Method for preparing natural milk taste condiment and natural milk taste condiment made thereof

A technology of milk fragrance and fragrance, which is applied in the direction of milk preparations, dairy products, food preparation, etc., and can solve the problems of unnatural aroma and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

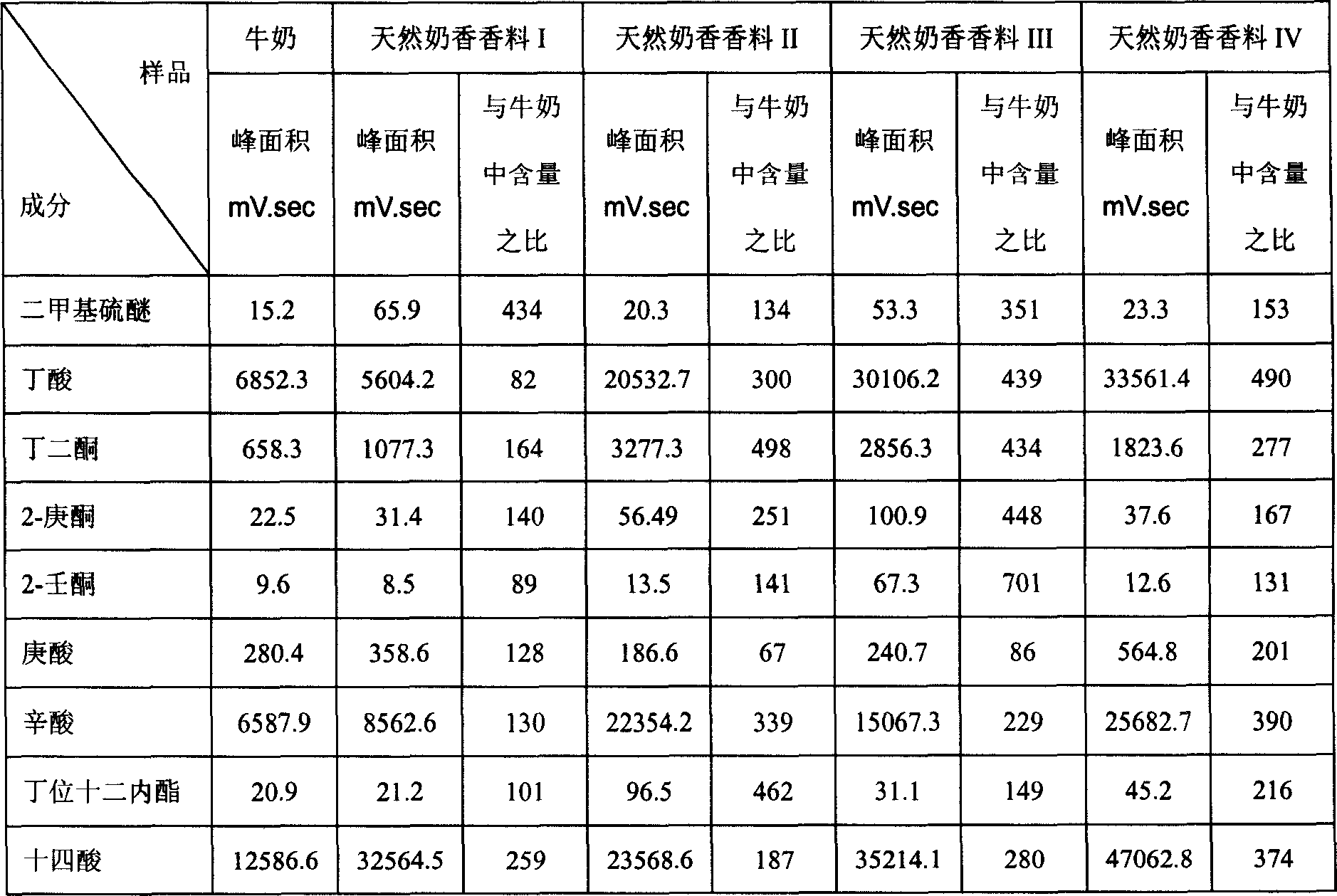

[0030] Take 1000 grams of fresh milk, after sterilization, add 10 grams of Lactobacillus bulgaricus and 10 grams of Streptococcus lactis, ferment at 30°C for 24 hours, heat and sterilize the fermentation liquid, concentrate to 200 grams, add 100 grams of Water cream, emulsified and homogenized, adjusted pH to 7.0 with sodium citrate, added 0.3 g of protease, 0.3 g of lipase, enzymolyzed at 50°C for 12 hours, inactivated at high temperature, emulsified and homogenized to obtain natural milk flavor I. The product has a typical condensed milk aroma with a natural and soft aroma.

Embodiment 2

[0032] Take 1000 grams of fresh milk, after sterilization, add 50 grams of Streptococcus lactis strains, ferment at 37 °C for 6 hours, heat and sterilize the fermentation liquid, concentrate to 400 grams, add 400 grams of anhydrous butter, emulsify and homogenize, use Adjust the pH to 5.5 with sodium citrate, add 0.6 g of lipase, enzymatically hydrolyze at a constant temperature of 40°C for 6 hours, inactivate the enzyme at high temperature, emulsify and homogenize, and obtain the natural milk fragrance II. The product has a typical creamy aroma with a natural and vivid aroma.

Embodiment 3

[0034] Take 1000 grams of fresh milk, after sterilization, add 20 grams of Lactobacillus bulgaricus and 20 grams of Streptococcus lactis, ferment at 30°C for 6 hours, heat and sterilize the fermentation liquid, concentrate to 200 grams, add 50 grams of Water cream, emulsified and homogenized, adjusted pH to 7.0 with sodium citrate, added 0.5 g of protease, 0.1 g of lipase, enzymatically hydrolyzed at 60°C for 24 hours, inactivated at high temperature, emulsified and homogenized to obtain natural milk flavor III. The product has a typical cheese aroma with a natural and strong aroma.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com