Method and device for controlling vibration intensity

A technology of vibration intensity and negative control, applied in electromechanical devices, control mechanical energy, electric components, etc., can solve problems such as high cost, achieve low cost, and achieve the effect of equipment vibration intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

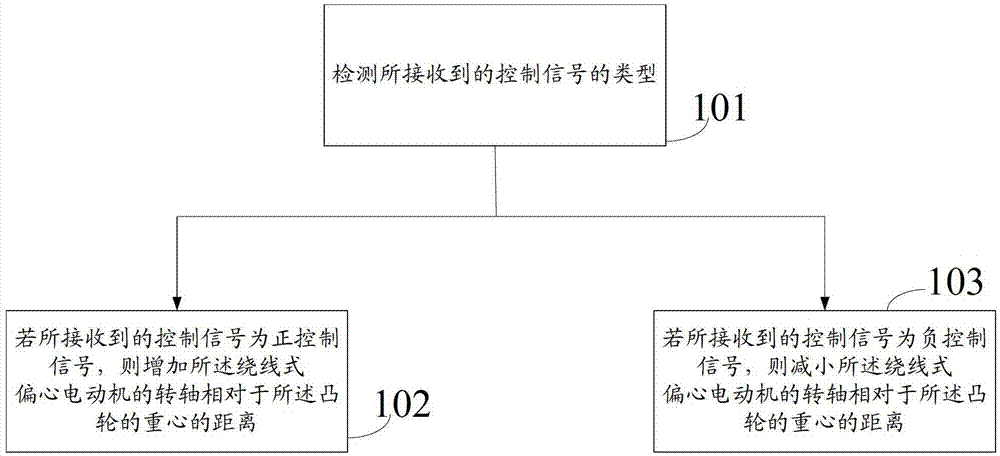

[0027] Embodiments of the present invention provide a method for controlling vibration intensity, such as figure 1 shown, including:

[0028] The method flow described in this embodiment may be executed by a device having a wound eccentric motor.

[0029] Step 101, detecting the type of the received control signal.

[0030] The types of control signals include positive control signals or negative control signals. The positive control signal is used to trigger the device to increase the vibration intensity, and the negative control signal is used to trigger the device to reduce the vibration intensity.

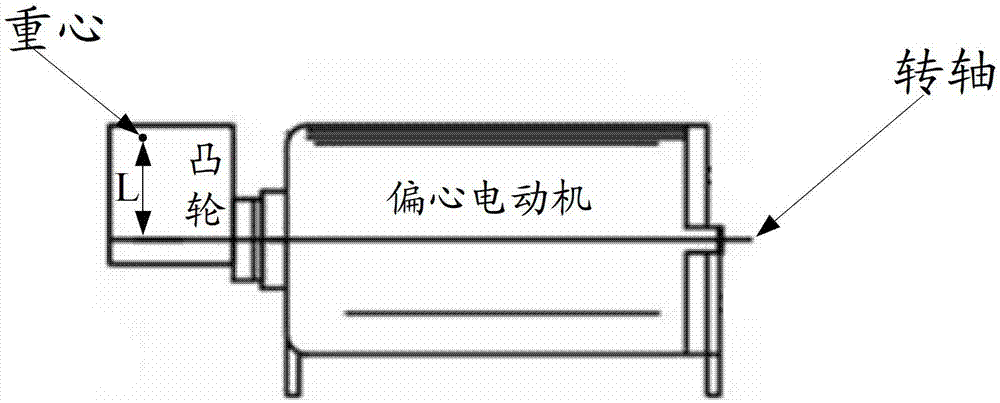

[0031] Specifically, in this embodiment, a device with a wound eccentric motor can receive a control signal, and the control signal can be input by a user or automatically generated by the device with a wound eccentric motor according to specific conditions, for example: The wire eccentric motor device is a small motor used to generate vibration in the mobile phone. Users can...

