Microbial fertilizer and its prepn process and application

A technology of microbial fertilizer and inoculation amount, applied in the direction of organic fertilizers and bacteria, can solve the problems of affecting the absorption of effective nutrients, destroying the balance of tobacco flora, and failing to cure, so as to inhibit the occurrence of insect pests and accelerate the rate of cell division , Accelerate the effect of cell expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

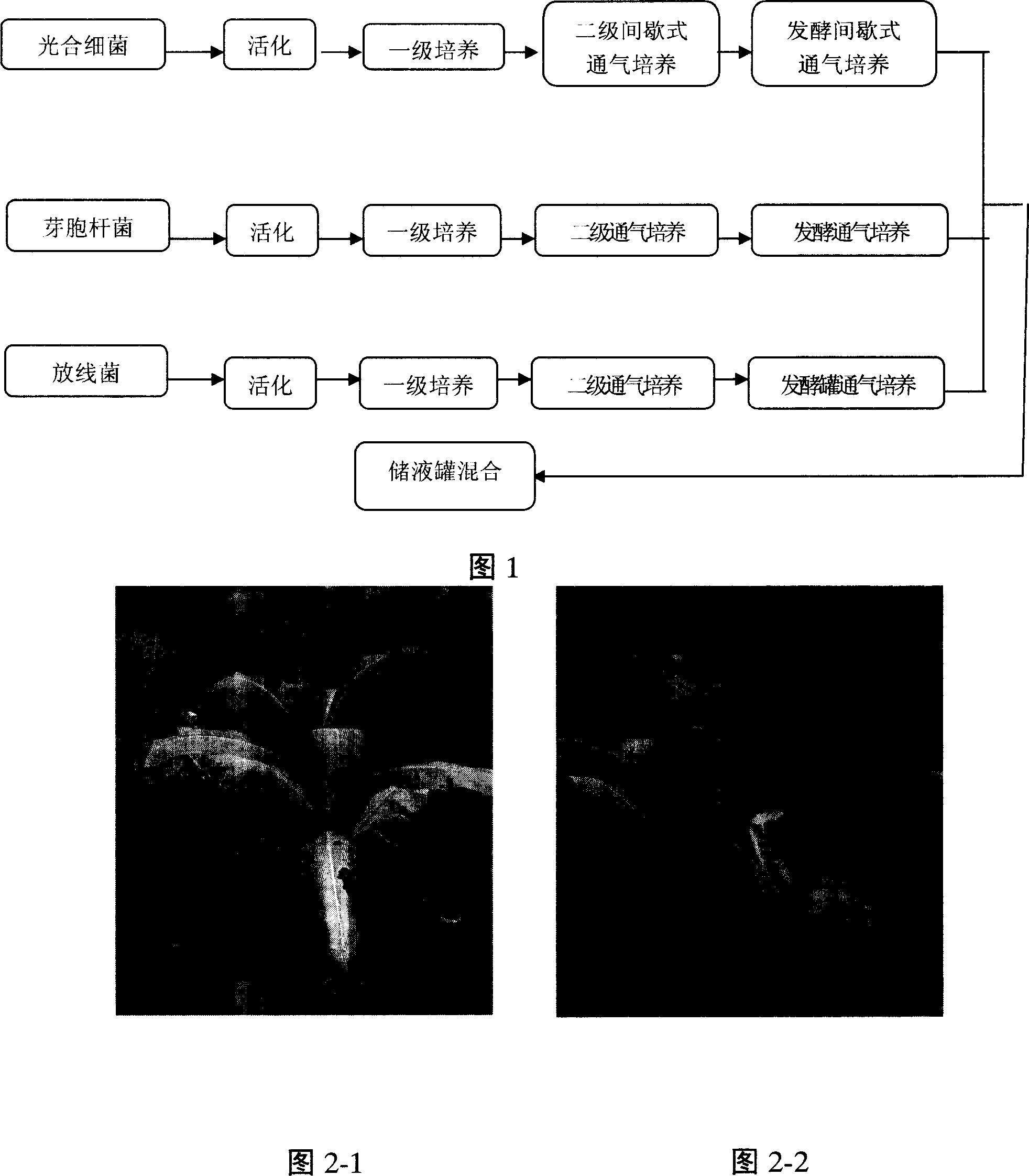

Method used

Image

Examples

Embodiment 1

[0049] The production conditions of each fermentation broth are shown in Table 1.

[0050] Among them, the light intensity of the photosynthetic bacterium Rhodopseudomonas palustris was 3000 lux during the cultivation process.

[0051] Table 1

[0052]

[0053] Take four kinds of fermented and qualified bacterial liquid volumes by volume: 150 liters of Rhodopseudomonas palustris, 150 liters of Bacillus subtilis, 700 liters of Streptomyces Jingyang, 150 liters of Lactobacillus acidophilus, and put them into the liquid storage tank , the finished product is obtained after mixing the bacterial solution in the liquid storage tank evenly.

Embodiment 2

[0055] The production conditions of each fermentation broth are shown in Table 2.

[0056] Among them, the light intensity during the cultivation of the photosynthetic bacterium Rhodobacter sphaeroides was 4000 lux.

[0057] Table 2

[0058]

[0059] one

[0060] Take four kinds of fermented and qualified bacterial liquid volumes by volume: 100 liters of Rhodopseudomonas palustris, 100 liters of Bacillus subtilis, 2000 liters of Streptomyces Jingyang, 100 liters of Lactobacillus acidophilus, and put them into the liquid storage tank , the finished product is obtained after mixing the bacterial solution in the liquid storage tank evenly.

Embodiment 3

[0062] The production conditions of each fermentation broth are shown in Table 3.

[0063] Among them, the light intensity of the photosynthetic bacterium Rhodopseudomonas palustris was 3500 lux during the cultivation process.

[0064] table 3

[0065]

[0066] nourish

[0067] Take four kinds of fermented and qualified bacterial liquid volumes by volume: 1,000 liters of Rhodopseudomonas palustris, 1,000 liters of Bacillus subtilis, 100 liters of Streptomyces Jingyang, 1,000 liters of Lactobacillus acidophilus, and put them into the liquid storage tank , the finished product is obtained after mixing the bacterial solution in the liquid storage tank evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com