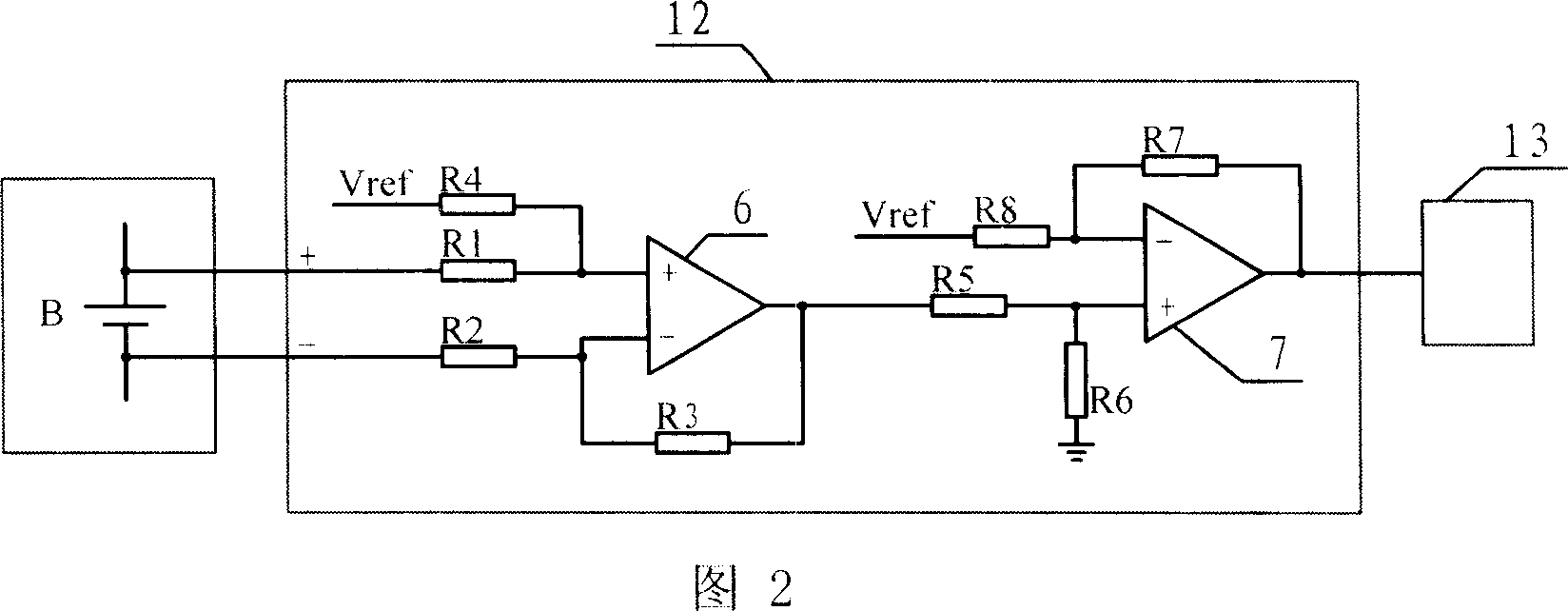

[0025] Specific embodiment three: refer to Fig. 2 to illustrate this embodiment, the voltage measuring circuit 12 described in the specific embodiment two, is made up of two-stage operational amplifier and eight resistances, the positive direction of one-stage operational amplifier 6, the negative direction input terminal The positive and negative terminals of the single battery B are respectively connected through the first resistor R1 and the second resistor R2, the positive input terminal of the first-stage operational amplifier 6 is connected with the reference voltage Vref through the fourth resistor R4, and the negative terminal of the first-stage operational amplifier 6 is connected with the reference voltage Vref through the fourth resistor R4. A primary feedback resistor R3 is connected between the input terminal and the output terminal, the output terminal of the primary operational amplifier 6 is connected to the positive input terminal of the secondary operational am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com