Method and equipment for disassembling components entirely from waste circuit board

A technology for waste circuit boards and circuit boards, which is used in electrical components, welding equipment, metal processing equipment, etc., and can solve problems such as impossible sealing, effective disassembly, and damage to components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Example 1 According to Method 1, the waste circuit board with components on both sides is disassembled

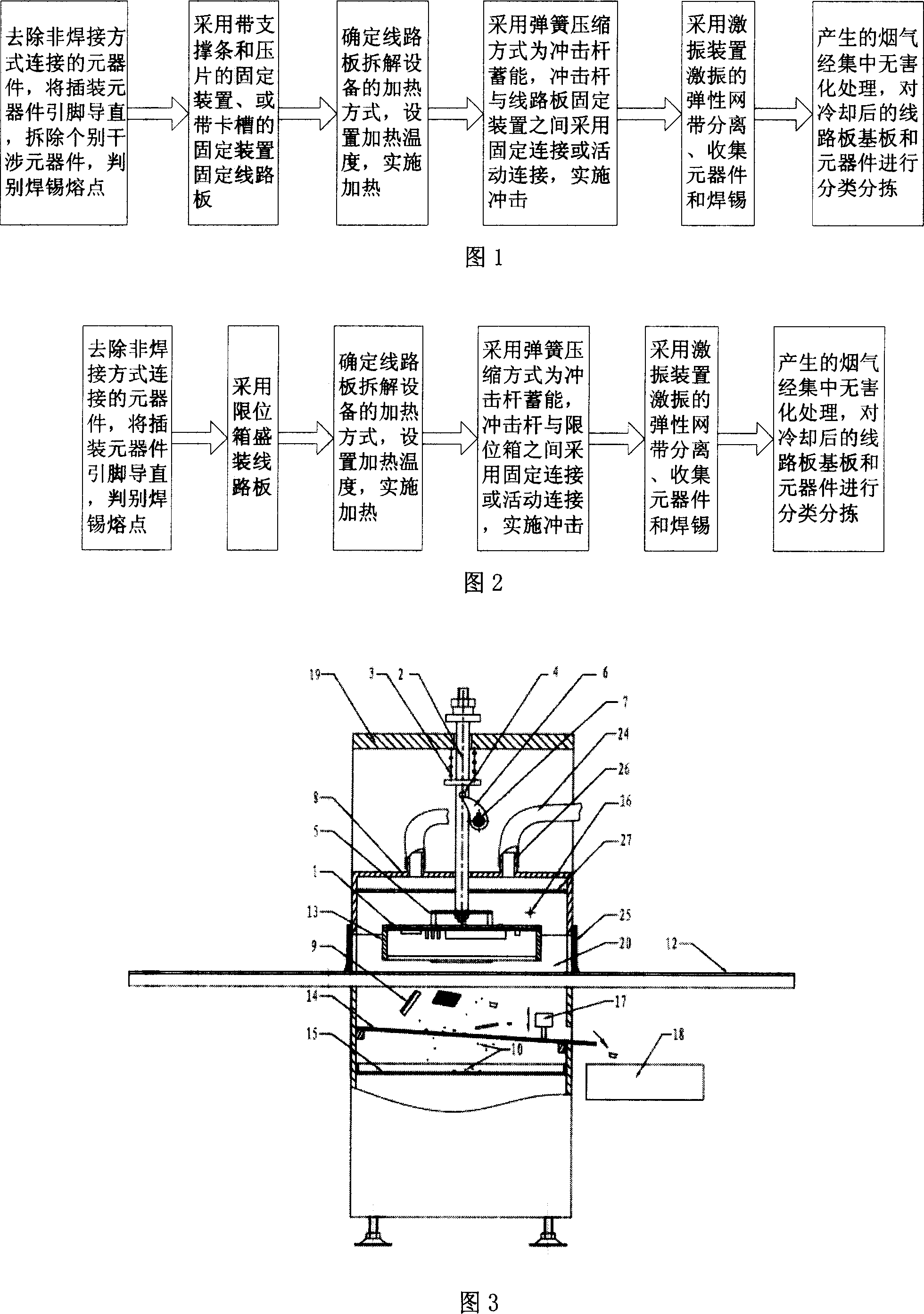

[0090] A kind of method that components and parts are integrally disassembled from waste circuit board, (Fig. 1 is the schematic flow chart of first method provided by the present invention) this method comprises the following steps:

[0091] 1) Take a waste circuit board with components on both sides (hereinafter referred to as the circuit board), and clean the circuit board such as dust removal and dirt removal; remove the components connected by non-welding methods such as buckle connection, direct insertion, and screw connection; Straighten the pins of the plug-in components to be removed on the circuit board so that they are basically perpendicular to the circuit board substrate; roughly determine the melting point temperature of the solder (solder paste) used for the circuit board according to the type of circuit board substrate and the model of the component ;...

