Reaction method

A reaction and reaction tank technology, applied in the field of reaction, can solve the problems of fragmentation and wear, limited application range, large bed pressure drop, etc., and achieve the effects of avoiding fragmentation and wear, simple replacement steps, and improved reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

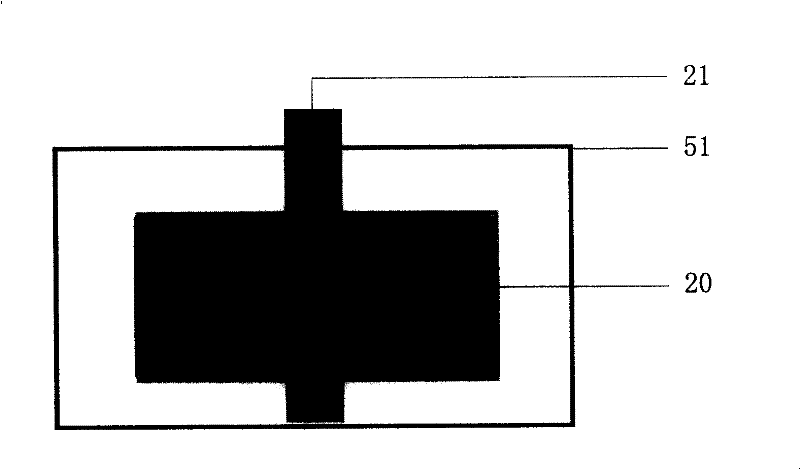

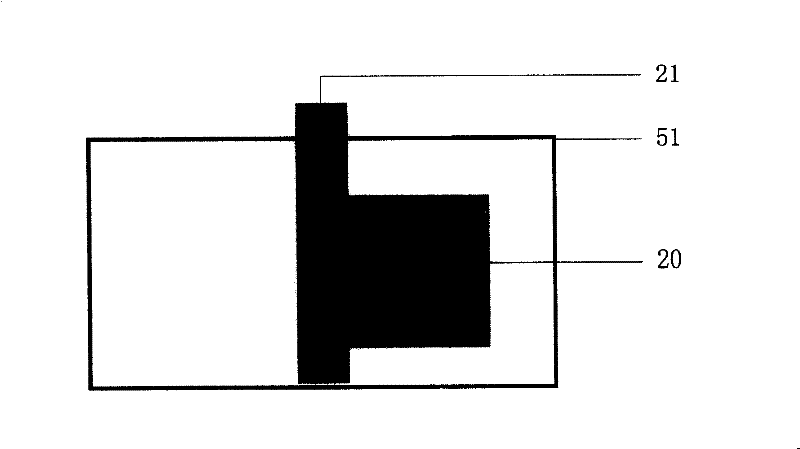

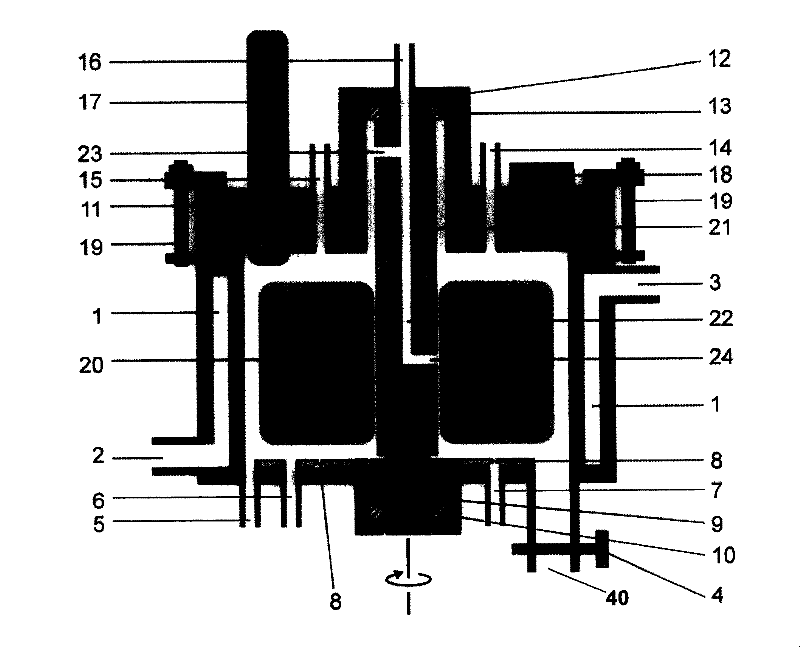

Image

Examples

example 1

[0055] Example 1. Monolithic open-pore D-amino acid oxidase immobilized enzyme is directly used as a stirring blade for batch stirring reaction to prepare glutaryl-7-aminocephalosporanic acid (GL-7-ACA)

[0056] First, prepare the honeycomb-shaped immobilized D-amino acid oxidase block according to the following method.

[0057] D-amino acid oxidase converts cephalosporin C into glutaryl-7-aminocephalosporanic acid (GL-7-ACA). Prepare BL-HS-GHA [E.coli BL21(DE3)pLysS containing recombinant D-amino acid oxidase GHA] E. coli cells according to the following method.

[0058] The source of BL-HS-GHA:

[0059] According to the known Thermoanaerobacterium saccharolyticum glucoseisomerase DNA sequence (GenBank L09699), PCR primers were designed, specifically:

[0060] Upstream primer GI-NdeI:

[0061] 5’-AGCCTAGGTTAATTAACTTTAAGAAGGAGATATACATATGAATAAATATTTTGAGA

[0062] Downstream primer GI-EcoRI:

[0063] 5’-ATAAGCTCAGCGGCGCGCCTTATTCTGCAAACAAATAC

[0064] Using Thermoanaerobacterium saccharolytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com