SOI compound covariant layer underlay with the metal Hafnium middle layer

An intermediate layer and substrate technology, applied in electrical components, electrical solid-state devices, circuits, etc., to achieve the effect of facilitating realization, improving growth quality, and superior optoelectronic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

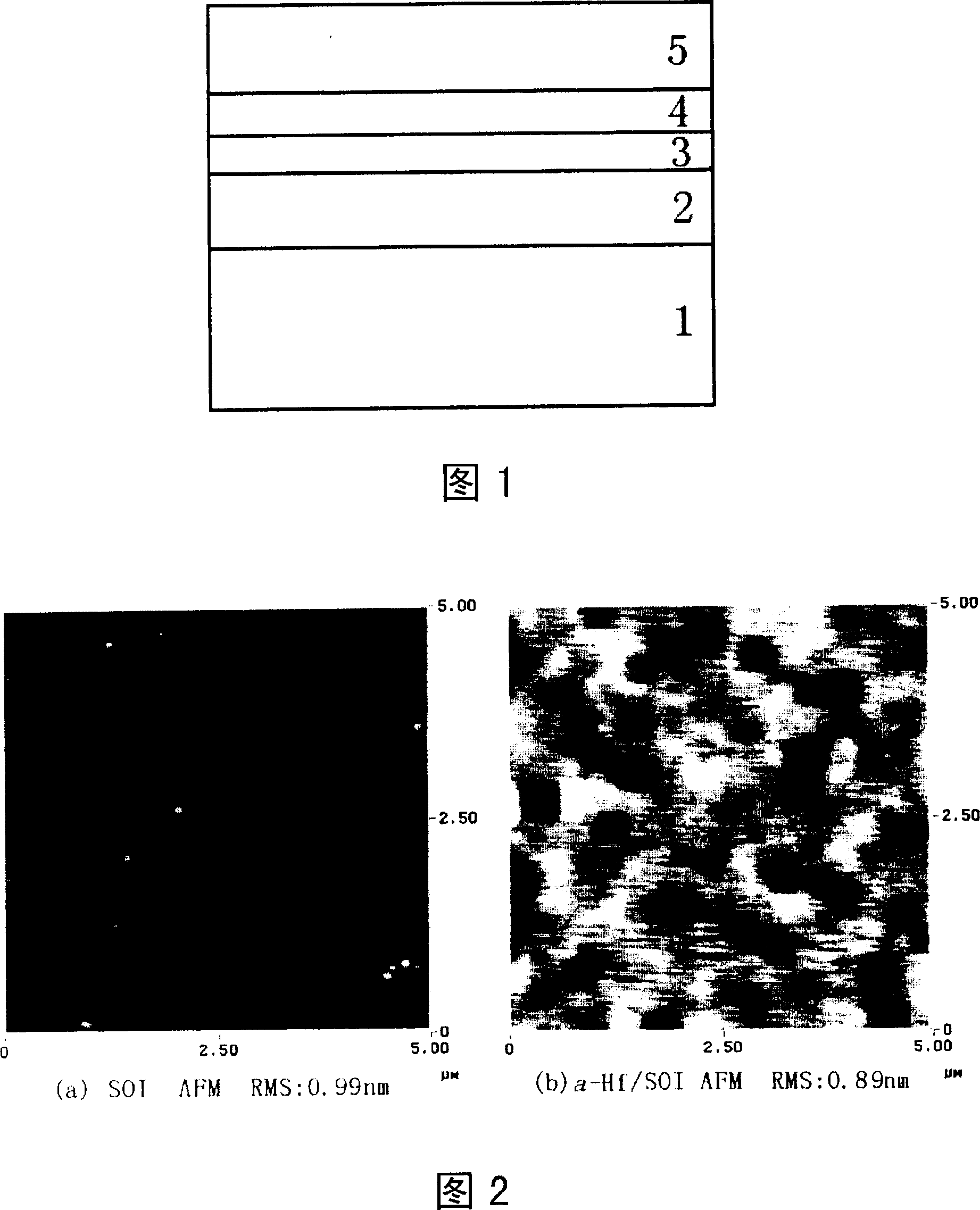

[0043] (1) A conventional SOI covariable substrate was selected for the preparation of an SOI type composite covariable layer substrate. Figure 1 is a schematic structural diagram of an SOI type composite covariable layer substrate. The main technical parameters are shown in Table 1.

[0044] Table 1: Main Technical Parameters of SOI Composite Covariable Layer Substrates

[0045] SOI

composite

covariant

layer substrate

SOI

Can

Association

Change

lining

end

bottom branch

Supporting substrate 1

Material

Silicon (Si)

Thickness (μm)

300-5

00

crystal quality

intermediate solution

coupling layer 2

Material

Thickness (nm)

200-6

00

crystal quality

amorphous or polycrystalline

top covariant

Layer 3

Material

Silicon (Si)

Thickness (nm)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com