Gear and manufacturing method for a gear

A gear and ring gear technology, applied in the direction of gears, components with teeth, belts/chains/gears, etc., can solve problems such as gear teeth breakage, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

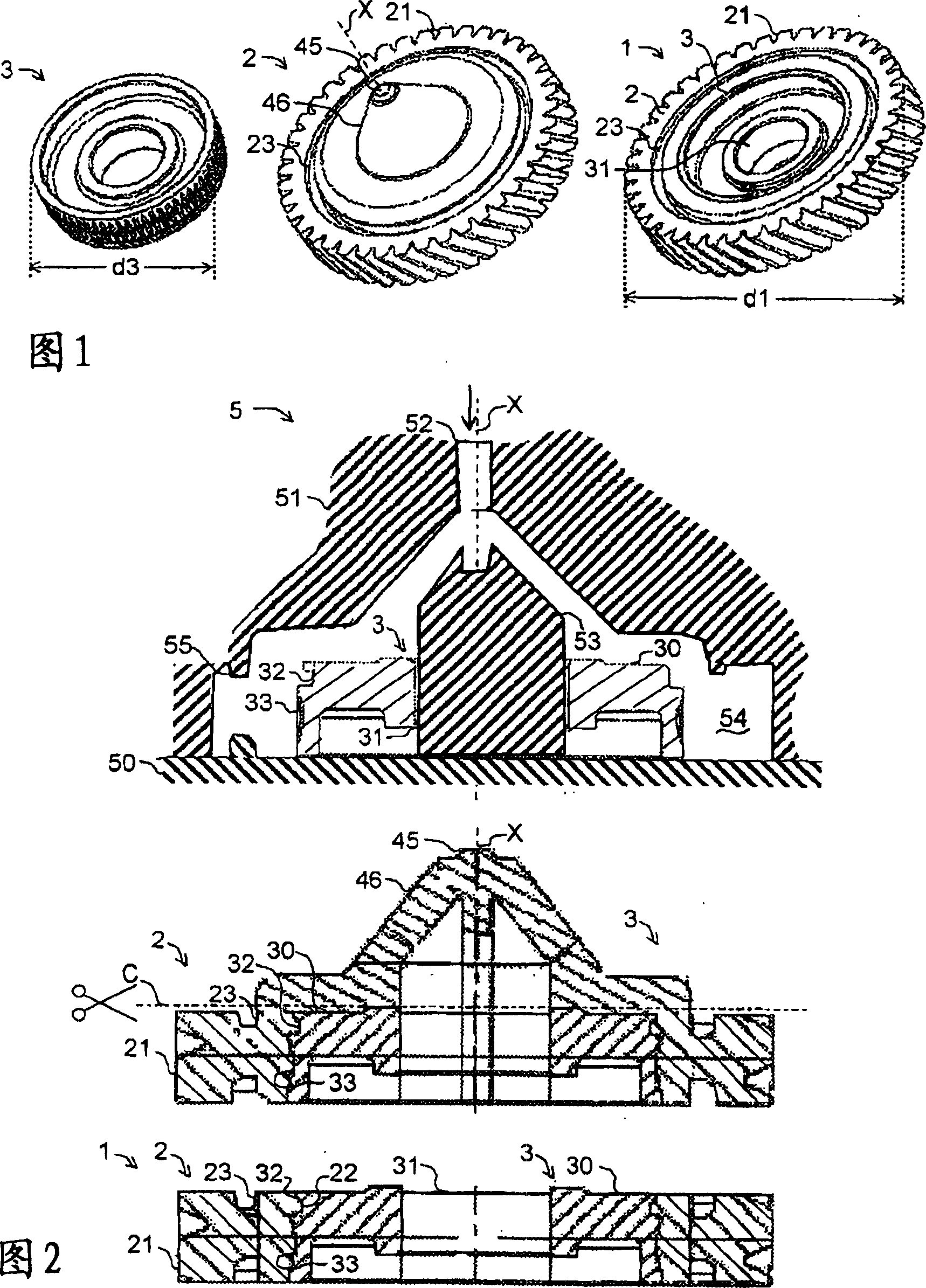

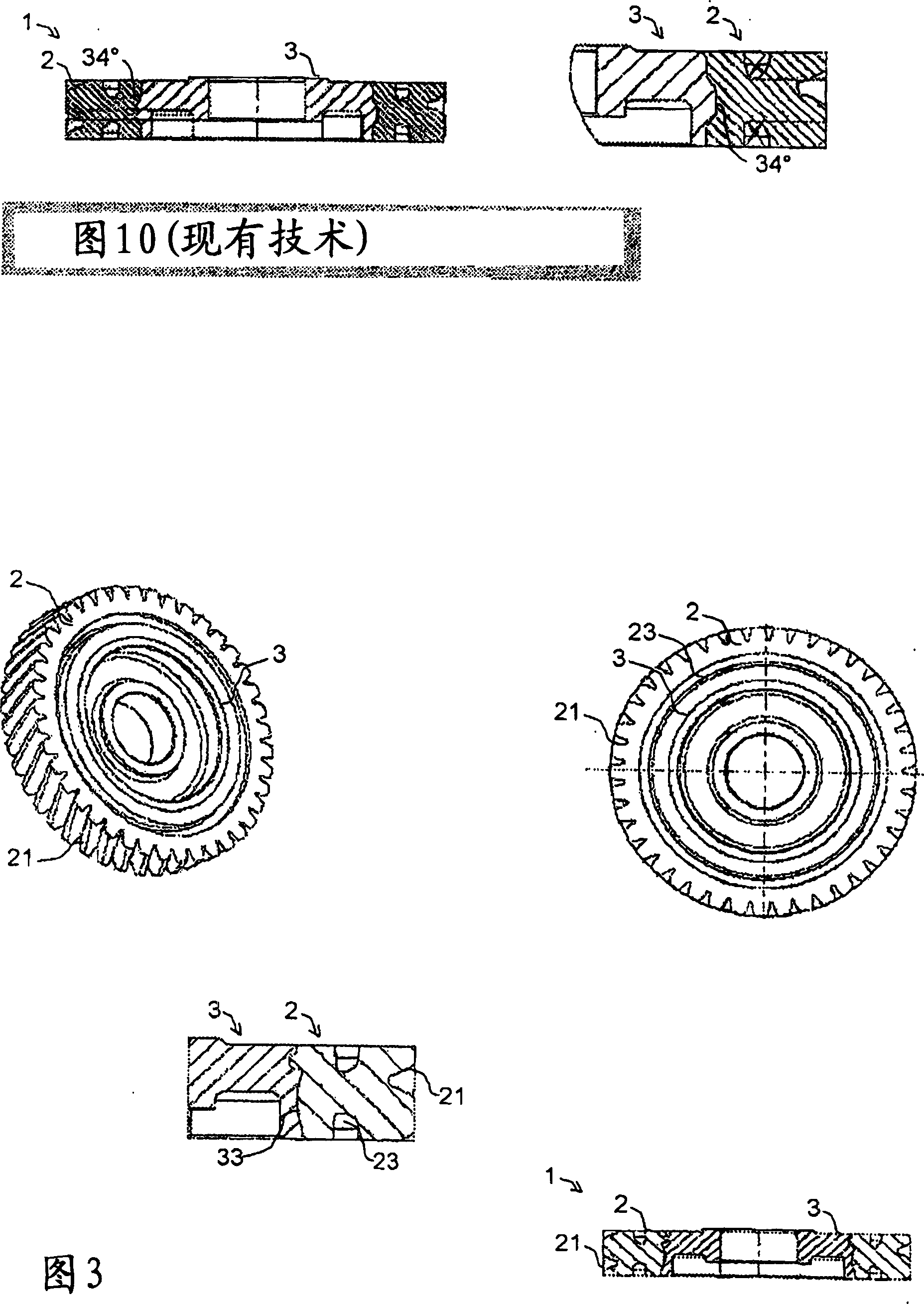

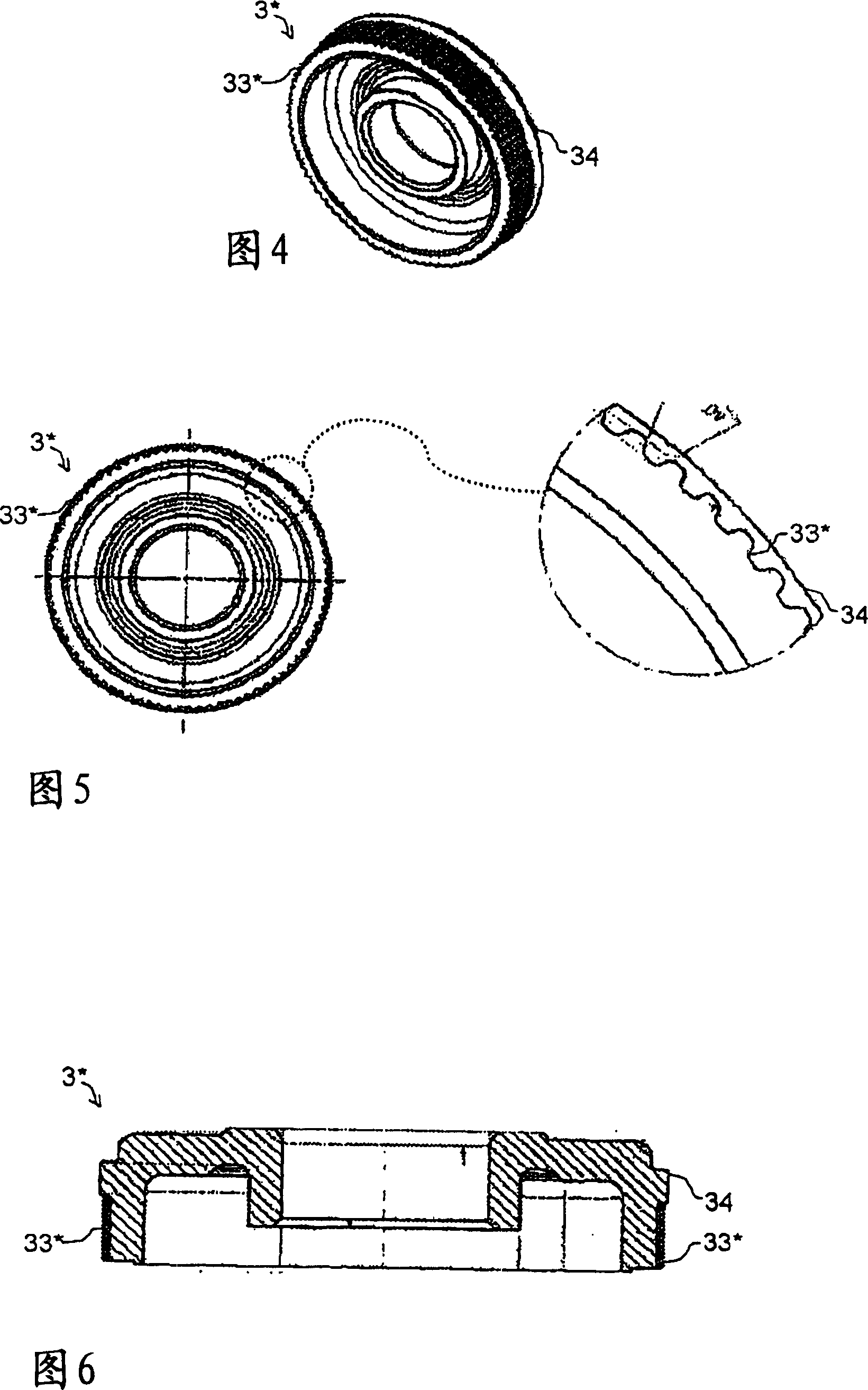

[0036] As shown in FIG. 1 , an exemplary gear 1 is manufactured using a number of manufacturing steps. In a first manufacturing step, inserts 3 are provided, which are used to construct the actual hub. The insert 3 is preferably an insert made of metal, in particular steel, for example for the construction of a steel wheel hub known per se.

[0037] In a subsequent production step, the insert 3 is injection-molded to form the toothed ring 2 , wherein the injection-molding is performed using an umbrella casting method. Correspondingly, the figure in the middle shows the insert completely injection-molded with plastic in the view direction, which already has the toothing structure 21 in the circumferential direction. Such a gear tooth structure 21 can be poured directly and synchronously. During the umbrella casting, the insert 3 is injection-moulded axially from the axis X, which is preferably the axis of rotation of the gear. The figure shows the side from which the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com