Desulfurization refining method for ammonia gas containing hydrogen sulfide and ammonia gas finisher

A refining method and technology of hydrogen sulfide, which are applied in the preparation/separation of ammonia, chemical instruments and methods, separation methods, etc., to achieve good refining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

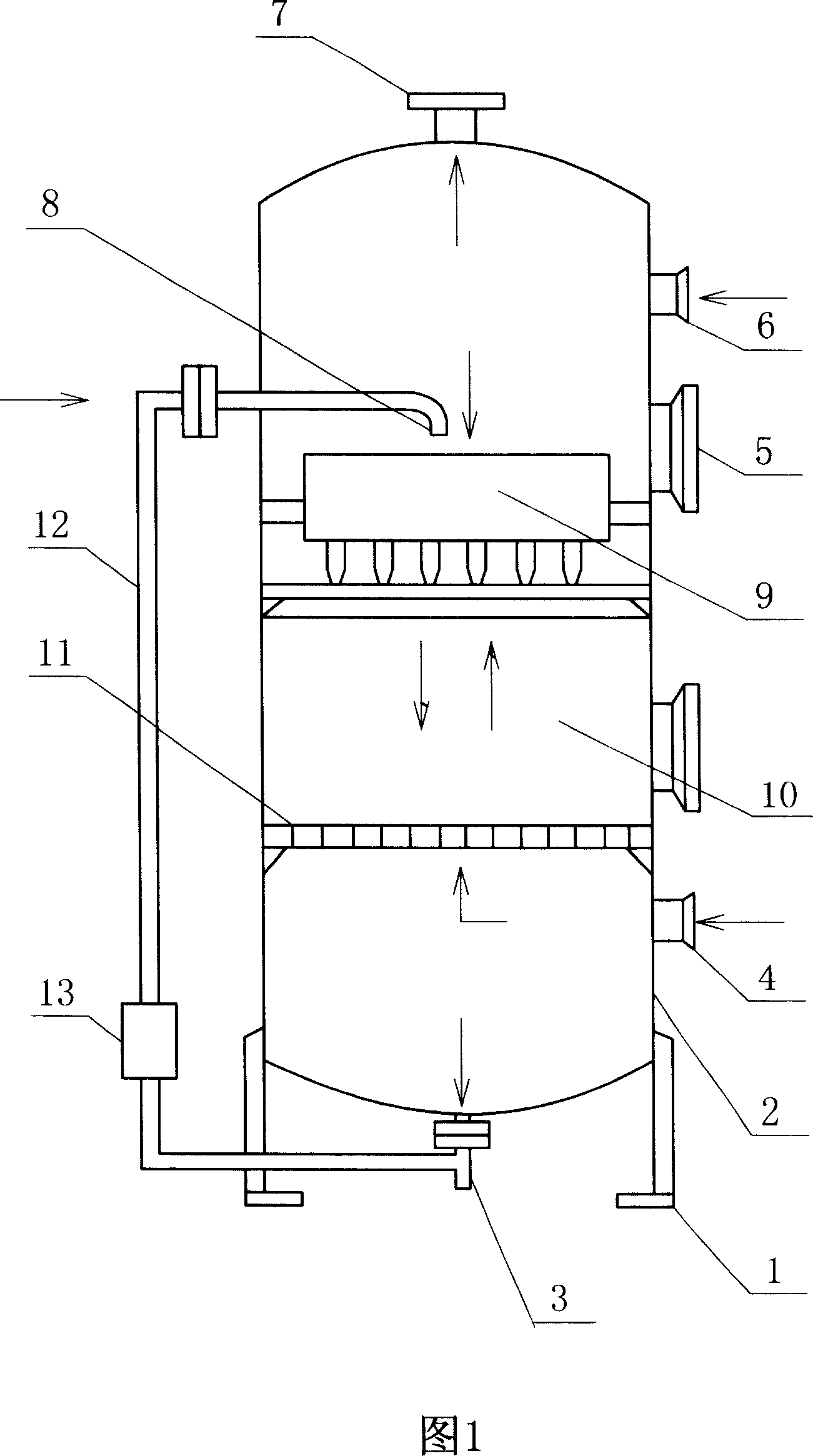

[0019] A. The structure of the ammonia refiner:

[0020] As shown in Figure 1, the ammonia refiner body 2 is installed on the support 1, the liquid outlet 3 is connected to the lower side, and the ammonia gas inlet 4 containing hydrogen sulfide, the human body inlet and outlet 5 and the water inlet 6 are connected to the side. The top is connected with a gaseous ammonia outlet 7, a support plate 11 is installed in the lower middle of the inner cavity of the ammonia refiner, and a distributor 9 is installed on the upper part of the inner cavity of the ammonia refiner. The space between the support plate and the distributor constitutes a refining area. The reflux ammonia liquid inlet 8 installed on the upper part of the distributor passes through the wall of the ammonia refiner and is placed above the distributor, and communicates with the outlet pipe 3 through the return pipe 12 and the return pump 13 .