Embodiment 2

[0097] Example 2 According to the second method, the waste circuit board with components on both sides is disassembled

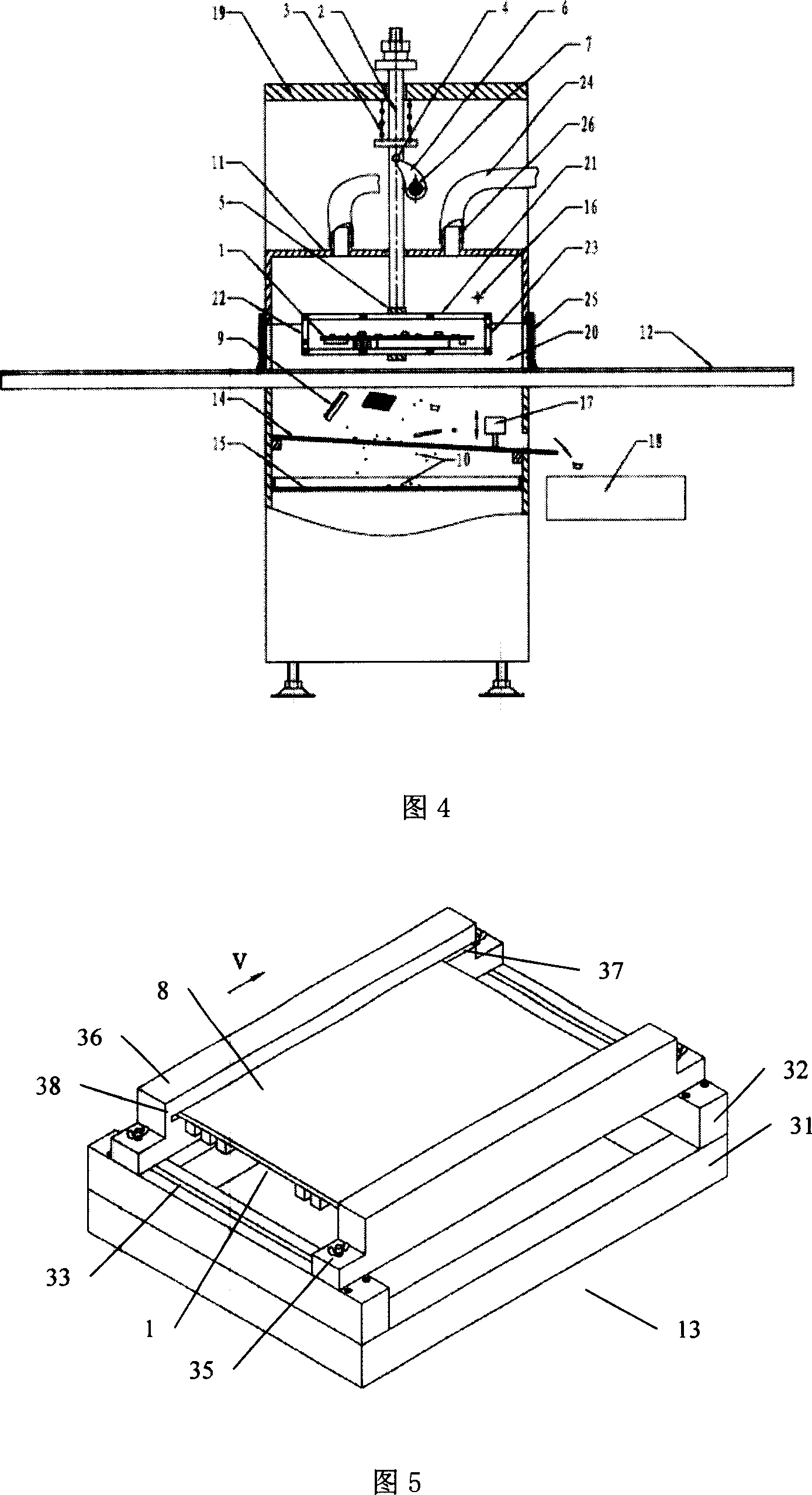

[0098] A kind of method that components and parts are integrally disassembled from waste circuit board, (Fig. 2 is the schematic flow chart of the second method provided by the present invention) this method comprises the following steps:

[0099] 1) Take a waste circuit board with components on both sides, and clean the circuit board such as dust and dirt; Guide the pins of the plug-in components so that they are basically perpendicular to the circuit board substrate; roughly determine the melting point temperature of the solder (solder paste) used for the circuit board according to the type of circuit board substrate and the model of the component;

[0100] 2) Use a limit box to contain the circuit board: set a cuboid box, the internal cavity of the cuboid box is larger than the circuit board, and the six sides are hollow and made into a grid shape. The co...