Embodiment 2

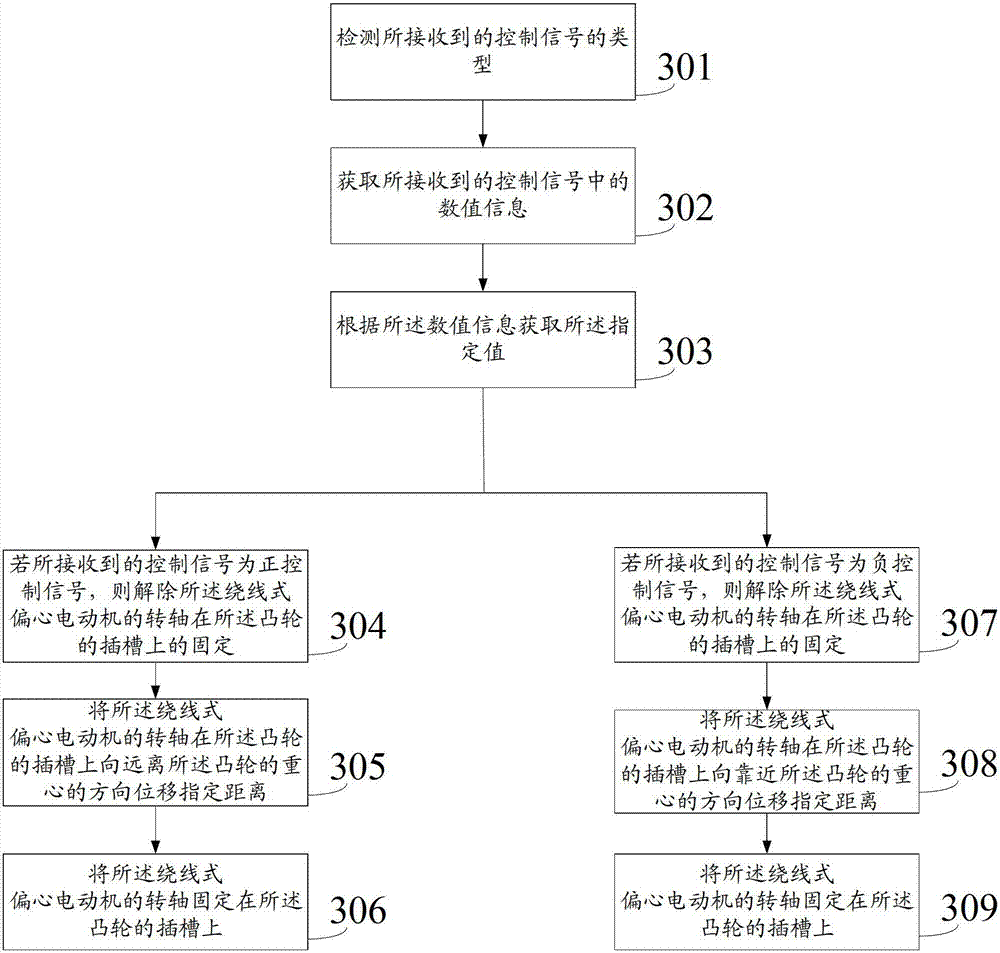

[0040] Embodiments of the present invention provide a method for controlling vibration intensity, such as image 3 shown, including:

[0041] The method flow described in this embodiment may be executed by a device having a wound eccentric motor.

[0042] Step 301, detecting the type of the received control signal.

[0043] The types of control signals include positive control signals or negative control signals. The positive control signal is used to trigger the device to increase the vibration intensity, and the negative control signal is used to trigger the device to reduce the vibration intensity.

[0044] In this embodiment, when the device is not triggered by the control signal, the rotating shaft of the wound eccentric motor is fixed on the slot of the cam, and the slot passes through the center of the cam and the center of gravity of the cam at the same time. E.g:

[0045] In practical applications, the fixing or unlocking of the rotating shaft of the wound eccentri...

Embodiment 3

[0062] Embodiments of the present invention provide a device for controlling vibration intensity, such as Figure 4 shown, including:

[0063] The apparatus in this embodiment can be run on equipment with an eccentric motor.

[0064] The control signal detection module 41 is used to detect the type of the received control signal.

[0065] The types of control signals include positive control signals or negative control signals. The positive control signal is used to trigger the device to increase the vibration intensity, and the negative control signal is used to trigger the device to reduce the vibration intensity.

[0066] The intensity control module 42 is configured to increase the distance of the rotating shaft of the eccentric motor relative to the center of gravity of the cam if the received control signal is a positive control signal, wherein the increased distance is a specified value.

[0067] Further, the intensity control module 42 is also used to control the sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com