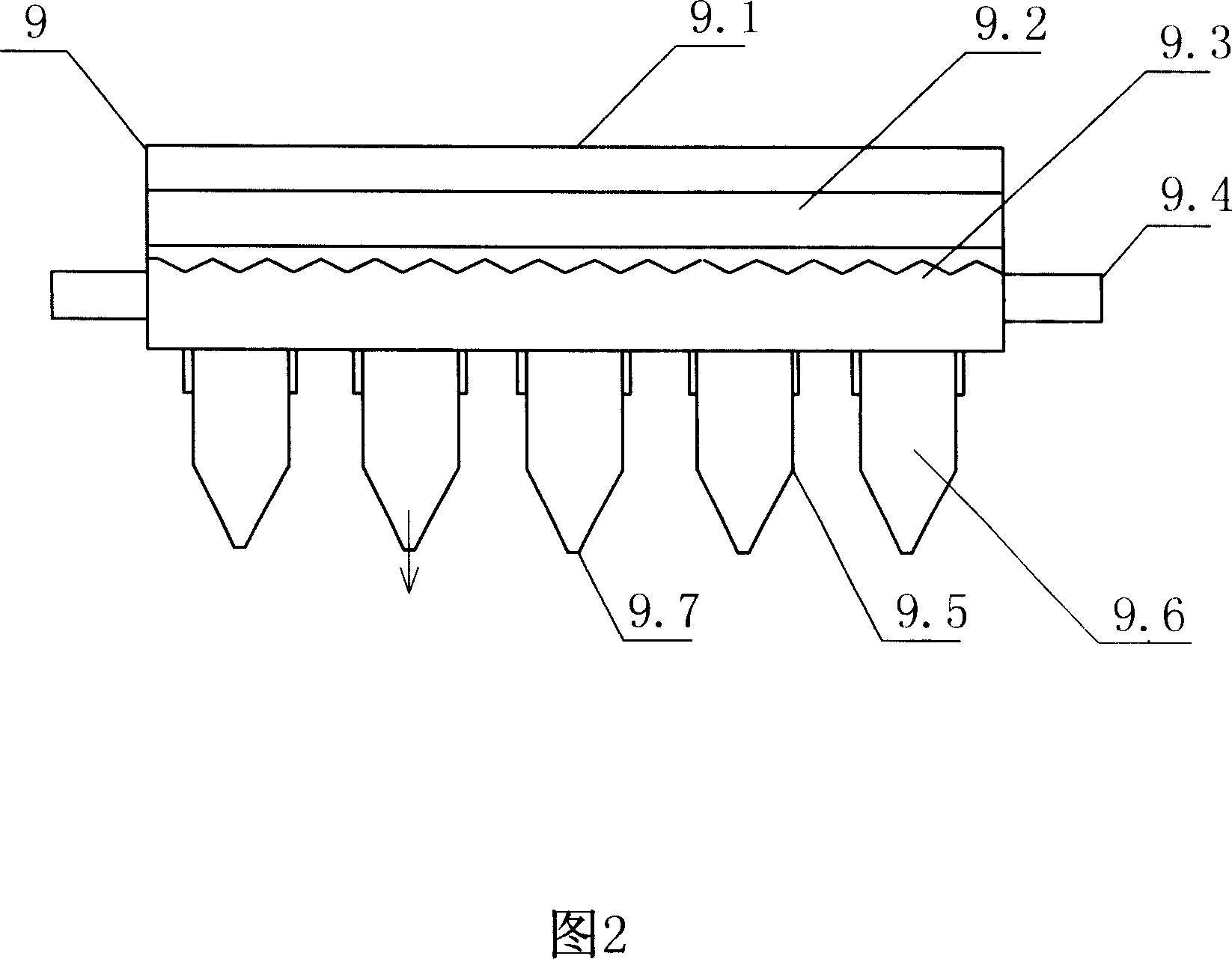

[0021] As shown in Figure 2: a liquid inlet 9.1 is provided on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com