Embodiment 3

[0105] Embodiment 3 and Embodiment 4 illustrate the present invention centering on the equipment.

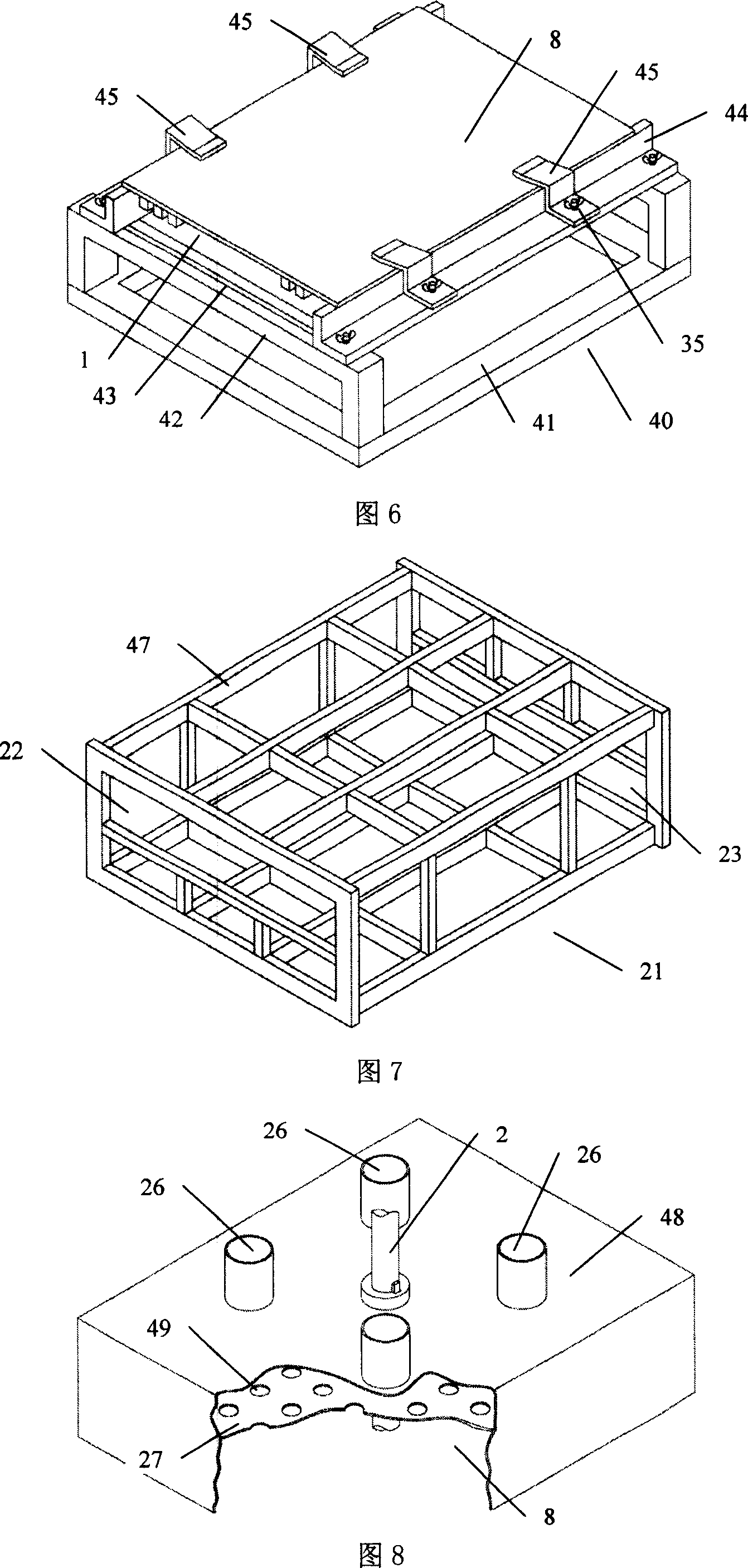

[0106] Embodiment 3 circuit board dismantling equipment one

[0107] Fig. 3 is a schematic structural diagram of circuit board dismantling equipment 1. The dismantling equipment adopts a fixing device 13 with a slot to fix the circuit board; Fig. 5 is a schematic diagram of a circuit board fixing device with a slot (Fig. 6 is a schematic diagram of a circuit board fixing device with a support bar and a pressing sheet). A heating and heat preservation area 20 is set, and the impact rod 2 is pushed by the cylindrical pin 4 to move by rotating the cam 6, so that the spring 3 is compressed to store energy. Separation and collection of components and solder are carried out on the metal mesh belt which is set obliquely and excited by the exciter, so as to realize the integral removal of plug-in components and SMD components on the circuit board based on functions. The dismantling eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com