Automatic control potato picker

A harvester and potato technology, which is applied in the field of crop harvesting and agricultural mechanization, can solve the problems of high power consumption, low rate of clear potatoes, and large local amplitude, etc., and achieve the effects of avoiding vibration impact, increasing the rate of clear potatoes, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

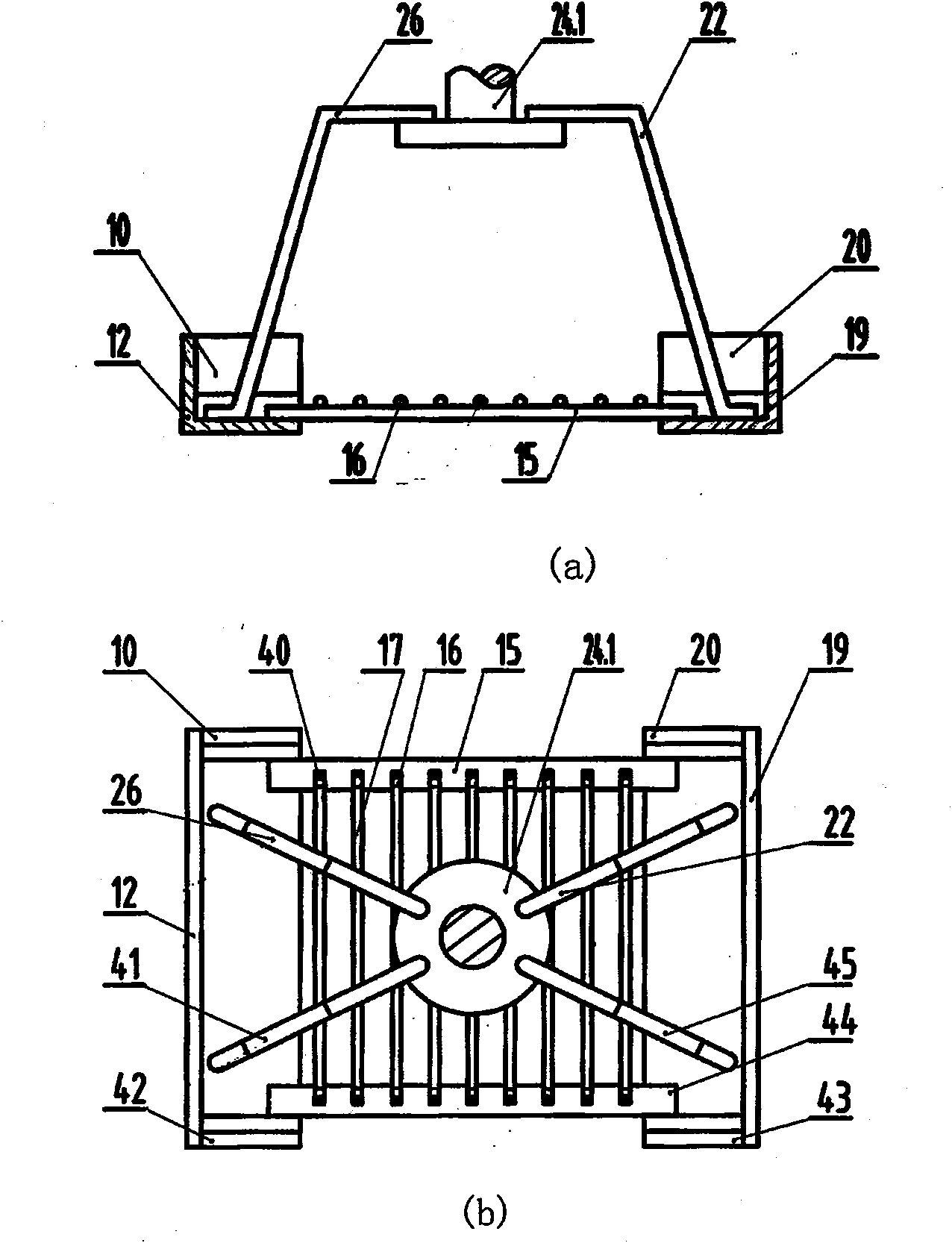

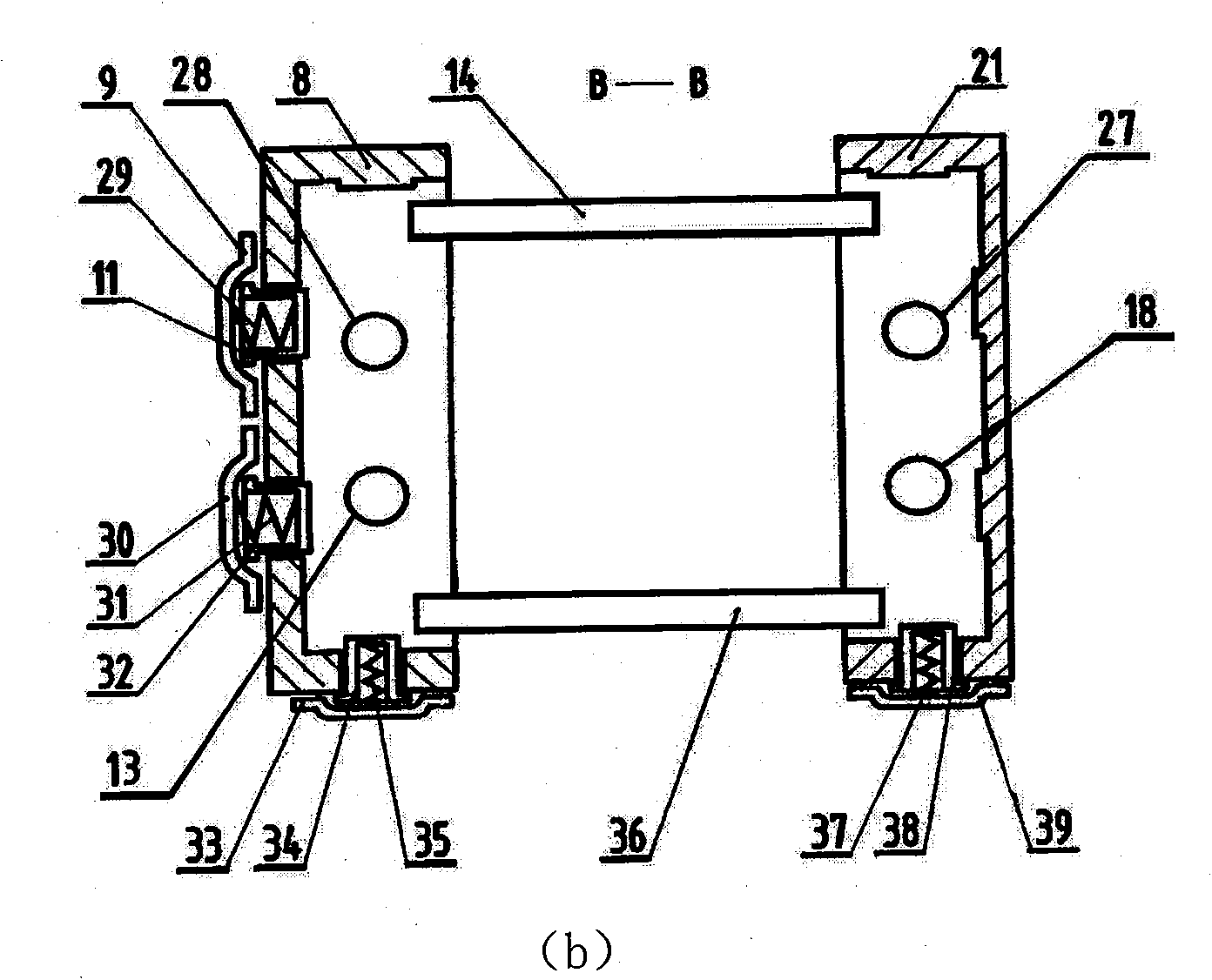

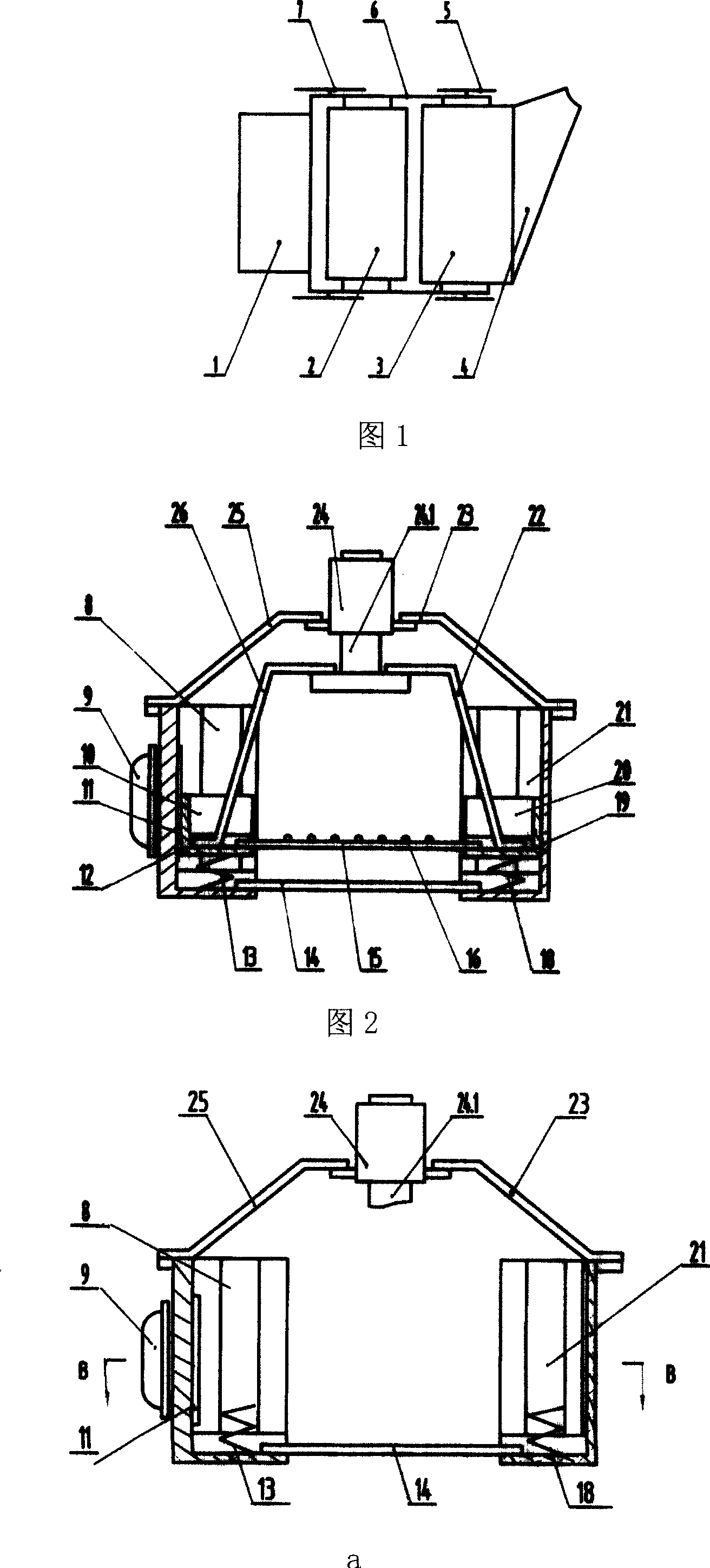

[0024] The invention provides an automatic control potato harvester. exist figure 1 In the top view of the overall structure of the potato harvester shown, the digging shovel 1 and the depth-gauge wheel 7 of the potato harvester are fixed on the front part of the frame 6, and the transmission device 2 is fixed on the frame 6 obliquely upward behind the digging shovel 1 , the potato-soil separation mechanism 3 is fixed on the frame 6 with a slight downward slope behind the transmission device 2, the guide groove 4 is fixed on the connecting plate 14 at the rear and lower part of the potato-soil separation mechanism 3, and the traveling wheels 5 are fixed on the rear of the frame 6 . When working, the potato harvester moves forward, and the digging shovel 1 scoops up the potato soil, and sends it to the transmission device 2 driven by the stepping motor, and the transmission device 2 lifts the potato soil to a specified height and has a relatively high Reasonable speed of move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com