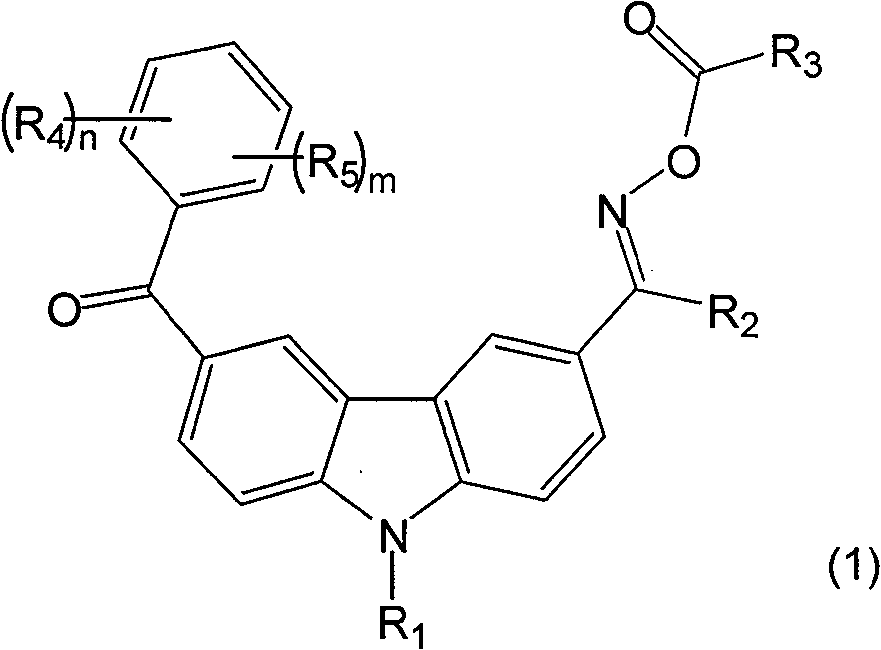

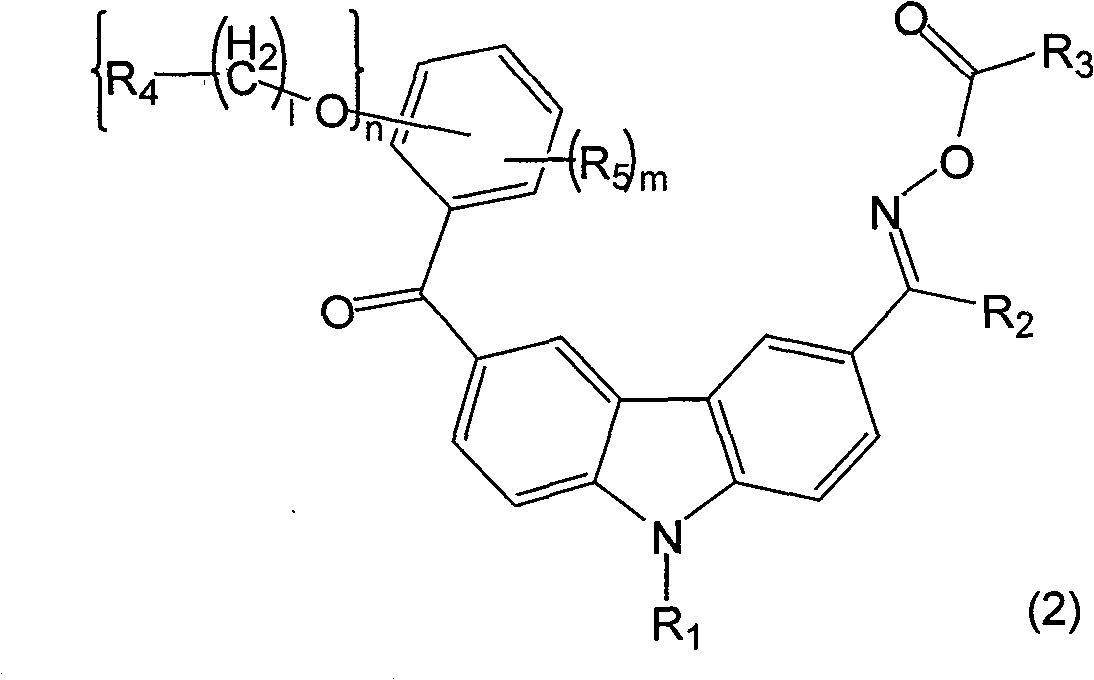

Radiation-sensitive resin composition, protrusion and spacer formed of the same, method of forming the radiation-sensitive resin composition, and liquid crystal display element

A technology for liquid crystal display elements and separators, which is applied in electrical components, static indicators, photosensitive material processing, etc., and can solve the problems of time-consuming, reduced production capacity, and low exposure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0241] Hereinafter, the embodiments of the present invention will be described in more detail with examples. Here, parts and% are weight basis.

Synthetic example 1

[0243] In a flask equipped with a cooling tube and a stirrer, add 5 parts of 2,2'-azobisisobutyronitrile and 250 parts of diethylene glycol methyl ethyl ether, and then add 35 parts of 2-methacryloxyethyl Succinic acid, 25 parts of n-butyl methacrylate, 35 parts of benzyl methacrylate, after nitrogen replacement, add 5 parts by weight of 1,3-butadiene, stir slowly and raise the temperature of the solution to 90°C The temperature was maintained for 5 hours for polymerization to obtain a [A] copolymer solution with a solid content concentration of 28.0%. Let this be [A-1] polymer.

[0244] The obtained polymer [A-1] measured Mw using GPC (Gel Permeation Chromatography) HLC-8020 (trade name, manufactured by Tosoh Co., Ltd.) and found to be 12,000.

Synthetic example 2

[0246] In a flask equipped with a cooling tube and a stirrer, 5 parts by weight of 2,2'-azobis (2,4-dimethylvaleronitrile) and 200 parts by weight of diethylene glycol methyl ethyl ether were added, and then 18 Parts by weight of methacrylic acid, 40 parts by weight of glycidyl methacrylate, 5 parts by weight of styrene, 32 parts by weight of tricyclic methacrylic acid [5.2.1.0 2,6 ] After replacing the dec-8-yl ester with nitrogen, add 5 parts by weight of 1,3-butadiene, stir slowly and raise the temperature of the solution to 70°C, keep the temperature for 5 hours for polymerization to obtain a copolymer [ A-2] solution.

[0247] The solid content concentration of this solution was 33.0% by weight, and the Mw of the copolymer [A-2] was 11,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com