Cushion separation facility for mud blank

A separation device and mold technology, applied in unloading devices, manufacturing tools, etc., can solve the problems of adjustment, no buffer, unsatisfactory ventilation and drying, etc., and achieve the effects of avoiding damage, reducing work intensity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

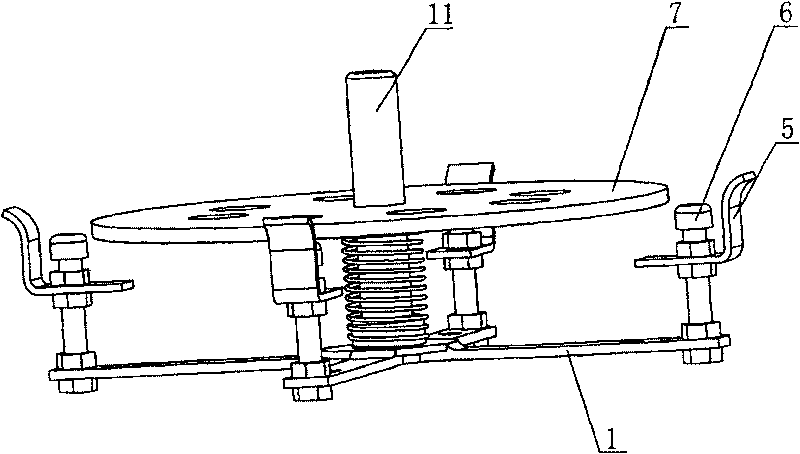

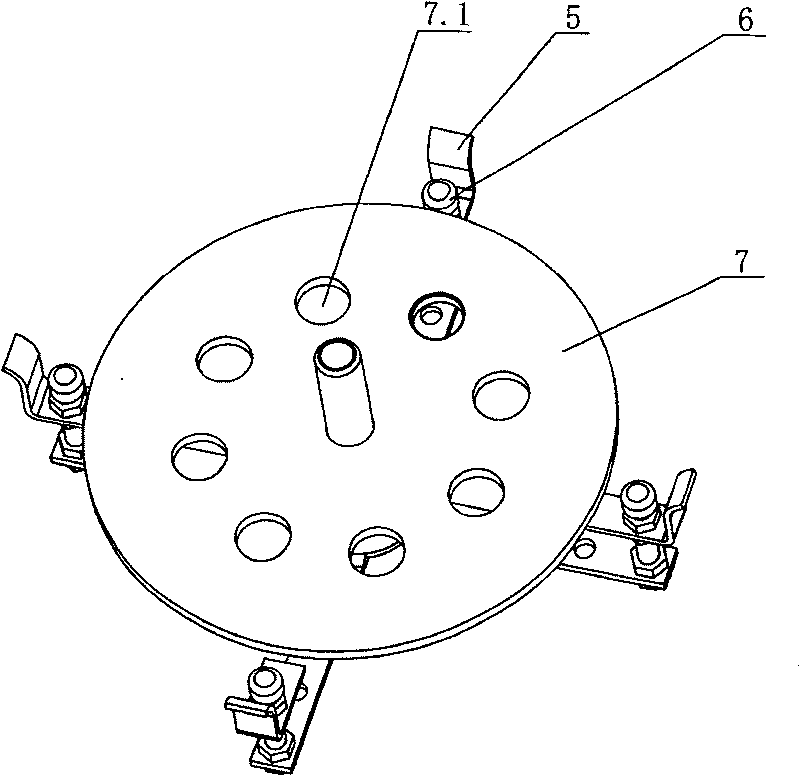

[0020] In the figure, 1 is the connecting bracket, 1.1 is the adjustment hole, 2 is the screw rod, 3 is the fixing nut, 4 is the lock nut, 5 is the height adjustment plate for degerming, 6 is the protective cover, 7 is the supporting plate, and 7.1 is the air hole , 8 is a positioning post, 9 is a buffer spring, 10 is a limit sleeve, and 11 is a guide post.

[0021] see Figure 1-Figure 3 , the cushioning and separating device for the mud base mold includes a supporting plate 7, and the supporting plate is provided with a vent hole 7.1, eight vent holes 7.1, arranged circularly on the supporting plate 7, or arranged in layers inside and outside. The supporting plate 7 and elastic The adjustment mechanism is connected. The elastic adjustment mechanism includes a connecting bracket 1, and the connecting bracket 1 is in the shape of a line, a Y shape, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com